Special-shaped tooth dual labyrinth seal structure and special-shaped tooth impeller ring seal structure for nuclear main pump and with locating function

A technology of labyrinth seal and sealing structure, which is applied to the components, pumps, pump elements, etc. of the pumping device for elastic fluid, which can solve the problem of reduced concentricity between the mouth ring and the centrifugal pump, limited effect of preventing backflow, and medium dissipation. It can improve the efficiency of equipment, prolong its service life, and achieve the effect of non-destructive disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

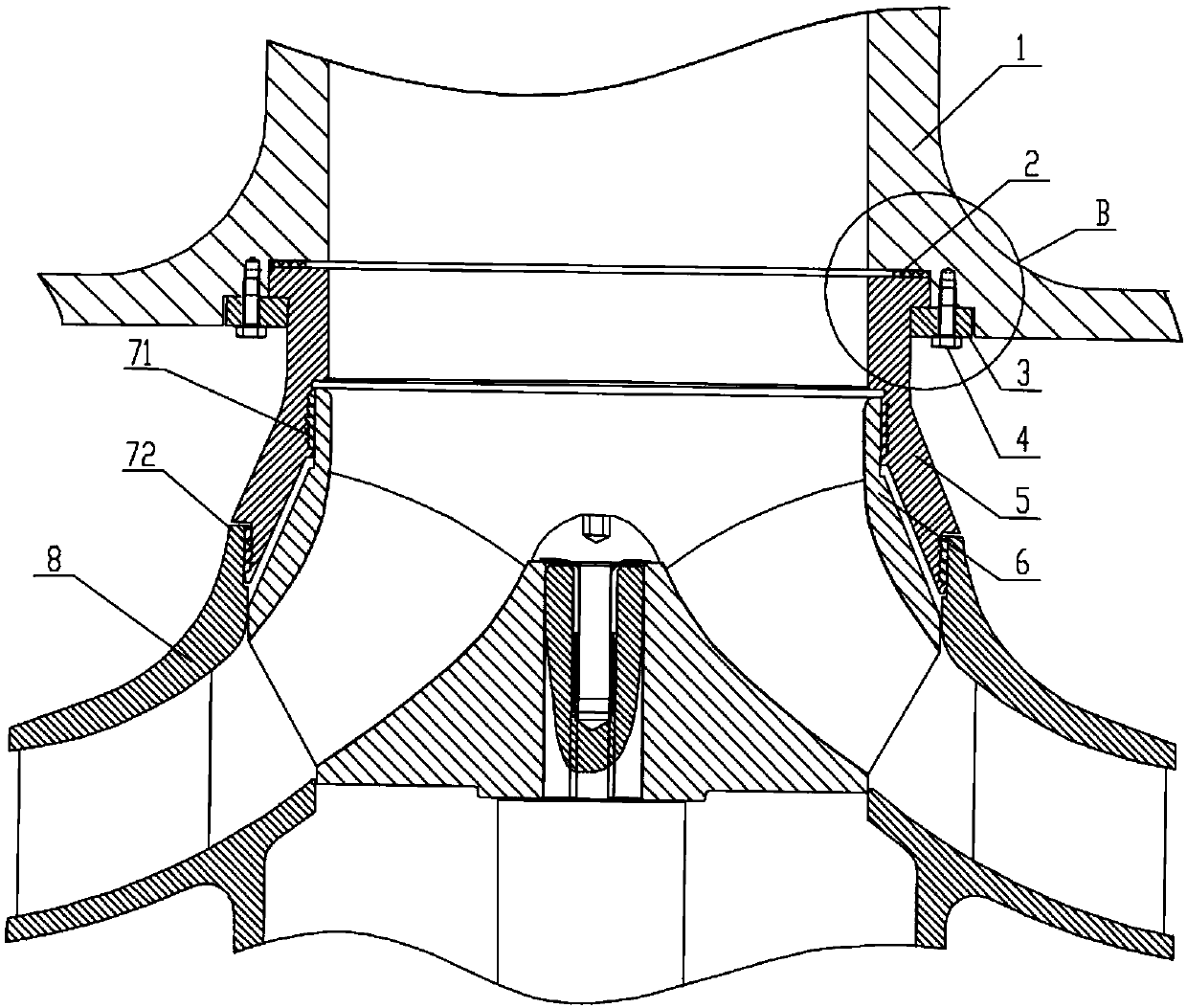

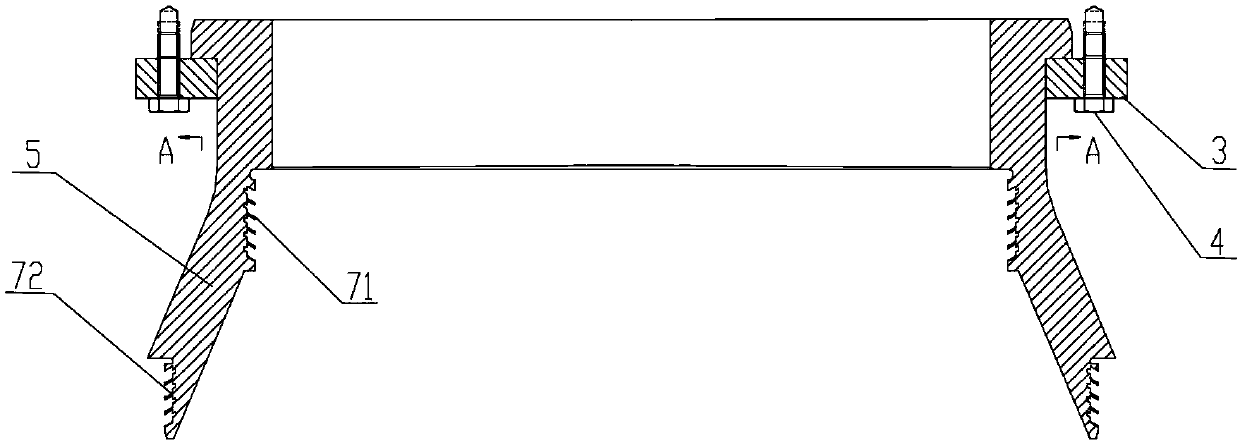

[0025] The invention provides a special-shaped tooth double labyrinth seal structure, such as Figure 5 As shown, it includes a plurality of sealing teeth, the sealing teeth are inclined to the fluid inlet side, and the leeward surface adopts a concave arc structure, and the arc angle of the arc structure is 35-60°; the formation between two adjacent sealing teeth The first sealing cavity 701; the height of the sealing teeth is the depth h of the first sealing cavity 701, and the inclination angle of the sealing teeth is the inclination of the first sealing cavity 701 The distance between two adjacent sealing teeth is the width b of the first sealing cavity 701; the upper part of the first sealing cavity 701 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com