Oil leaking detection and protection device for fan stationary blade adjustment hydraulic device

A technology for hydraulic devices and protection devices, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc. Splash and waste, overall compactness, oil spill reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

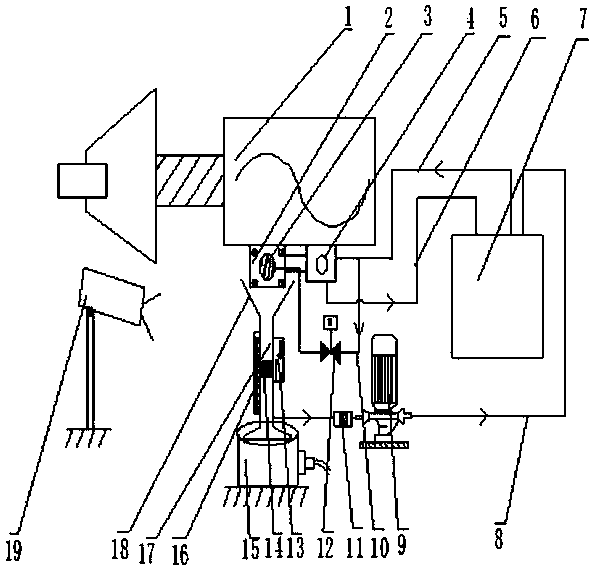

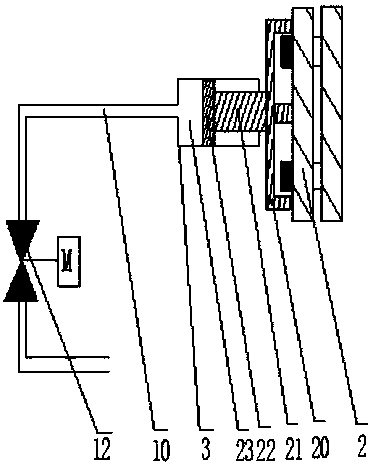

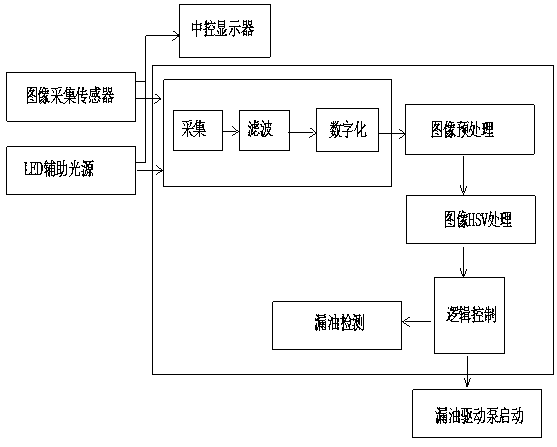

[0015] Embodiment 1: see figure 1 , figure 2 , an oil leakage detection and protection device for a fan stator blade adjustment hydraulic device, the protection device includes a steam blower unit 1, a hydraulic oil return module 2, a hydraulic locking device 3, a hydraulic drive valve 4, a drive valve oil inlet pipe 5, Drive valve oil return pipe 6, oil tank 7, oil leakage oil return pipe 8, oil leakage drive pump 9, locking device oil inlet pipe 10, filter device 11, electric control valve 12, magnetic induction switch 13, magnetic floating block 14, load cell 15 , a magnetic flap 16, an oil collection pipe 17, an oil collection tank 18 and an infrared image collector 19, a hydraulic oil return module 2 is provided below the steam-driven blower unit 1, and an oil collection tank is provided below the hydraulic oil return module 2 18. The oil collection tank 18 and the oil collection pipe 17 are extended and installed, and a load cell 15 is installed at the bottom of the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com