A waste treatment device for new energy vehicle battery production

A new energy vehicle and waste disposal technology, which is applied in the field of waste disposal devices for battery production of new energy vehicles, can solve the problems of incapable of air-drying waste batteries in time, crushing and processing waste batteries, and inconvenient screening of waste batteries. The effect of crushing efficiency and improving screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

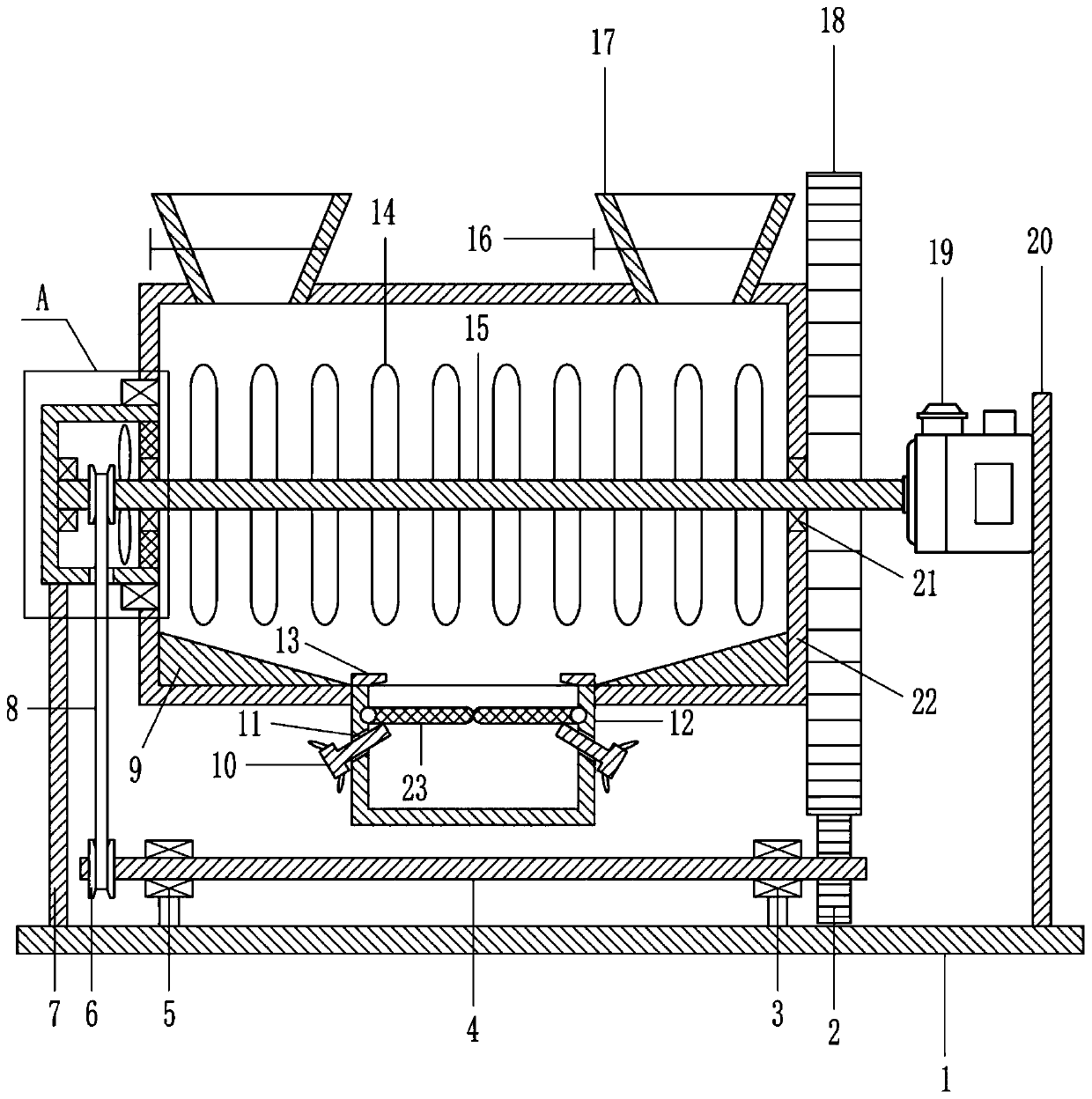

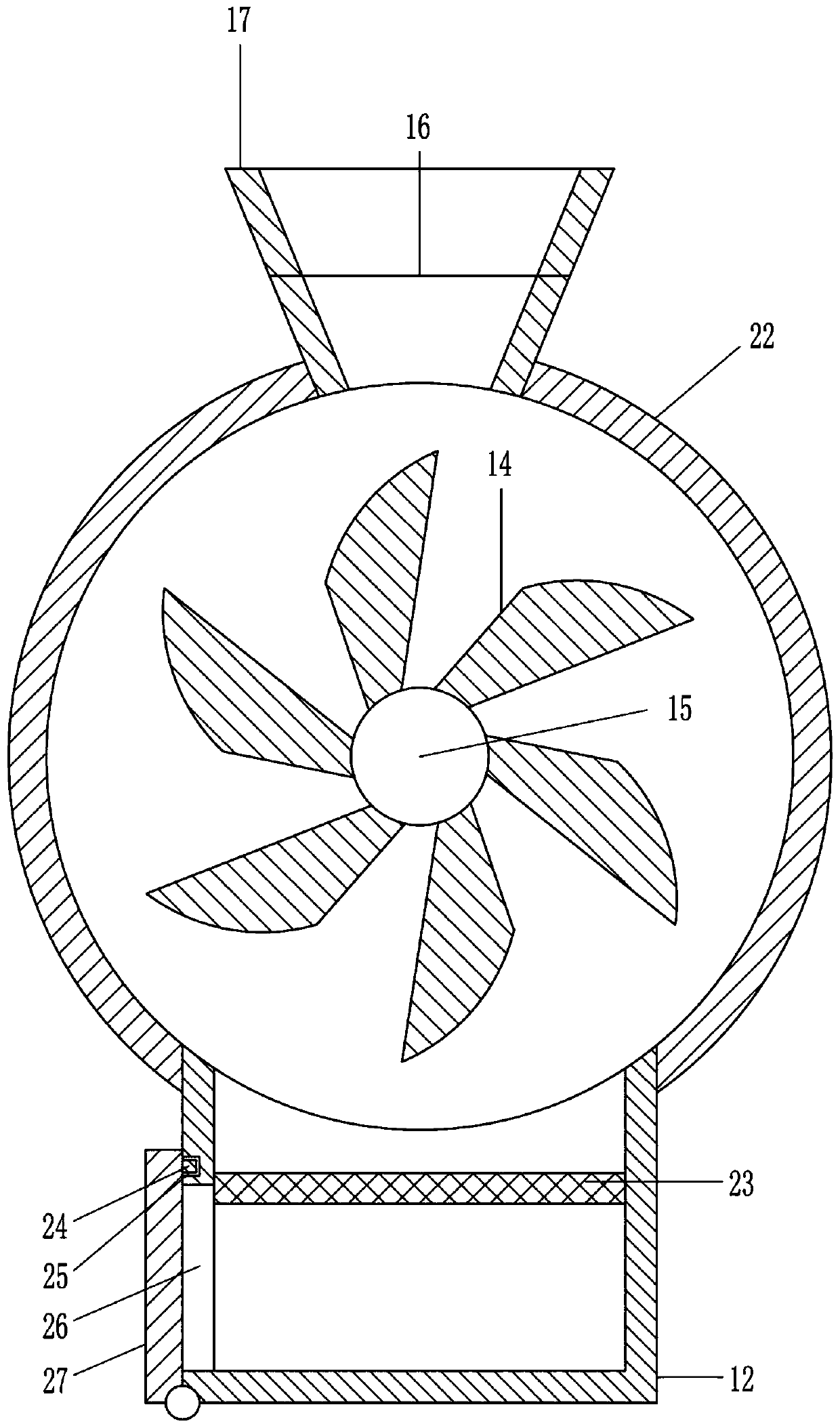

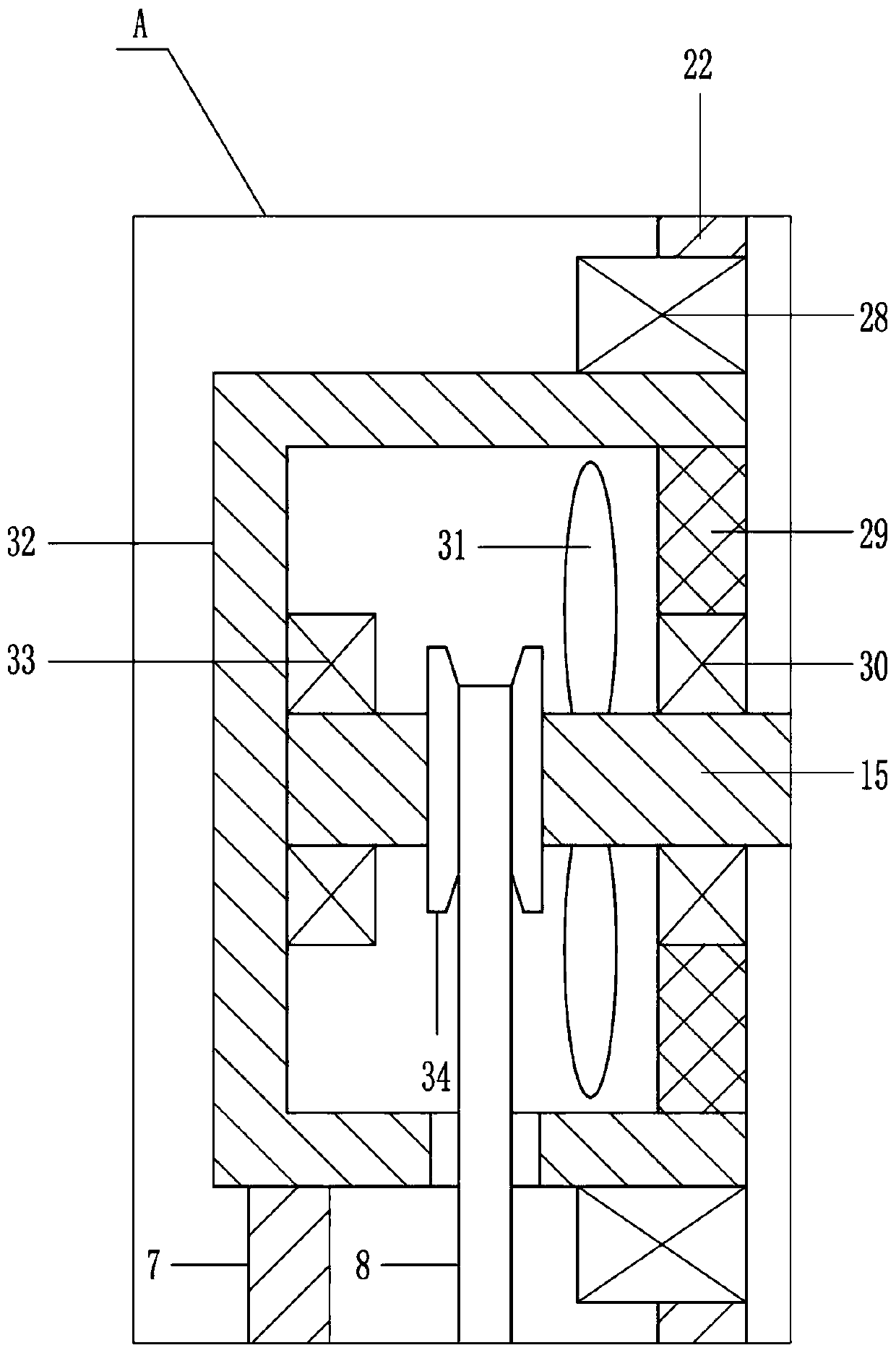

[0033] A waste treatment device for new energy vehicle battery production, such as Figure 1-10As shown, it includes a support plate 1, a first gear 2, a first bearing seat 3, a first rotating shaft 4, a second bearing seat 5, a first transmission wheel 6, a first fixed plate 7, a transmission belt 8, an inclined block 9, Butterfly bolt 10, return material frame 12, debris knife plate 14, second rotating shaft 15, feed valve 16, second gear 18, servo motor 19, second fixing plate 20, third bearing seat 21, debris frame 22. Insert block 24, baffle plate 27, fourth bearing seat 28, breathable mesh plate 29, fifth bearing seat 30, fan blade 31, protection frame 32, sixth bearing seat 33 and second transmission wheel 34; the first fixed The plate 7, the second bearing seat 5, the first bearing seat 3 and the second fixing plate 20 are sequentially fixed on the top of the support plate 1; one end of the first rotating shaft 4 is pivotally connected with the first bearing seat 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com