Strength testing device for connector of aerostat

A technology of strength test and connecting parts, which is applied in the field of aerostat test, can solve the problems of low installation efficiency, large space occupation, and long test cycle, etc., and achieve the effect of fast installation, easy operation, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] During the test, the test piece is fixed and tensioned by the test fixing module, and the test piece is loaded by the test loading module. The entire test device is a self-balancing structure and does not require additional constraints.

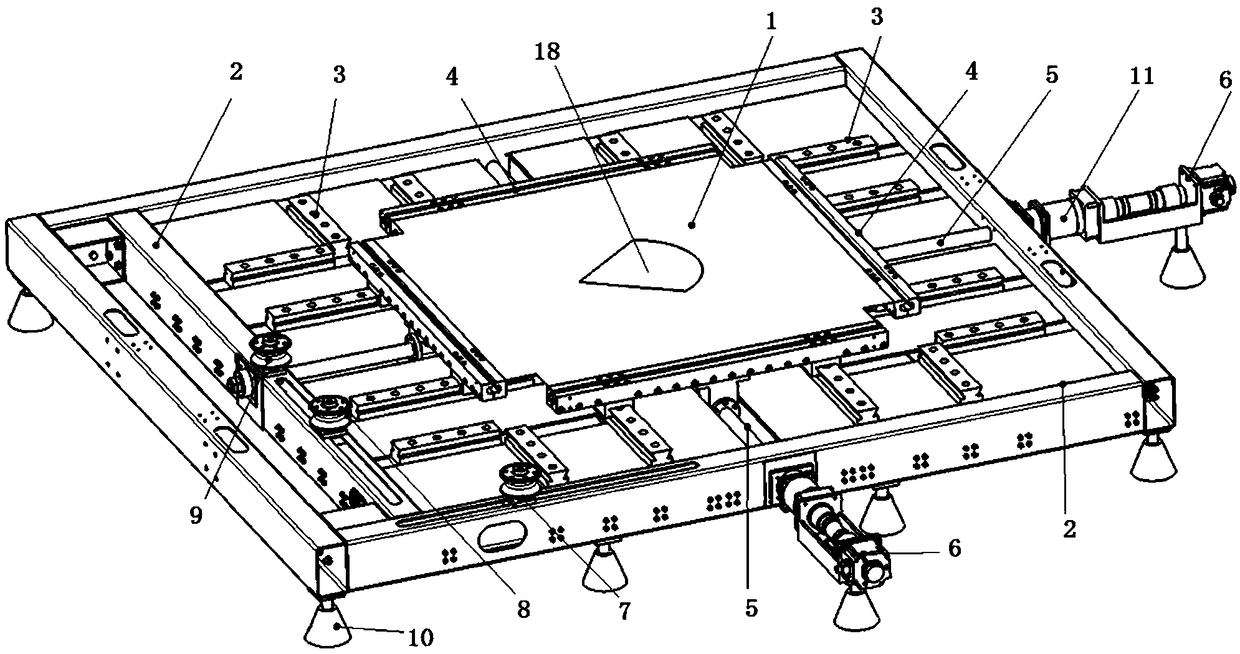

[0025] A strength test device for aerostat connectors, used to perform a separation strength test on a connector formed by thermal welding of the base cloth 1 and the connecting cloth 18. The device includes a fixed module at the bottom and a loading module at the upper part.

[0026] The fixed module tightens and fixes the edge of the base fabric 1 on the fixed stand 2; horizontal loading pulleys are also provided at different positions on the edge of the fixed stand 2;

[0027] The loading module fixes the pulley guide rail 13 above the fixed bench 2 through the loading platform 12, and a movable vertical loading pulley is installed on the pulley guide rail 13. The loading module also has an actuator 14 with one end of the cable connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com