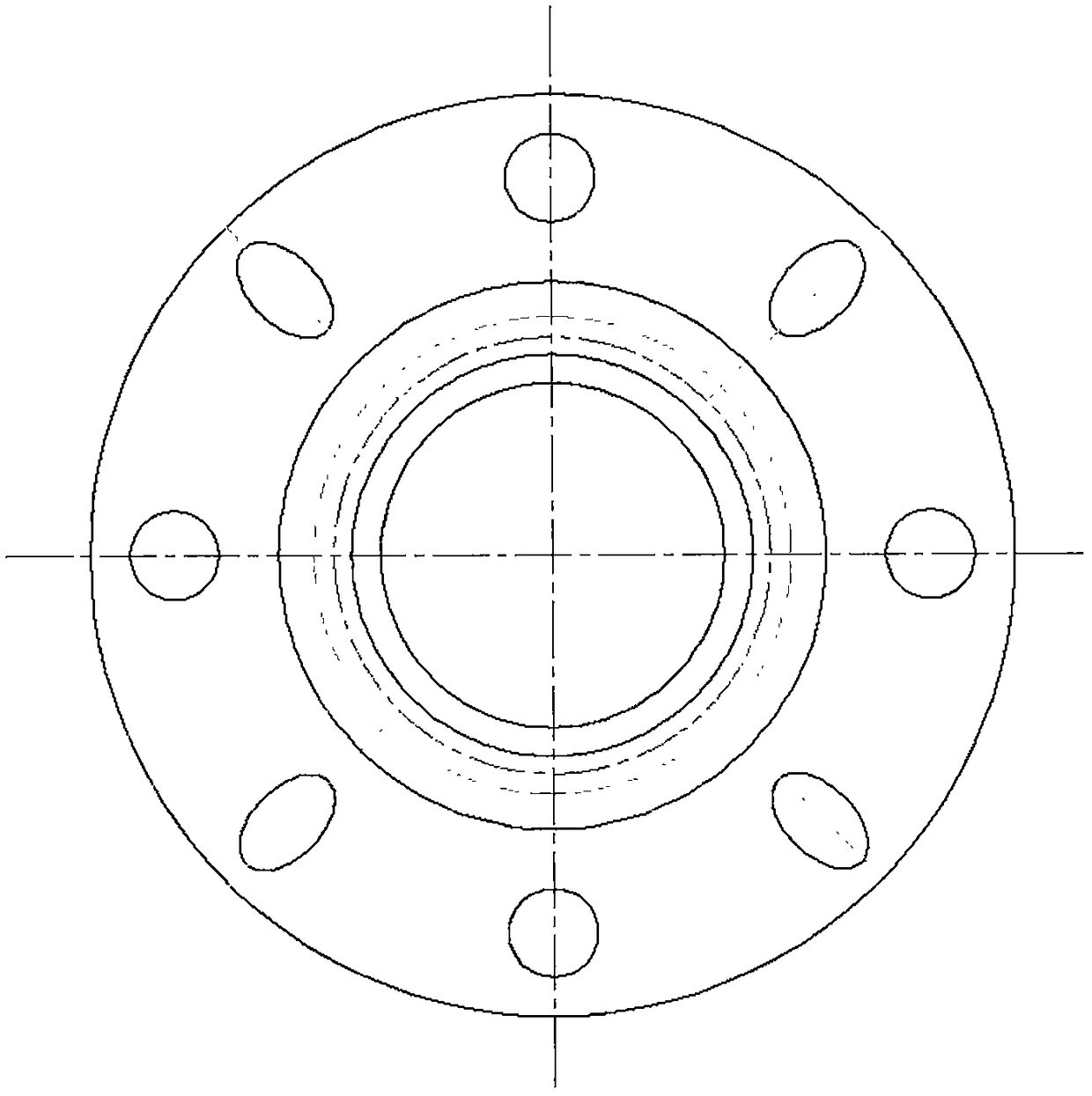

Compression-resisting flange easily achieving alignment

A flange and flange technology, applied in flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve problems such as unfavorable equipment lightweight, flange sealing surface leakage, poor sealing effect, etc. Easy, fast and accurate centering, increased stiffness, lightweight sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings. As shown in the accompanying drawings, the present invention provides an easy-to-center pressure-resistant flange. The large end of the conical shell 5 is welded to the flange, and the small end is a straight edge section and the connected pipeline adopts a butt welding connection type; the flange is welded. 2. The oval bosses 1 are evenly distributed at the ends, and the ends of the flanges that appear in pairs are open with oval grooves; the ends of the flange 2 are evenly distributed with bolt holes 4, and the bolt holes 4 are connected to the oval boss (groove) 1. The spaced arrangement and the number of arrangements can be determined according to the pipeline pressure; the reinforcing rib 3 is welded and connected between the conical shell 5 and the flange plate 2, which effectively improves the rigidity of the flange plate. When the flanges act in pairs, an annular g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com