Auxiliary wiring equipment for electric aerial work

A technology for high-altitude operation and auxiliary wiring, which is applied to the equipment for connecting/terminating cables, etc., which can solve the problems of time-consuming and laborious, insufficient adjustment position accuracy, and danger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the content taught by the present invention, those skilled in the art may make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined in the present application.

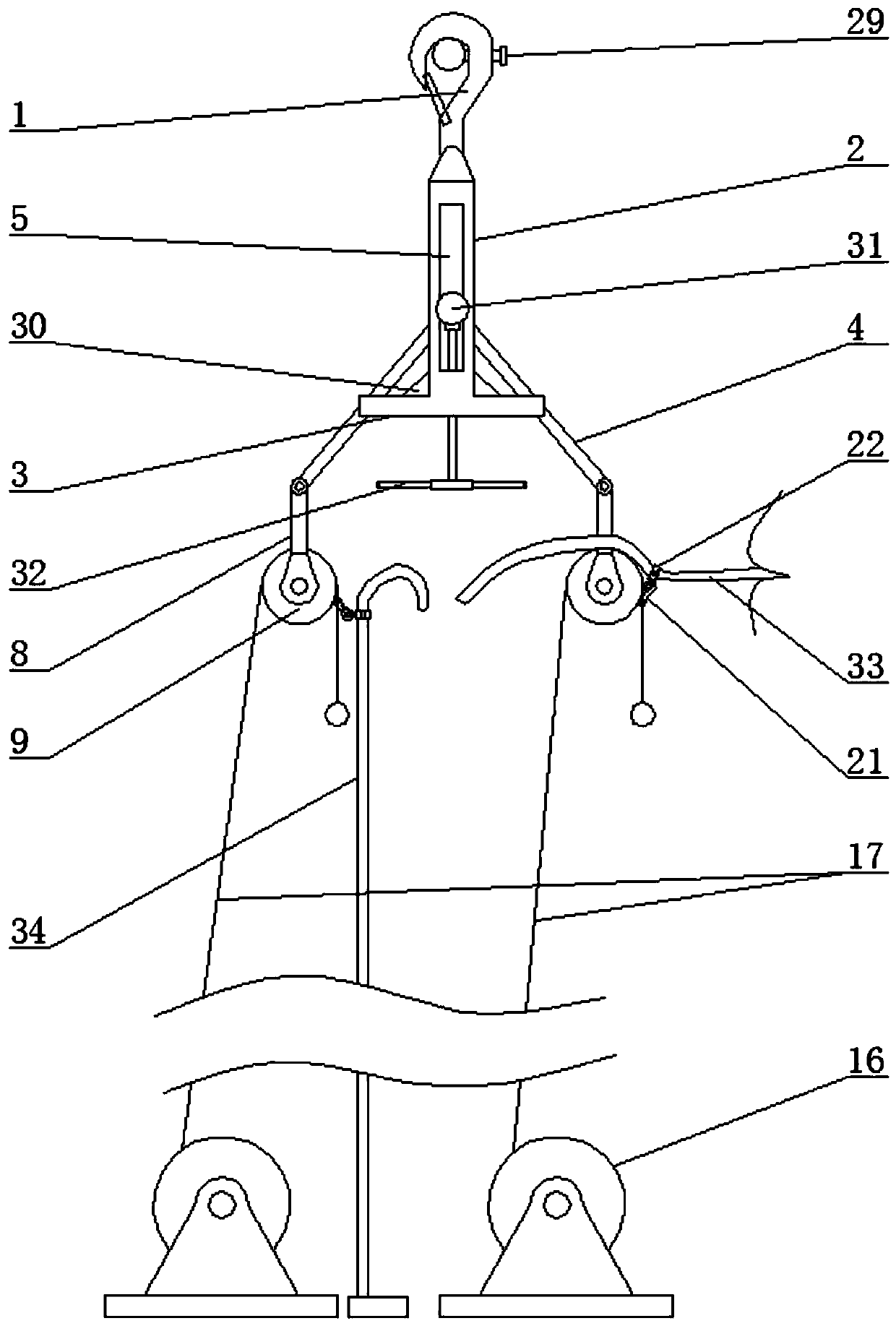

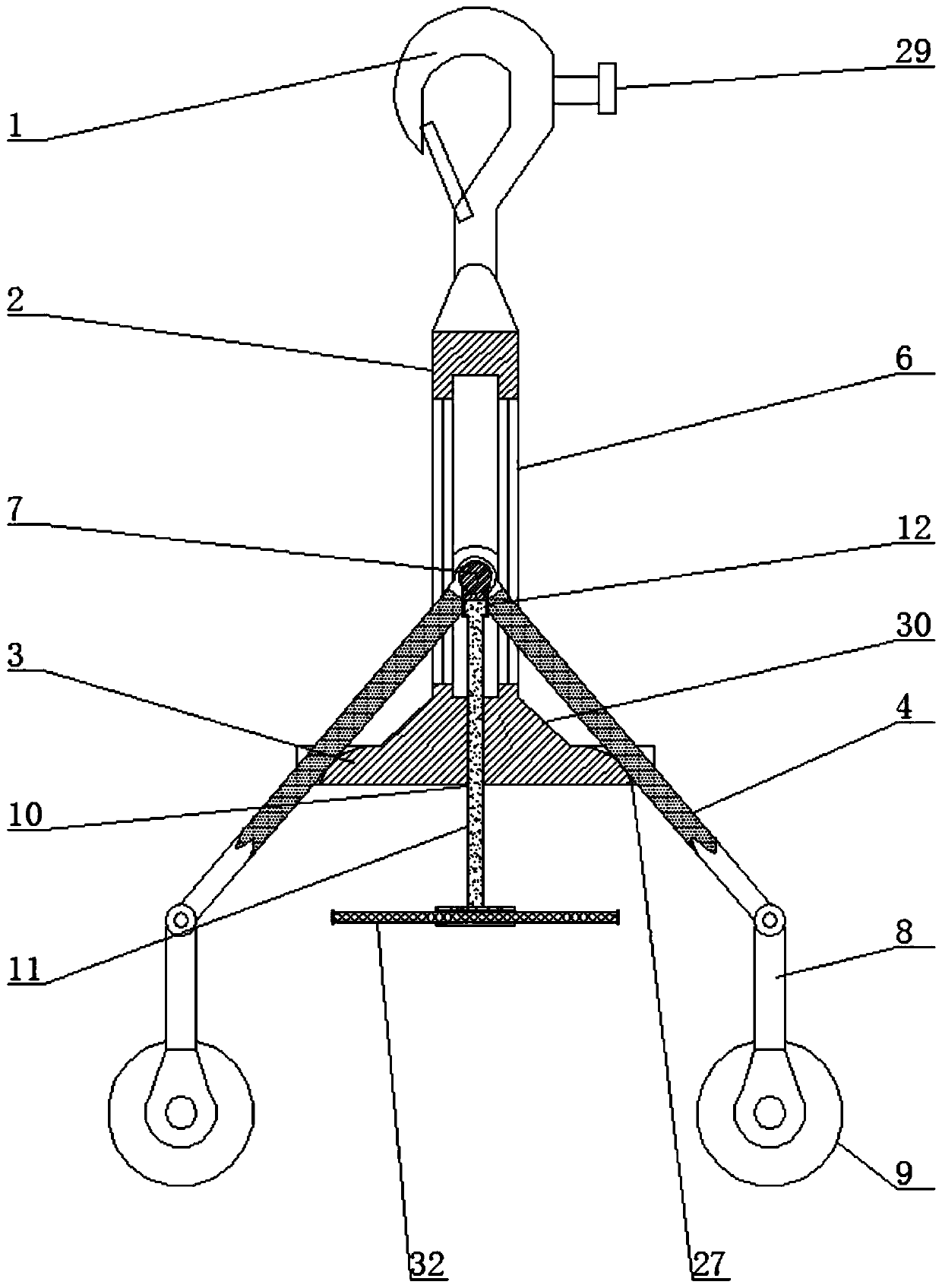

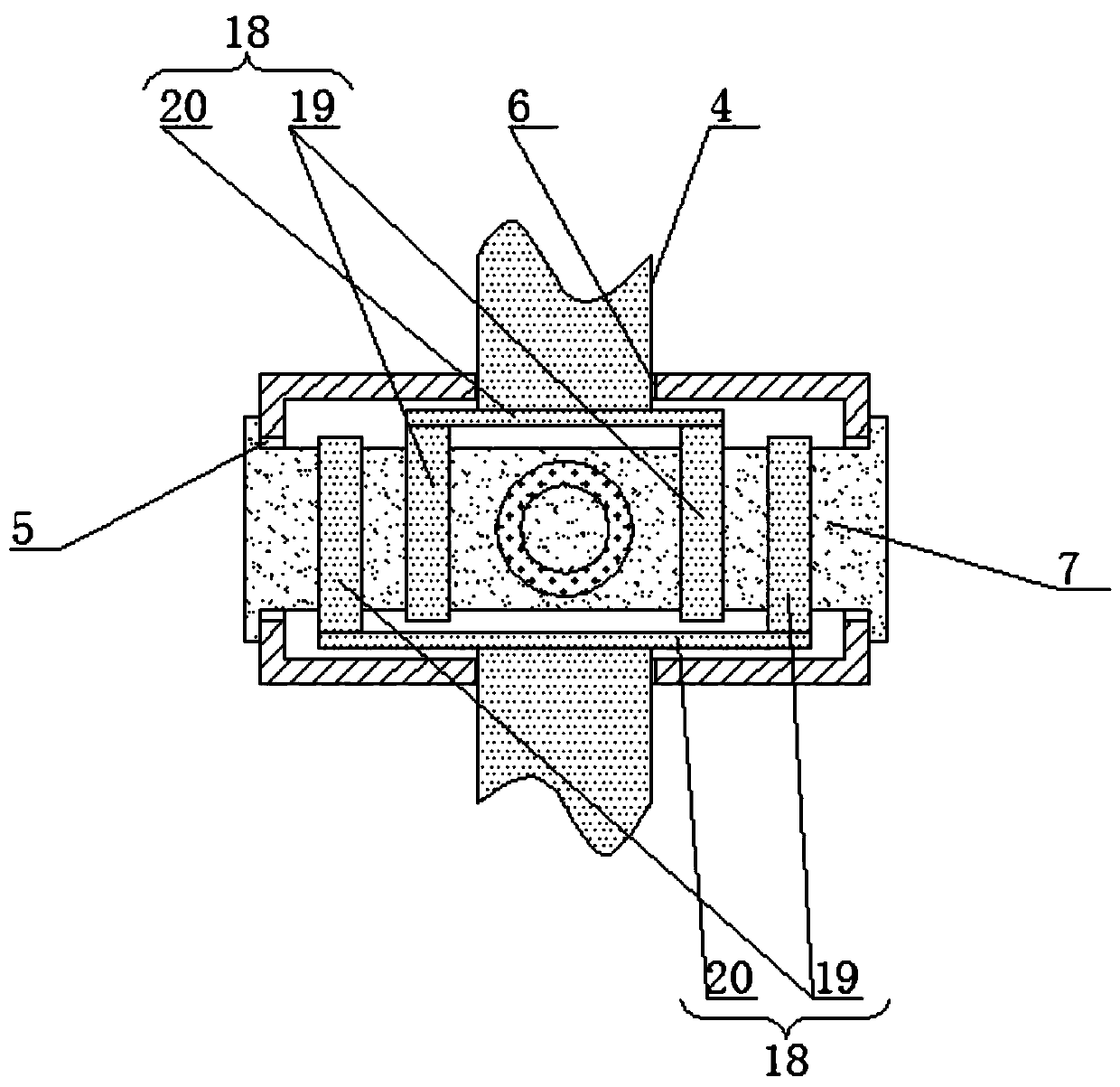

[0036] The present invention is an auxiliary wiring device for electric high-altitude operations. The main structure includes a cross-arm hook 1, a square hollow vertical tube 2, an overlapping projection 3, hinged rods 4 on both sides of the square hollow vertical tube 2, a pulley assembly and Adjusting device assembly, electric winding mechanism;

[0037] The bottom end of the cross arm hook 1 is fixed on the top of the square hollow vertical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com