Visualized experimental device for CHF research in bidirectionally visible rectangular narrow channel

An experimental device and narrow channel technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of different gaps in rectangular flow channels, the inability to observe the growth of bubbles from the side, and the inability to ensure the same degree of screwing of bolts, etc., to achieve changing flow The effect of reducing the road gap, avoiding expansion and deformation, and reducing the thickness of the narrow surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

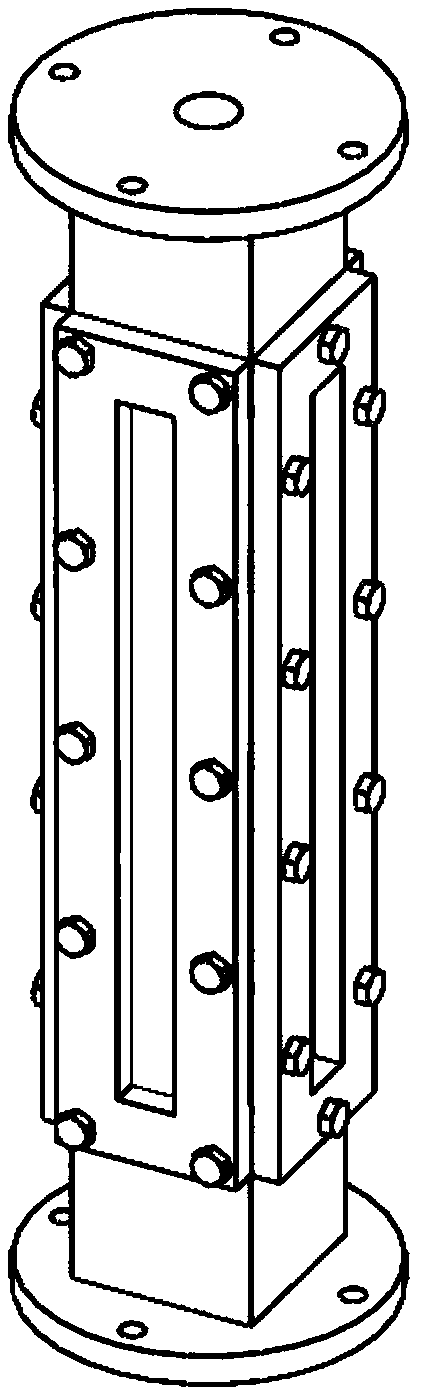

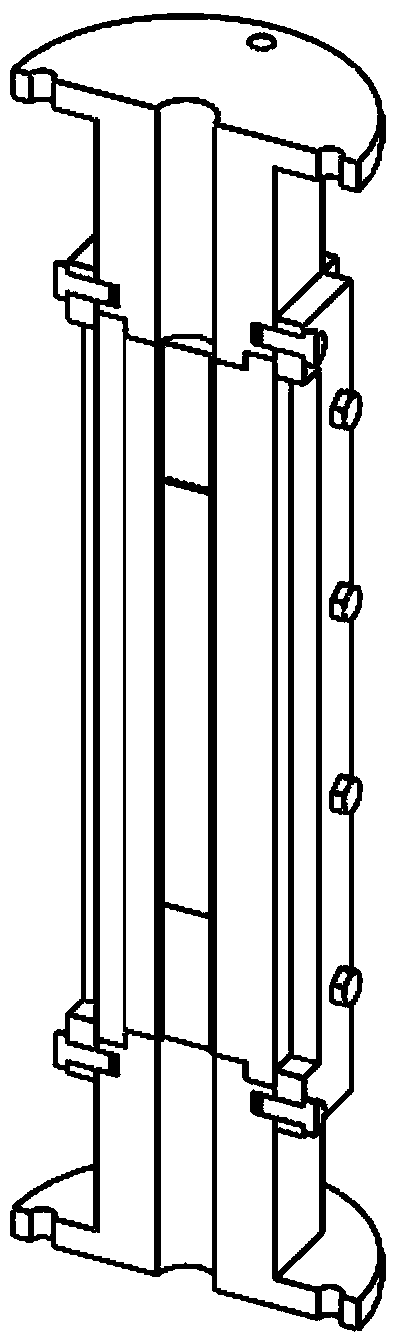

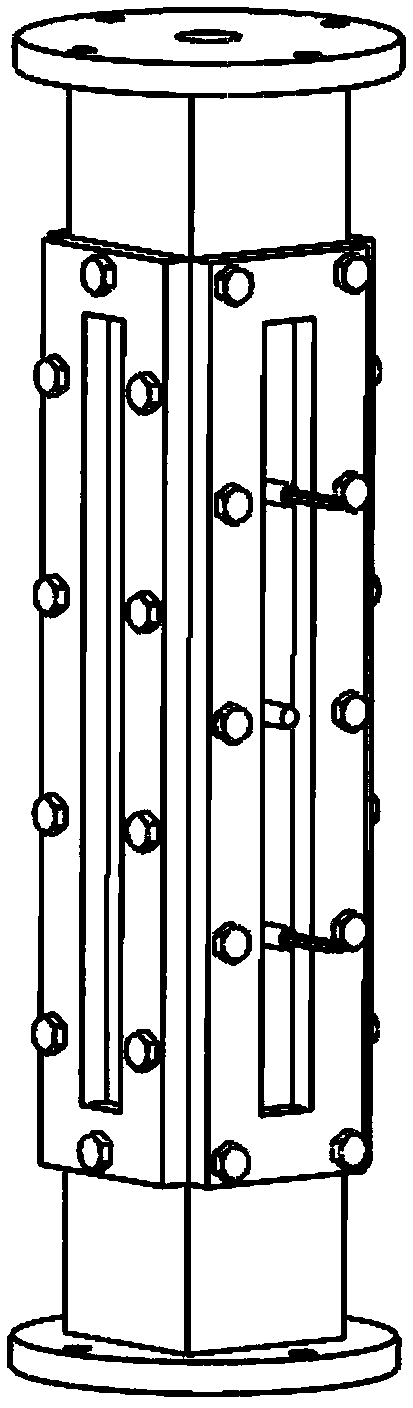

[0022] The main purpose of the present invention is to provide a two-way visual CHF research visualization experiment device in a narrow rectangular channel. The device mainly includes a heating plate, a substrate, a wide side quartz glass, a narrow side quartz glass, a shell, a pressure bearing plate, a gasket for sealing and a bolt for connection. The fluid flows into the narrow rectangular channel from the lower flange hole, and is heated and boiled by the heating plate to form a two-phase mixture and flows out from the upper flange hole. Compared with the traditional rectangular channel visualization device, the visualization device adopted in the present invention can not only observe the evolution of the flow pattern and the behavior of the bubbles from the front, but also observe the generation, growth, aggregation and detachme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com