Industrial CT detection system

A detection system and industrial technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of low utilization rate and inconvenient movement of industrial CT, and achieve the effect of improving utilization rate, reducing mobile costs, and improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

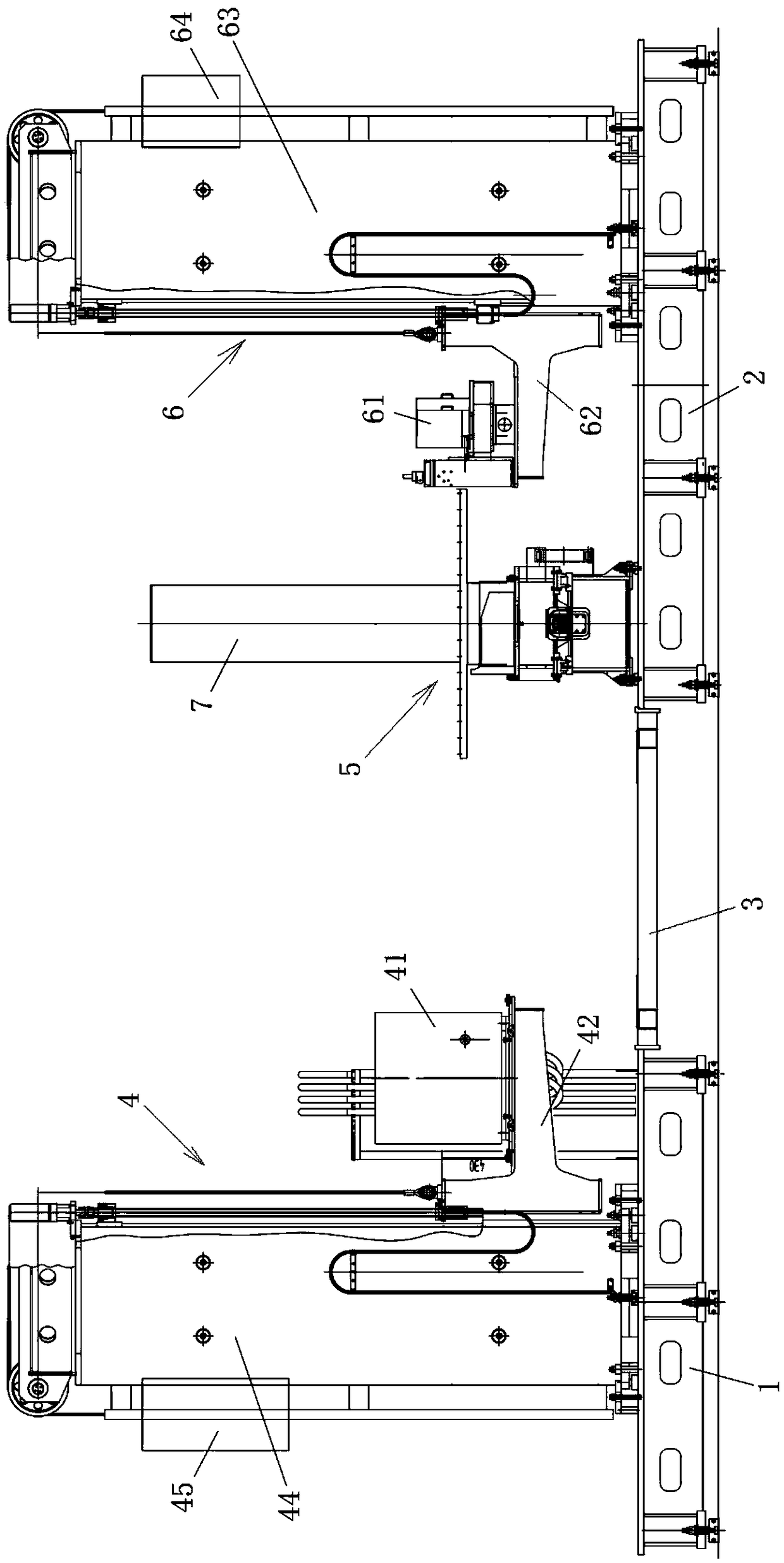

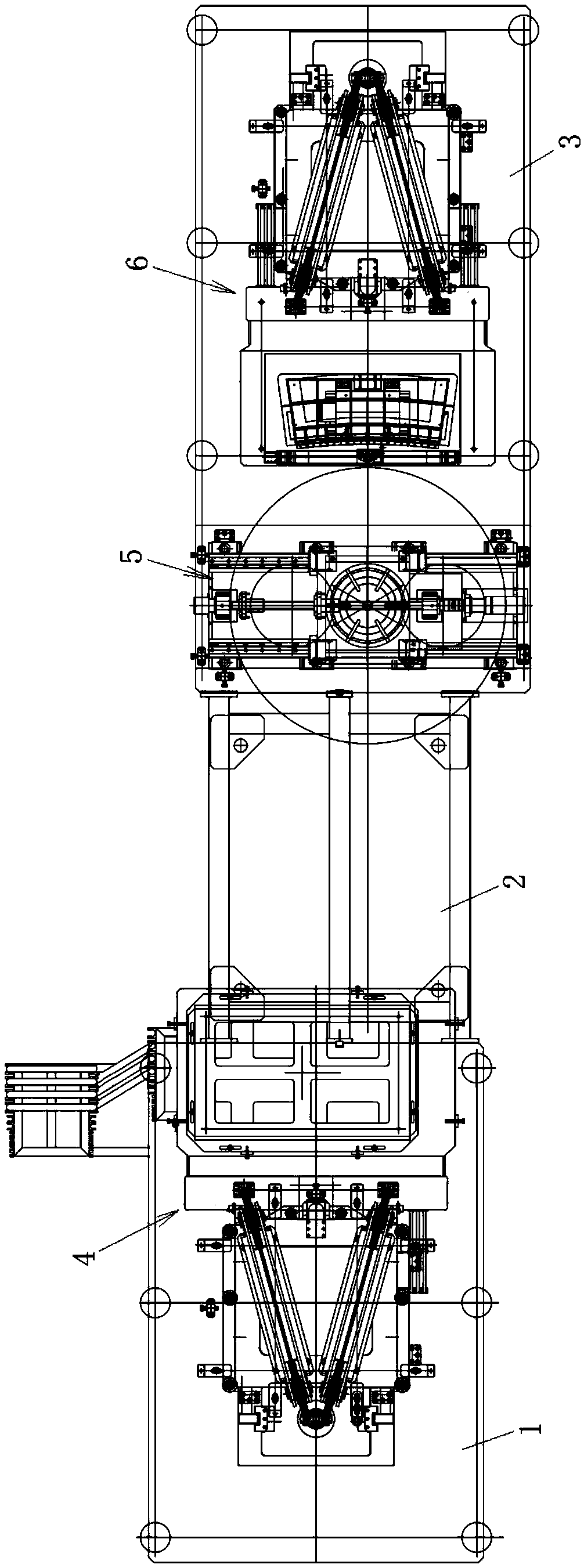

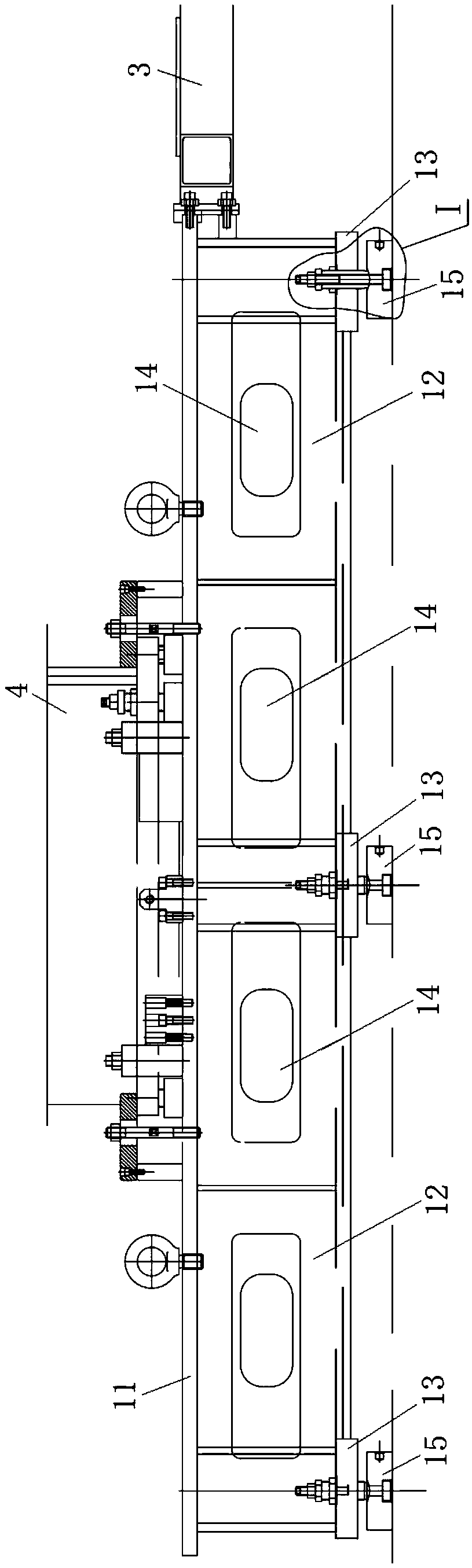

[0032] Such as figure 1 with figure 2 As shown, the industrial CT detection system includes a first installation platform 1, a second installation platform 2, a platform connection frame 3, a radiation source 4, a turntable 5 and a detector unit 6, and the first installation platform 1 and the second installation platform 2 are fixedly connected At two opposite ends of the platform connecting frame 3, and make the upper surfaces of the first installation platform 1 and the second installation platform 2 be in the same plane. The radiation source 4 is fixed on the upper surface of the first installation platform 1 , and the turntable 5 and the detector unit 6 are fixed on the upper surface of the second installation platform 2 . In other words, the platform connection frame 3 fixedly connects the first installation platform 1 and the second installation platform 2 together, so that the first installation platform 1 and the second installation platform 2 are integrated, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com