Mechanical sealing device for high-viscosity ball mill

A mechanical sealing device and ball mill technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems that affect the performance and effect of friction and sealing, and are difficult to apply, so as to achieve the effect of improving reliability and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

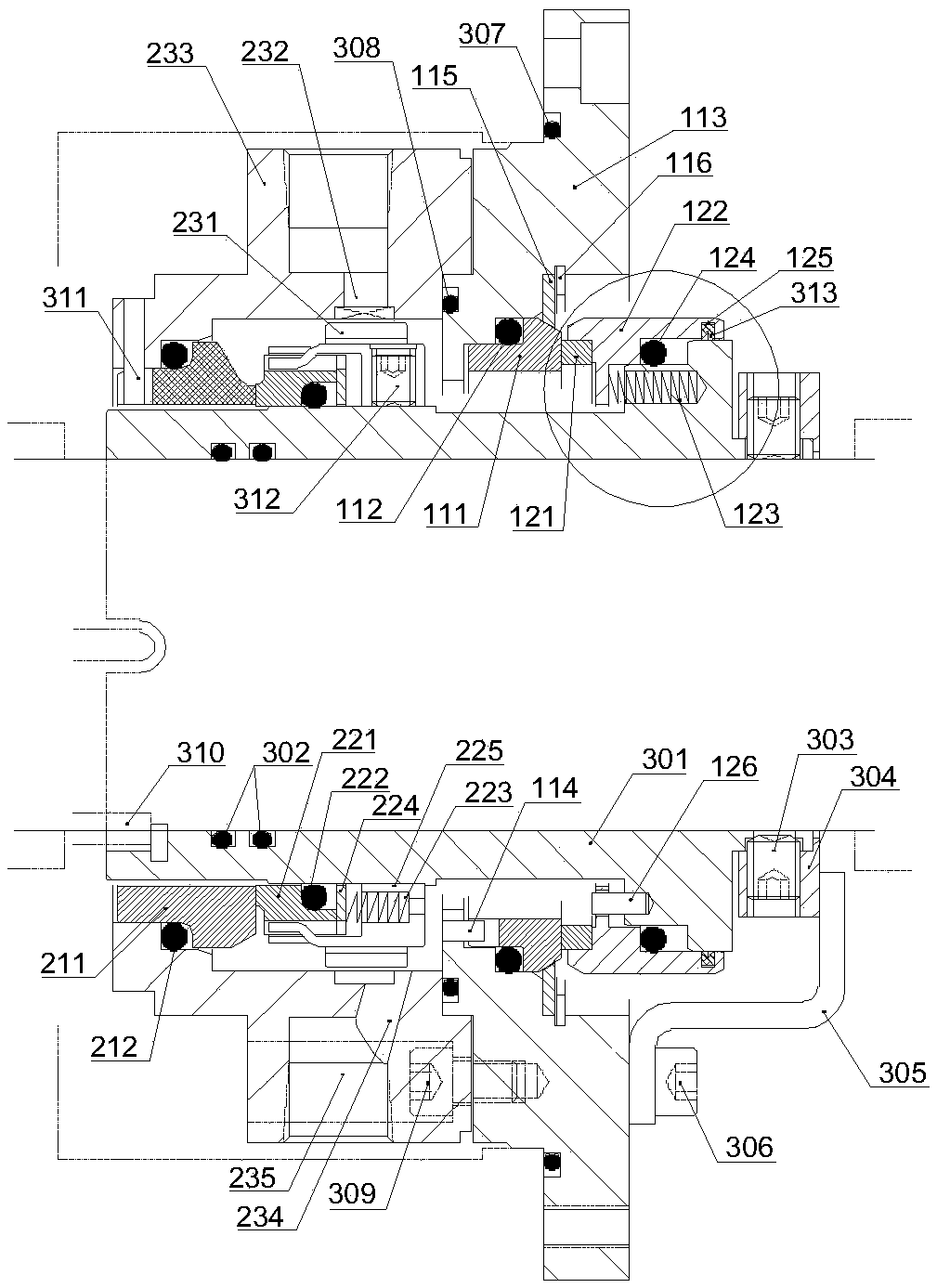

[0028] This embodiment provides a mechanical seal device for a high-viscosity ball mill, such as Figure 1-2 As shown, it includes a shaft sleeve 301, a main seal assembly, and a spacer fluid pumping assembly.

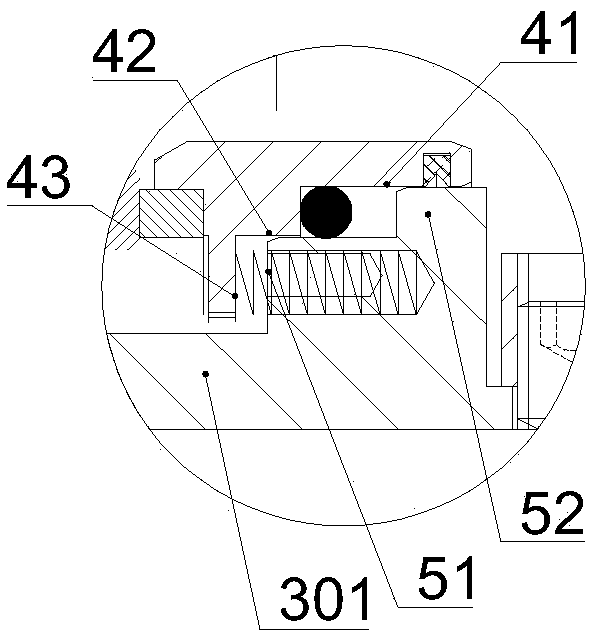

[0029] The shaft sleeve 301 is sheathed on the rotating shaft. The front end of the shaft sleeve 301 is provided with a first stepped boss, and the side of the first step 51 of the first stepped boss is provided with a round hole (not shown in the figure). In order to set the shaft sleeve 301 fixedly on the rotating shaft, the front end of the shaft sleeve 301 is fixed on the rotating shaft through a number of radial clamping screws 303, at least two of which are surface contact screws. Type screw, the shaft sleeve 301 is more tightly hugged to the rotating shaft, and the fixation is more stable. The front end of the shaft sleeve 301 is provided with a driving ring 304, and the driving ring 304 determines reliable axial positioning by tightening the screw 303 to reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com