Boiler combustion optimization method based on adaptive neuro-fuzzy PID control

A neuro-fuzzy, boiler combustion technology, applied in the control of combustion, lighting and heating equipment, etc., can solve the problems of fuzzy PID control membership, strong dependence, PID control parameters cannot be self-tuning, etc., to achieve good robustness, control Precise, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

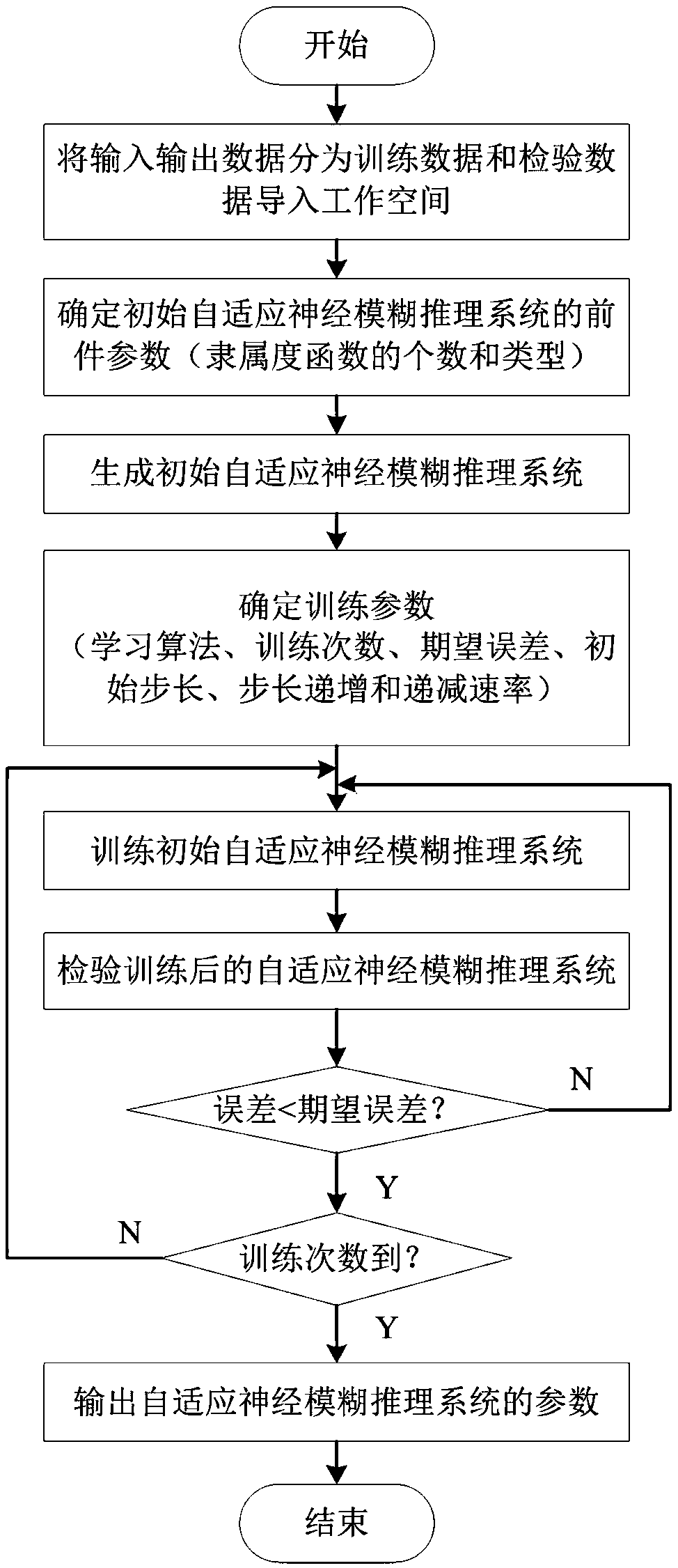

[0024] The present invention is a boiler combustion optimization method based on adaptive neuro-fuzzy PID control, and its control system structure schematic diagram is as follows figure 1 shown. The adaptive neuro-fuzzy reasoning system is partly composed of adaptive neuro-fuzzy reasoning system 1, adaptive neuro-fuzzy reasoning system 2 and adaptive neuro-fuzzy reasoning system 3, all of which have double-input and single-output structures. The deviation e and deviation change ec of the furnace temperature are used as the input of the adaptive neuro-fuzzy inference system, and the output of the adaptive neuro-fuzzy inference system is the variation of the parameters of the PID controller ΔK p , ΔK i and ΔK d , with the initial parameter K of the PID controller p0 、K i0 and K d0 Corresponding summation as parameters of an adaptive neuro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com