Bearing with graphite copper sleeve, articulated frame and sweeper

A articulated, copper sleeve technology, applied to the rigid support of bearing components, bearing elements, shafts and bearings, etc., can solve problems such as inconvenient steering, complex bearing structure, difficult maintenance, etc., to achieve reduced friction, simple bearing structure and high efficiency The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

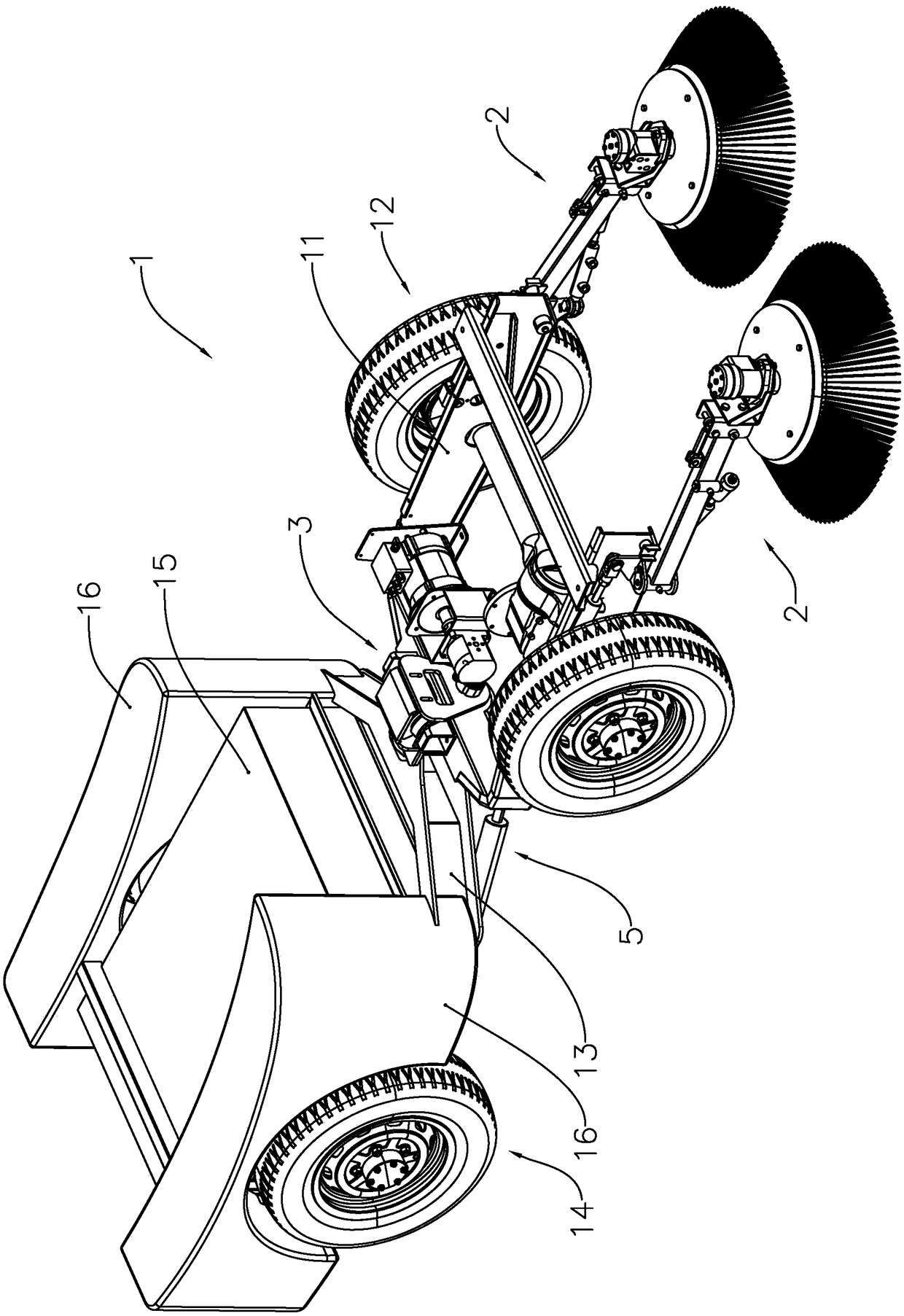

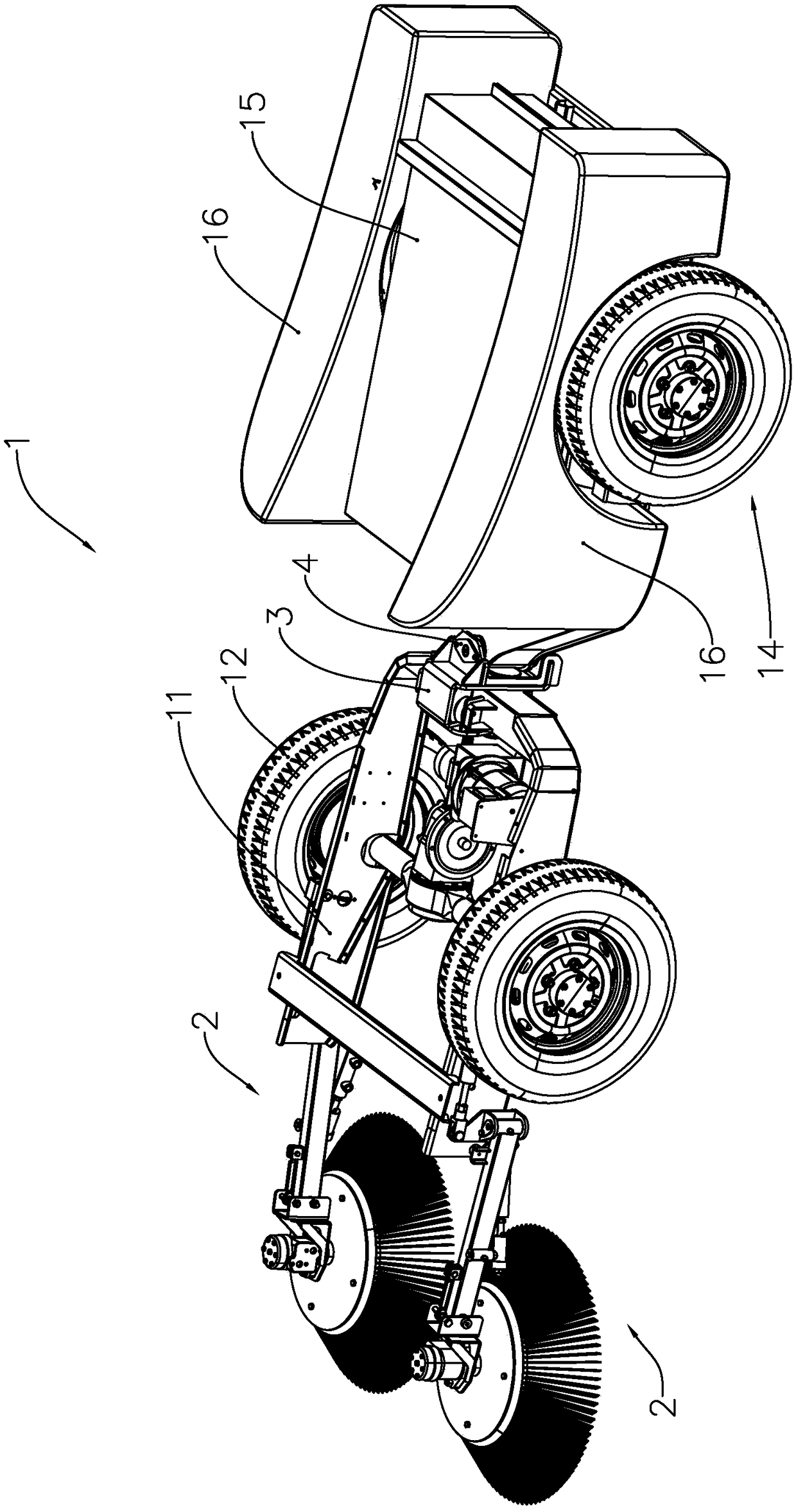

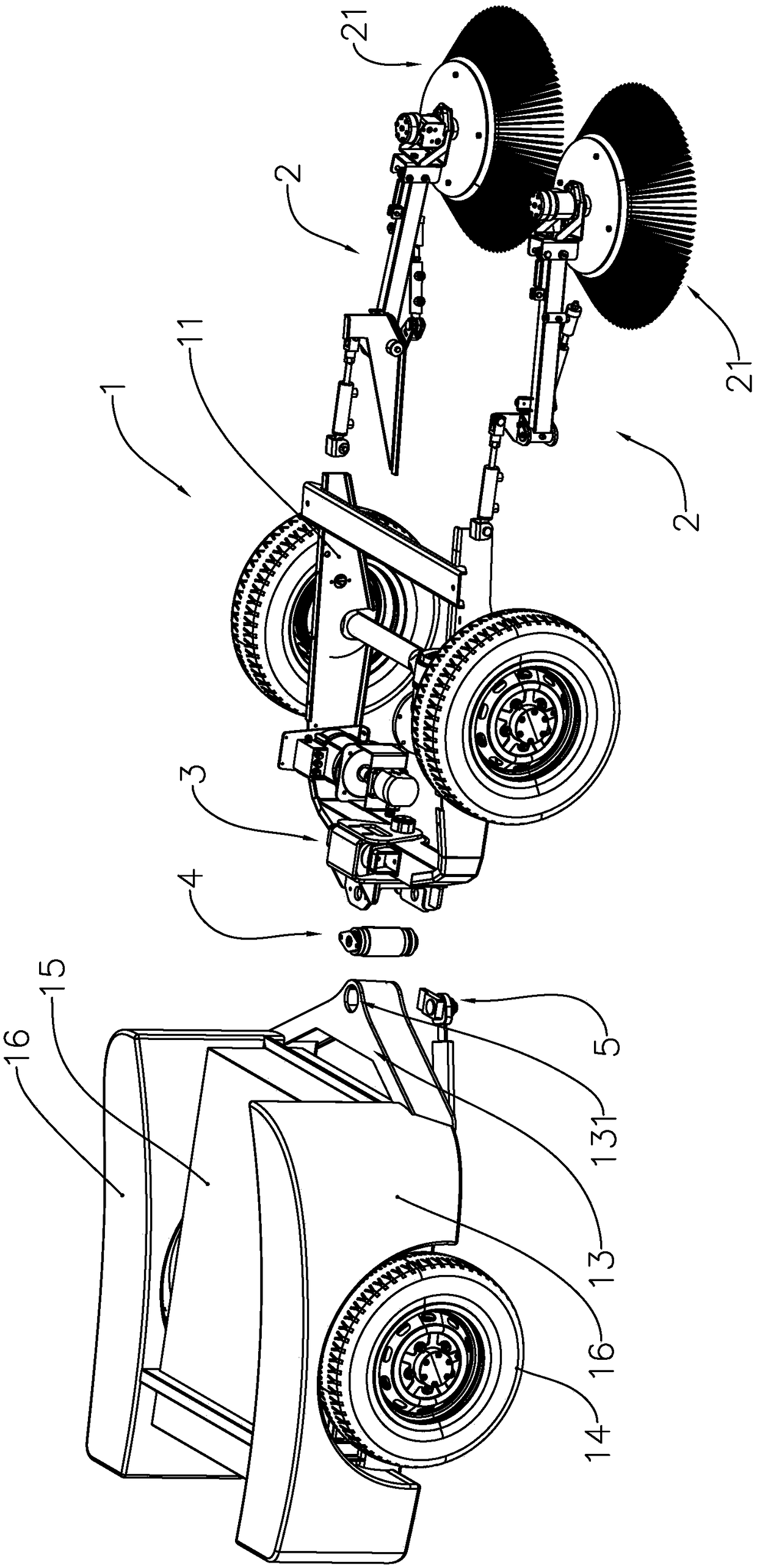

[0039] Reference Figure 1 to Figure 3 The sweeper includes a moving device and a sweeping device 2, a connecting assembly 3, an articulated bearing 4 and a single steering assembly 5. The moving device includes a front frame 11 and a rear frame 13, and the front frame 11 is provided with front wheels 12 and sweeping The brush 21, the rear wheel 14 on the rear frame 13, and the sweeping device 2 are arranged on the front frame.

[0040] Reference Figure 4 to Figure 7 , The two sweeping devices 2 are installed in front of the front frame and arranged symmetrically. The sweeping device 2 includes a sweeping brush 21, a sweeping drive unit 22, a rotating bracket 23, a vertical bracket 24, a horizontal rocker arm 26, and a retractable Place the driving unit 271, the buffer assembly 28, the second elastic member 265 and the lifting assembly. The sweeping brush 21 has a disk body and a brush located below the disk body. The sweeping brush drive unit is located above the sweeping brush ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com