Pretreatment method for ore rock

A technology for pretreatment and ore rock, which is used in surface mining, earthwork drilling, underground mining, etc., can solve the problems of hydraulic fracturing ore rock pretreatment method to be improved, and achieve good improvement effect and reduce caving ore rock blocks. degree, the effect of increasing the degree of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

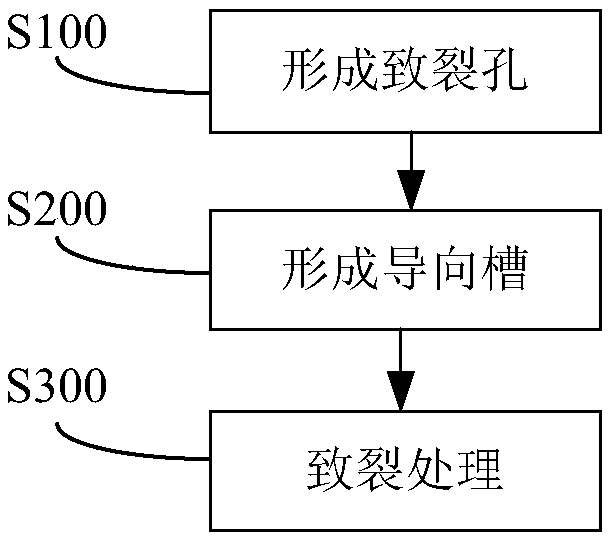

Method used

Image

Examples

Embodiment 1

[0056] Utilize the method for the embodiment of the present invention to carry out the method for pretreatment of stope ore as follows:

[0057] 1. According to the design plan of the natural caving mining method, the corresponding stope project is formed. The structure of the stope is as follows figure 2 As shown, it mainly includes the bottom-drawing level (composed of bottom-drawing tunnels), the bottom ore outlet structure (composed of ore-collecting system and ore-out approach, generally in the form of a funnel or ore-accumulating trough, and the ore-out approach is generally Arranged in a herringbone style) and along the main transport alley. There are vein-piercing roadways and vein-along roadways arranged horizontally on the upper part of the ore blocks in the stope. The height of the ore blocks varies, up to hundreds of meters or even hundreds of meters; the vein-piercing roadways are arranged along the direction of the ore body, with an interval of about 50 meters. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com