Continuous preparation method for antibody (or antigen)-coated microspheres

A technology of microspheres and antibodies, which is applied in the preparation of microspheres, microcapsule preparations, measuring devices, etc., can solve the problems of low utilization of antibody antigens, uneven microsphere packaging, and large differences in microspheres. The effect of small size, good effect and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention provides a continuous preparation method of antibody (or antigen) coated microspheres. The specific preparation steps are as follows:

[0026] Step 1: First prepare microspheres, antibody or antigen solution, condensing agent and buffer;

[0027] Step 2: Inject the microspheres in the microsphere tank 3 and the condensing agent in the condensing agent tank 4 into the first tank 1 through the first pressure pump and pipeline for mixing, and the antibody or antigen solution in the antibody or antigen solution tank 5 The buffer solution in the buffer solution tank 6 is injected into the second tank body 2 through the first pressure pump and the pipeline for mixing;

[0028] Step 3: The first tank body 1 and the second tank body 2 are equipped with a first air inlet pipe 7, which is operated by a fan 17, and the gas is blown into the gas distribution pipe 13 through the main inlet pipe 16 and heated by the heating layer 14, and then passes through the first ...

Embodiment 2

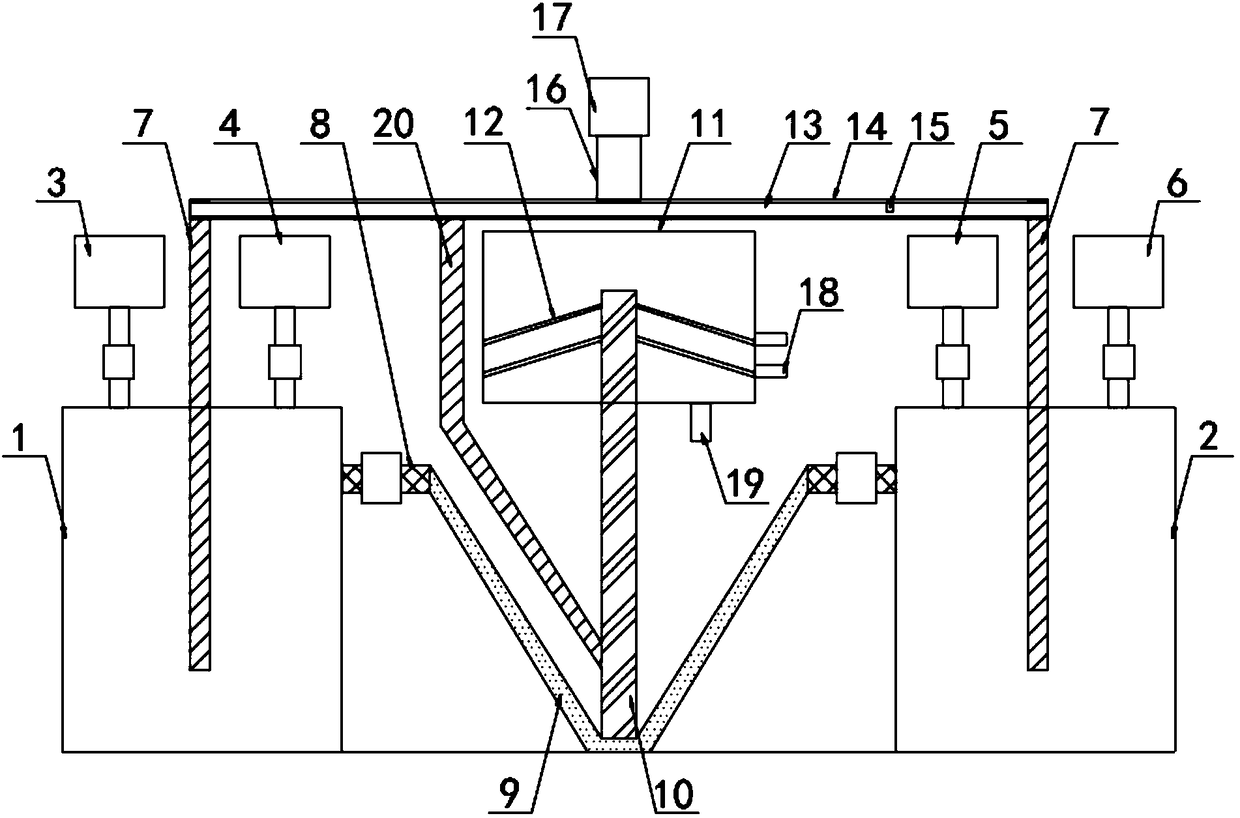

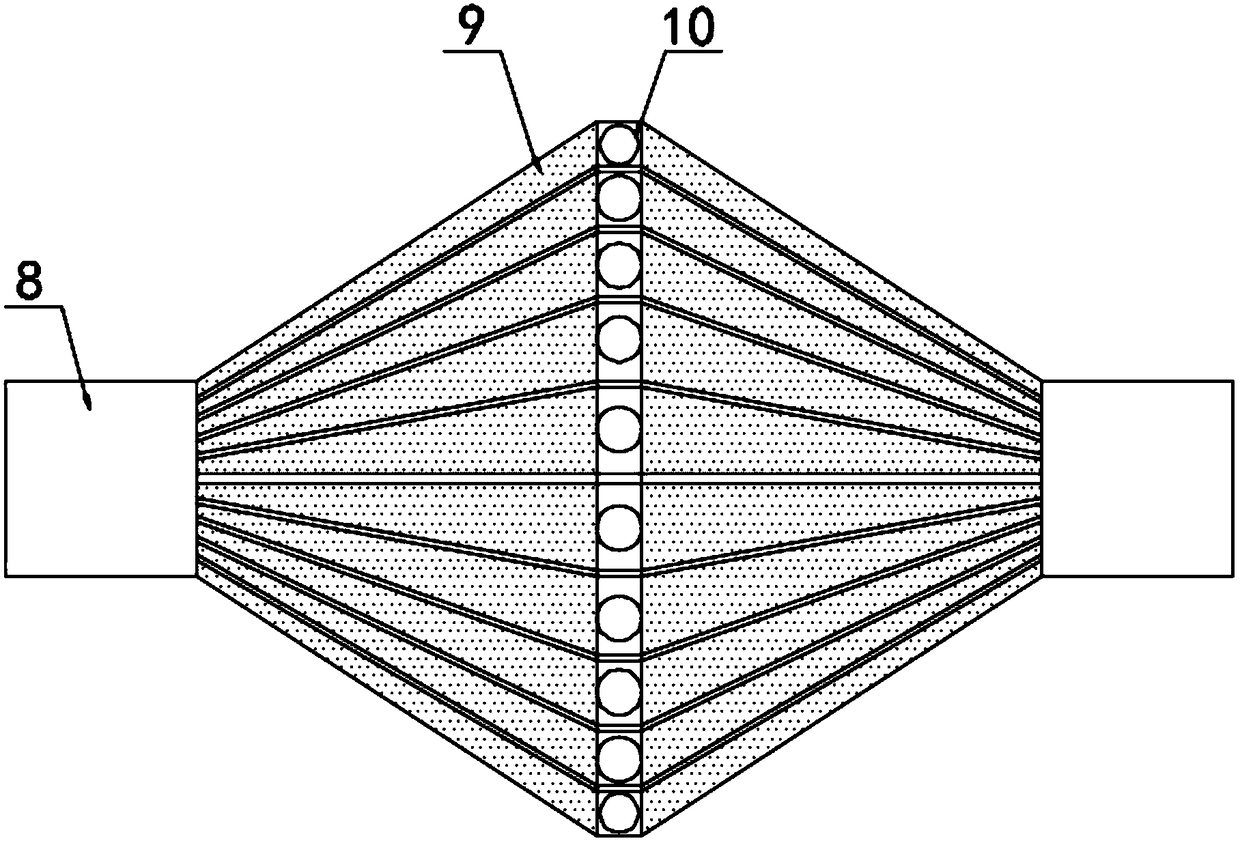

[0034] The present invention also provides figure 1 A continuous preparation device for antibody (or antigen) coated microspheres is shown. The top of the first tank 1 is connected with a microsphere tank 3 and a condensing agent tank 4 through a pipeline, and a pressure pump is provided on the pipeline , The top of the second tank 2 is connected with an antibody or antigen solution tank 5 and a buffer tank 6 through a pipe, and the first tank 1 and the second tank 2 are both provided with a first air inlet pipe 7, The inner side of the first tank body 1 and the second tank body 2 is provided with a header pipe 8, the header pipe 8 is provided with a second pressure pump, the end of the header pipe 8 is fixedly provided with a shunt pipe 9, and the bottom of the shunt pipe 9 There is a collecting branch 10, the top of the collecting branch 10 is provided with a filter tank 11, and a filter membrane 12 is provided inside the filter tank 11.

[0035] Further, in the above technical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com