Energy-conservation coal-fired furnace

A technology of coal-fired furnace and coal slag, which is applied in lighting and heating equipment, etc., can solve the problem of waste heat not being able to recover and utilize energy consumption, etc., so as to protect the working environment and personnel health, improve the efficiency of energy recovery, and increase the effect of heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

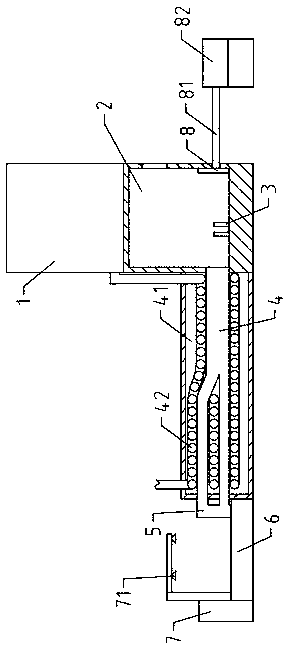

[0019] The specific embodiment of the energy-saving coal-fired furnace of the present invention is as figure 1 As shown, an energy-saving coal-fired furnace includes a combustion chamber 2, an air blast channel 3 and a medium pot 1, the medium pot 1 is arranged directly above the combustion chamber 2, and the three air blast channels communicate with the lower part of the combustion chamber 2. A heat exchange chamber 41 is provided at the lower part of the rear end of the chamber 2, and a cinder storage box 6 is provided at the rear of the heat exchange chamber 41. The heat exchange chamber 41 includes a heat exchange chamber and a cinder channel 4 pierced in the heat exchange chamber. , one end of the cinder channel 4 is connected to the combustion chamber 2, and the other end is connected to the cinder storage box 6. The cinder channel 4 is in the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com