A high-speed permanent magnet brushless DC motor control method based on variable conduction period

A permanent magnet brushless DC, motor control technology, applied in motor control, current controller, control system, etc., can solve the increase of motor electromagnetic torque ripple, loss and inverter stress increase, current RMS and peak value Increase and other problems to achieve the effect of reducing rotor eddy current loss, minimizing pulsation, and improving current waveform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

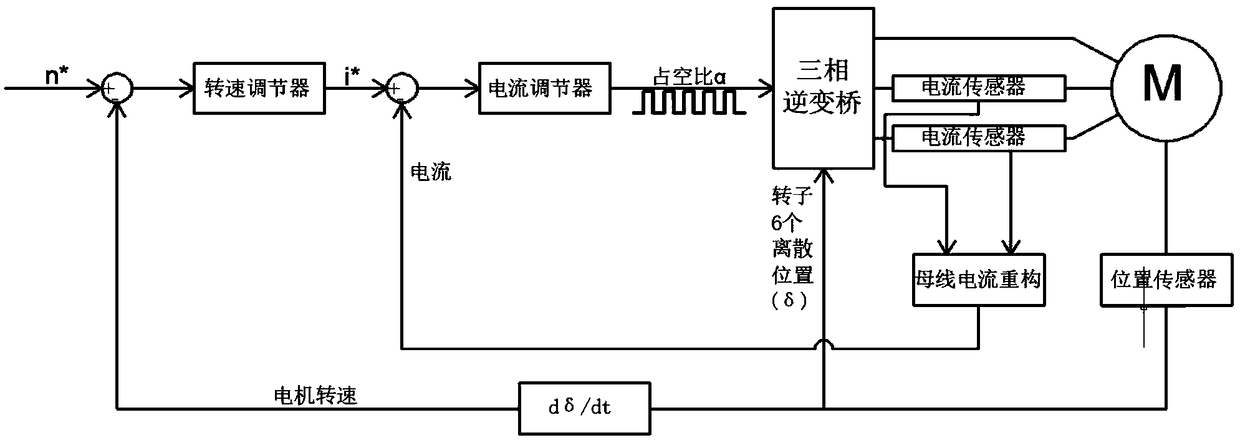

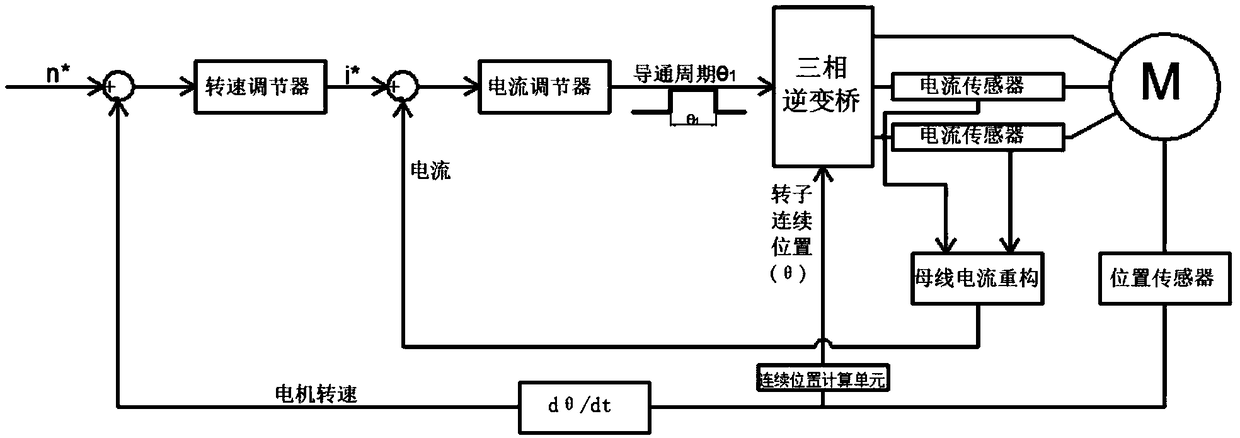

[0044] figure 1 It is a block diagram of a traditional permanent magnet brushless DC motor speed and current double closed-loop PWM control system. The control strategy adopts a three-phase six-state 120° conduction mode, and each state conducts two power switch tubes. The conduction period of each power tube For an electrical angle of 120°, the Hall position sensor of the motor provides the position information required for state switching. According to the principles of electromechanics, in order to realize the speed regulation of the brushless DC motor, the voltage applied to both ends of the motor winding must be changed. The traditional control method is to generate a PWM wave with a fixed chopping cycle and an adjustable duty cycle and the 120° con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com