Reciprocating extrusion type high-efficiency pasture grass cutting device and using method thereof

A cutting device and a technology of reciprocating extrusion, applied in the field of animal husbandry, can solve the problems of low cutting efficiency, complex structure, and difficulty in completing cutting and crushing tasks, and achieve the effects of precise contact, convenient cutting, and avoiding serious forage pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

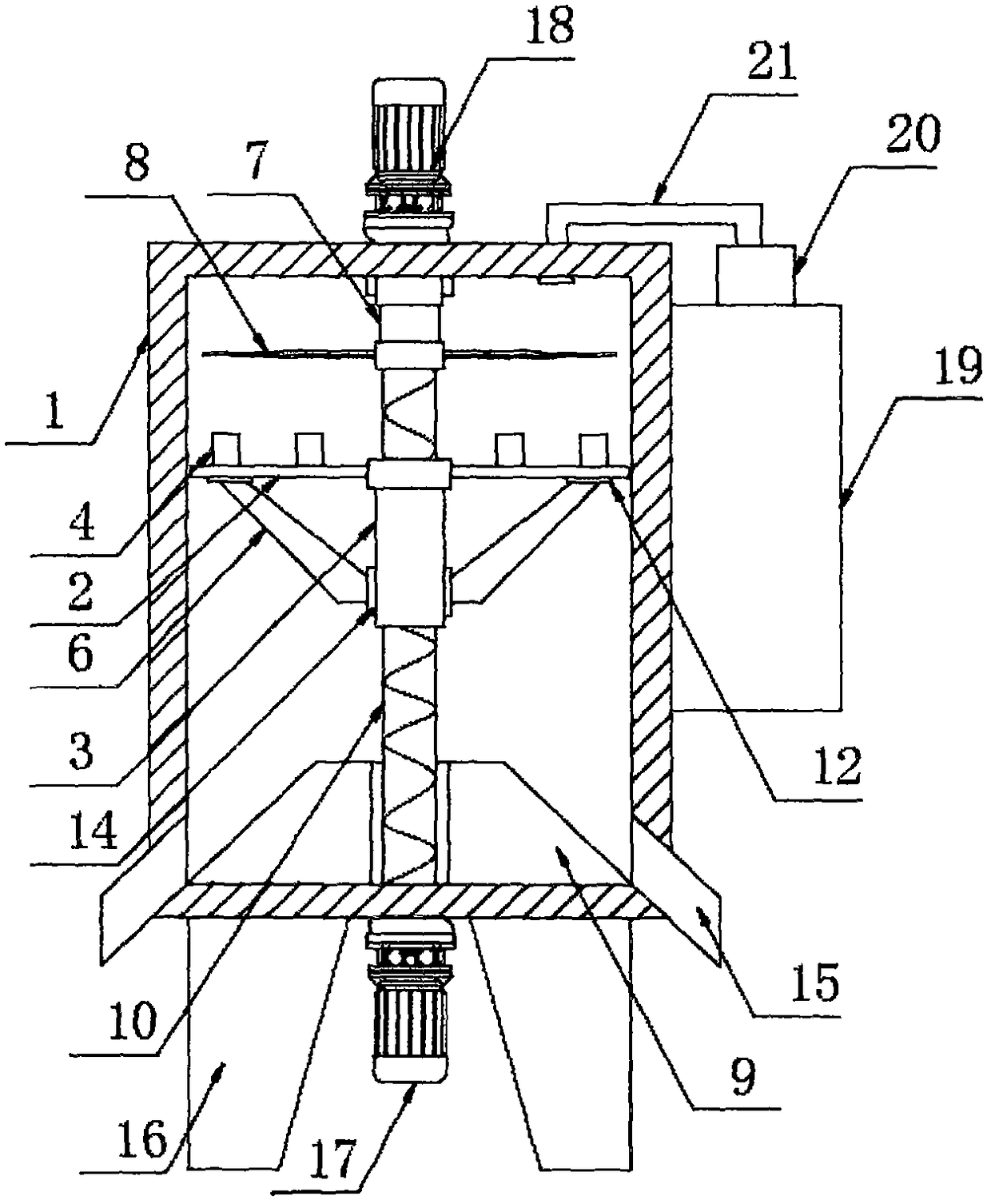

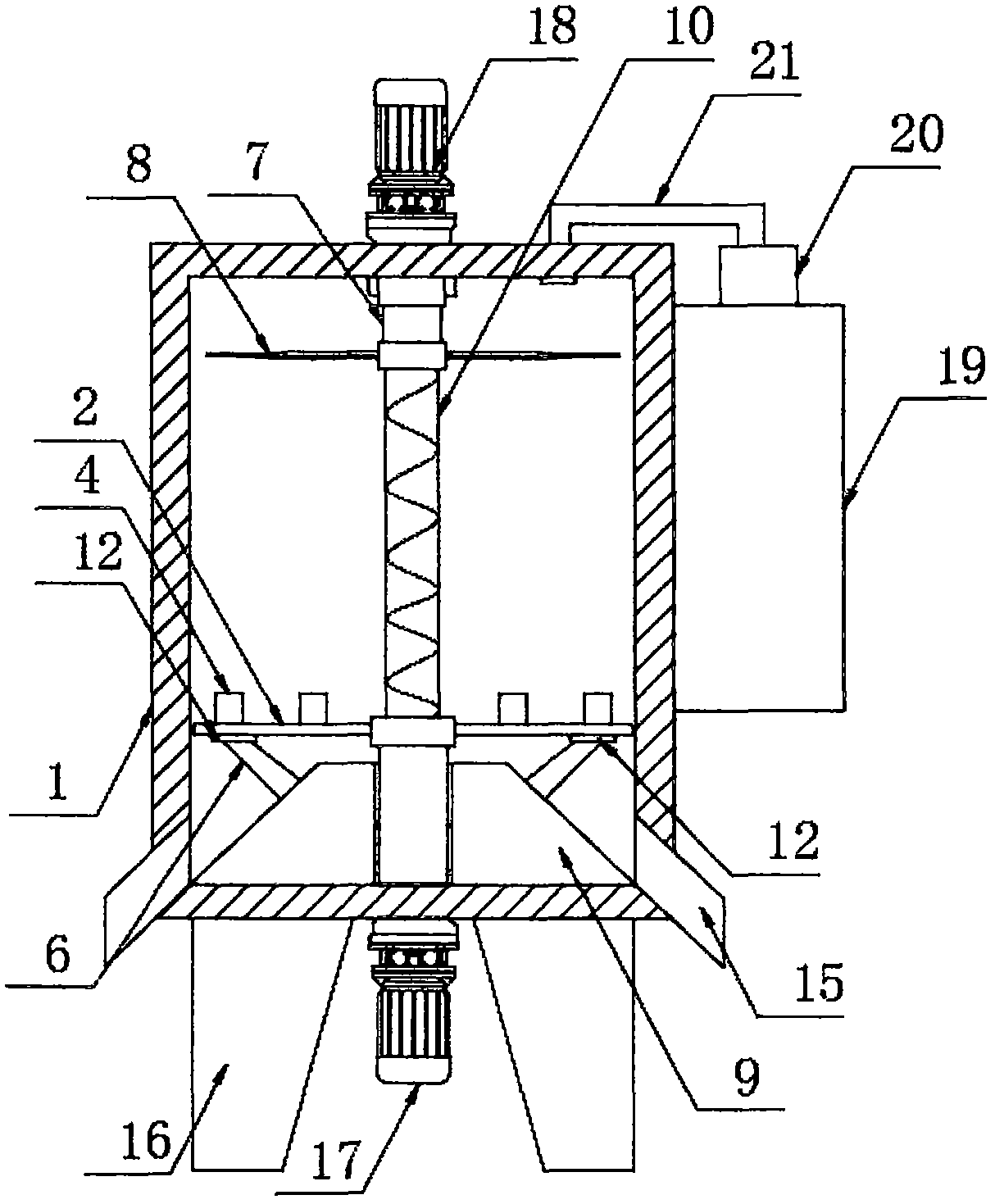

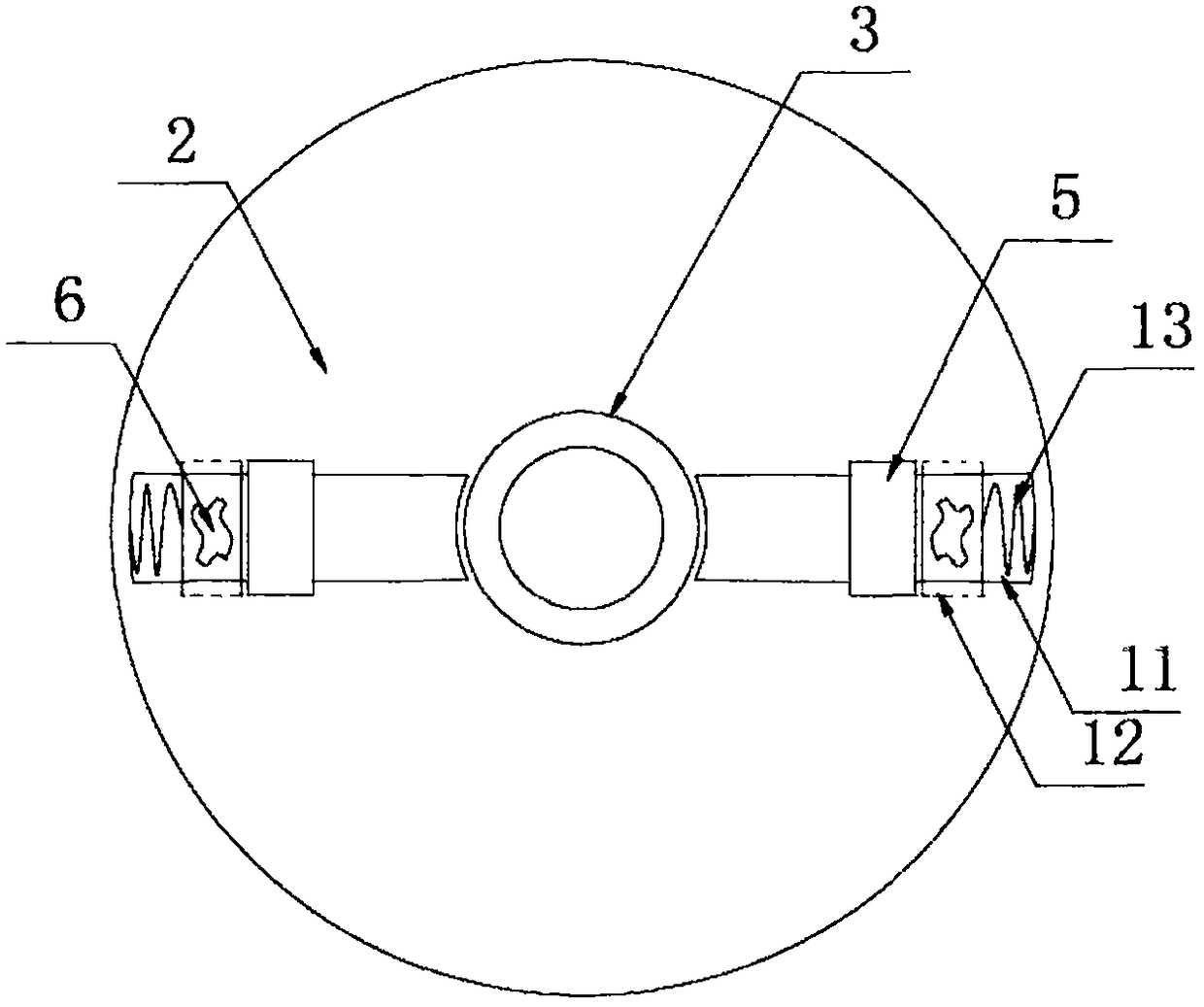

[0028] according to Figure 1-3 A reciprocating extrusion high-efficiency pasture cutting device shown includes a cutting device main body 1, a compression plate 2 is arranged inside the cutting device main body 1, and a connecting shaft 3 is arranged at the bottom end of the compression plate 2, and the connecting shaft 3. The top end runs through the compression plate 2, and extends to one side of the top of the compression plate 2 to be fixedly connected with the compression plate 2. Stirring shafts 4 are fixedly installed on both sides of the top of the compression plate 2, and discharges are arranged on both sides of the top of the compression plate 2. Port 5, the bottom end of the discharge port 5 runs through the compression plate 2, and extends to one side of the bottom end of the compression plate 2, the two sides of the bottom end of the compression plate 2 are provided with brackets 6, and the other end of the bracket 6 is connected to the connecting shaft 3 one sid...

Embodiment 2

[0031] The difference with embodiment 1 is:

[0032] The bottom end of the compression plate 2 is provided with a support column 9, the support column 9 is fixedly arranged at the bottom of the inner cavity of the main body of the cutting device 1, and the support column 9 is arranged in a circular platform, and grooves are arranged on both sides of the top of the support column 9, The bottom end of the groove extends to the inner cavity of the compression plate 2, and the groove and the bracket 6 match each other. The bottom end of the cutting device main body 1 is provided with a threaded rod 10, and the threaded rod 10 runs through the bottom wall of the cutting device main body 1, The support column 9, the connecting shaft 3 and the rotating shaft 7 extend to the top of the rotating shaft 7 and are movably connected with the top wall of the inner cavity of the main body 1 of the cutting device.

[0033] The connecting shaft 3 is threadedly connected with the threaded rod 1...

Embodiment 3

[0040] The difference with embodiment 1 and embodiment 2 is:

[0041] The present invention also provides a method for using a reciprocating extrusion type high-efficiency pasture cutting device, including the following method of use:

[0042] 1) Input the forage grass from the feeding port into the main body 1 of the cutting device. After the forage grass is placed, start the pressurizing pump 20, use the pressurizing pump 20 to pressurize the water stored in the reservoir 19 and pass it through the water spray pipe 21 is transported to the main body of the cutting device 1, and the grass in the main body of the cutting device 1 is cleaned with water pressurized by the water spray pipe 21;

[0043] 2) After the grass is cleaned, let it stand for 1-2 hours to dry the moisture in the grass, and then start the first rotating motor 17, which will drive the threaded rod 10 to rotate when the first rotating motor 17 runs, and the connecting shaft 3 It is threadedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com