Tundish carrying table for pouring line

A technology of tundish and pouring line, which is applied in the direction of casting molten material container, metal processing equipment, casting equipment, etc. It can solve the problems of equipment interference accidents, equipment damage, etc., and achieve the effect of high reliability and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

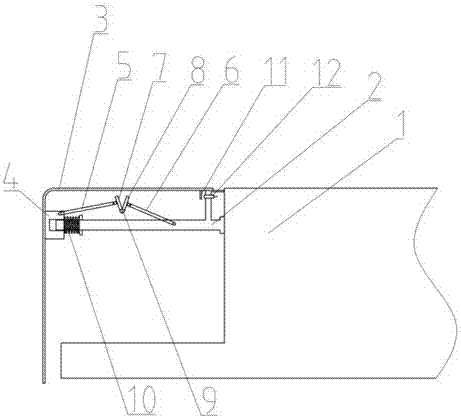

[0015] Exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. Although exemplary embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure may be embodied in various forms and should not be limited by the embodiments set forth herein. Rather, these embodiments are provided for more thorough understanding of the present disclosure and to fully convey the scope of the present disclosure to those skilled in the art.

[0016] According to an embodiment of the present invention, a tundish carrier for a pouring line is proposed. The tundish carrier is a carrier that advances and works with the same running track in a pouring line that adopts a multi-row fixed-position melting furnace. In this pouring line, multiple tundishes enter the melting zone successively along the same track according to the set time and speed. Each tundish is carried by an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com