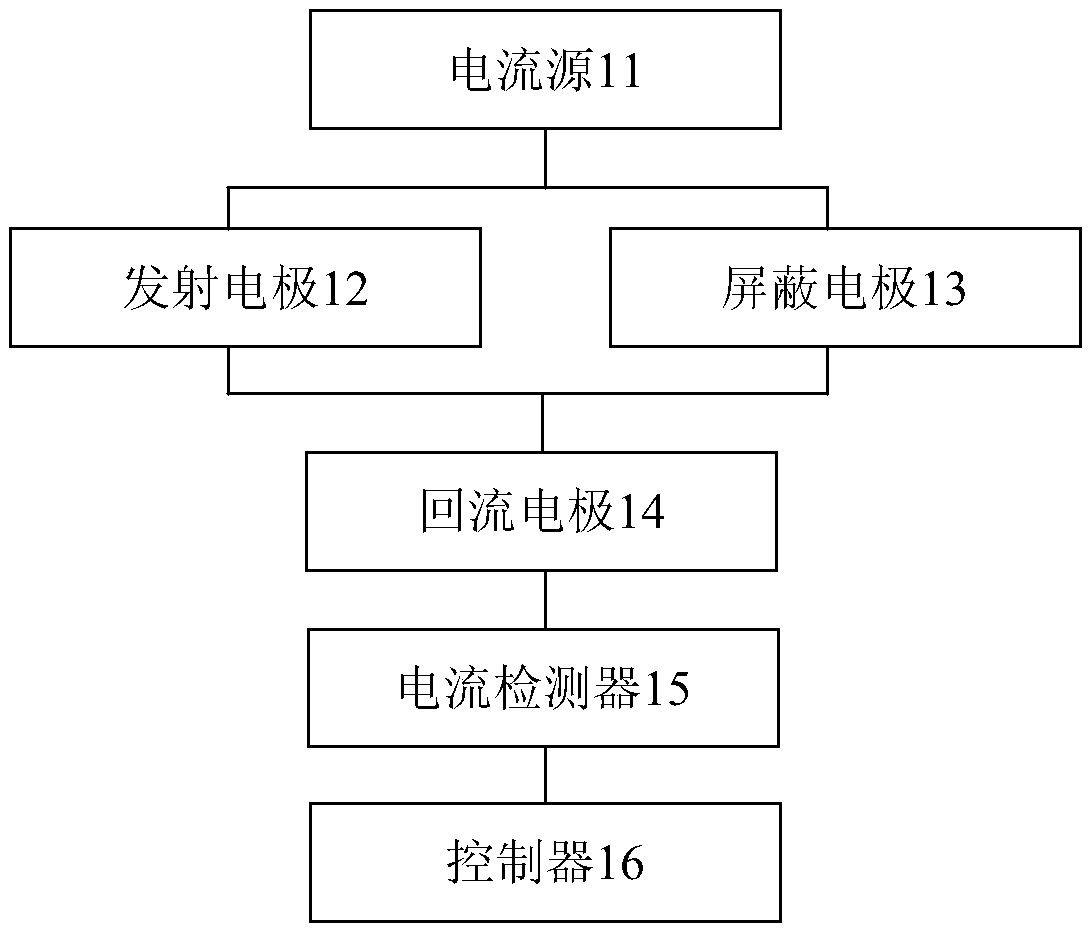

Focusing system and method of shield tunneling machine

A technology of focusing system and shield machine, applied in the field of shield, which can solve the problems of affecting the accuracy of apparent resistivity measurement, false alarms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

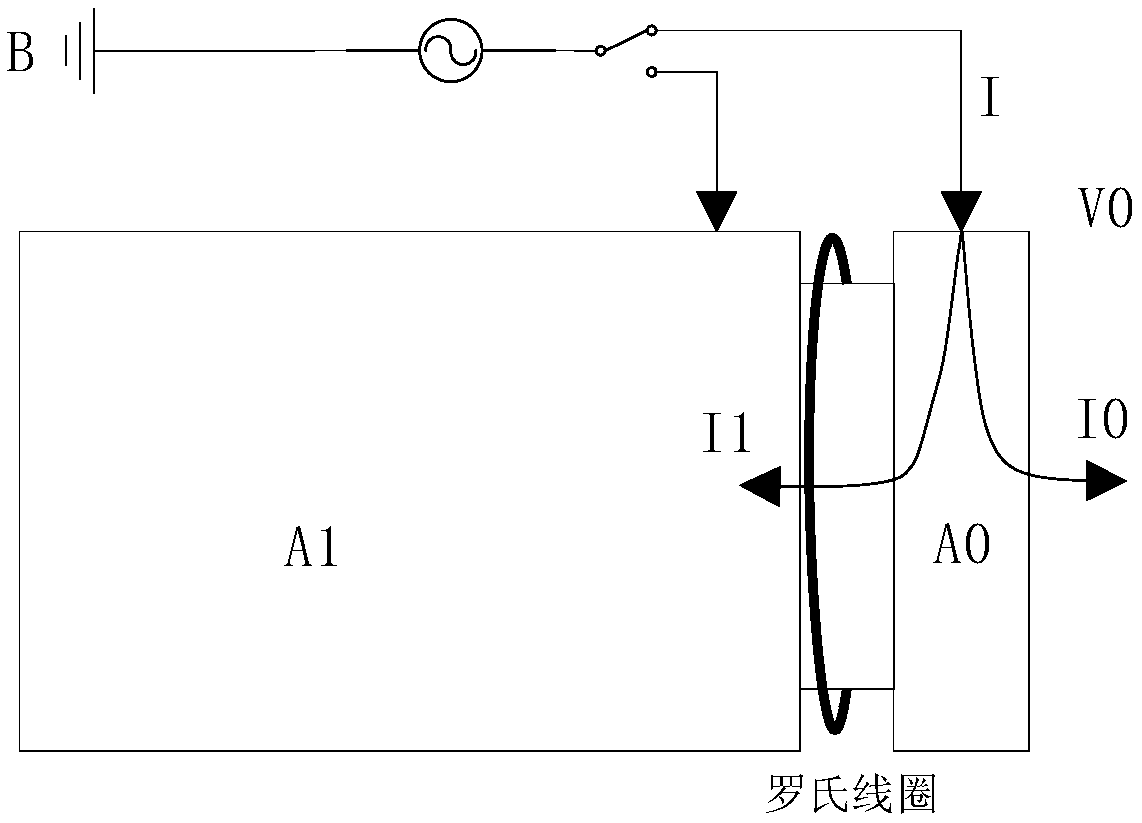

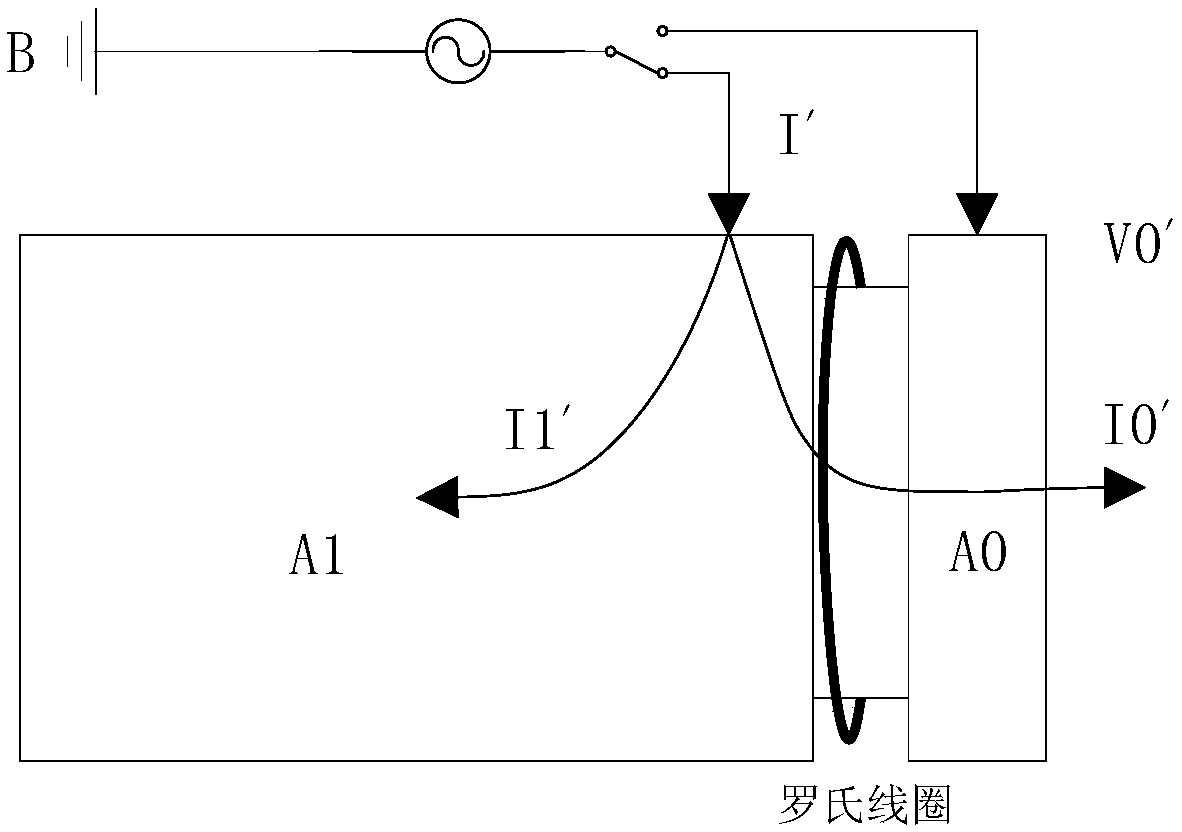

[0055]The cutter head of the shield machine (or TBM) is used as the emission electrode A0 electrode, the shield of the shield machine (or TBM) is used as the shield electrode A1 electrode, the Rogowski coil is installed between the cutter head and the shield as the current measurement coil, and the return electrode B and reference electrode N are placed on ground anchors behind (eg, 300m-500m behind) the shield machine (or TBM). The implementation of digital focus is as follows:

[0056] Mode 1: figure 2 It is a schematic structural diagram of the first mode circuit according to the preferred implementation mode of the embodiment of the present invention, such as figure 2 As shown, power is supplied to the cutter head (A0 electrode) and B electrode, the total power supply current is I, and the current flows into the cutter head and is divided into two parts, one part of the current (I0) directly flows into the formation and returns to the B electrode, and the other part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com