Slope support structure and support method

A technology for supporting structures and slopes, applied in infrastructure engineering, excavation, construction, etc., can solve problems such as collapse, insufficient support force, poor stability, etc., to achieve large-scale implementation, simple and effective methods, and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

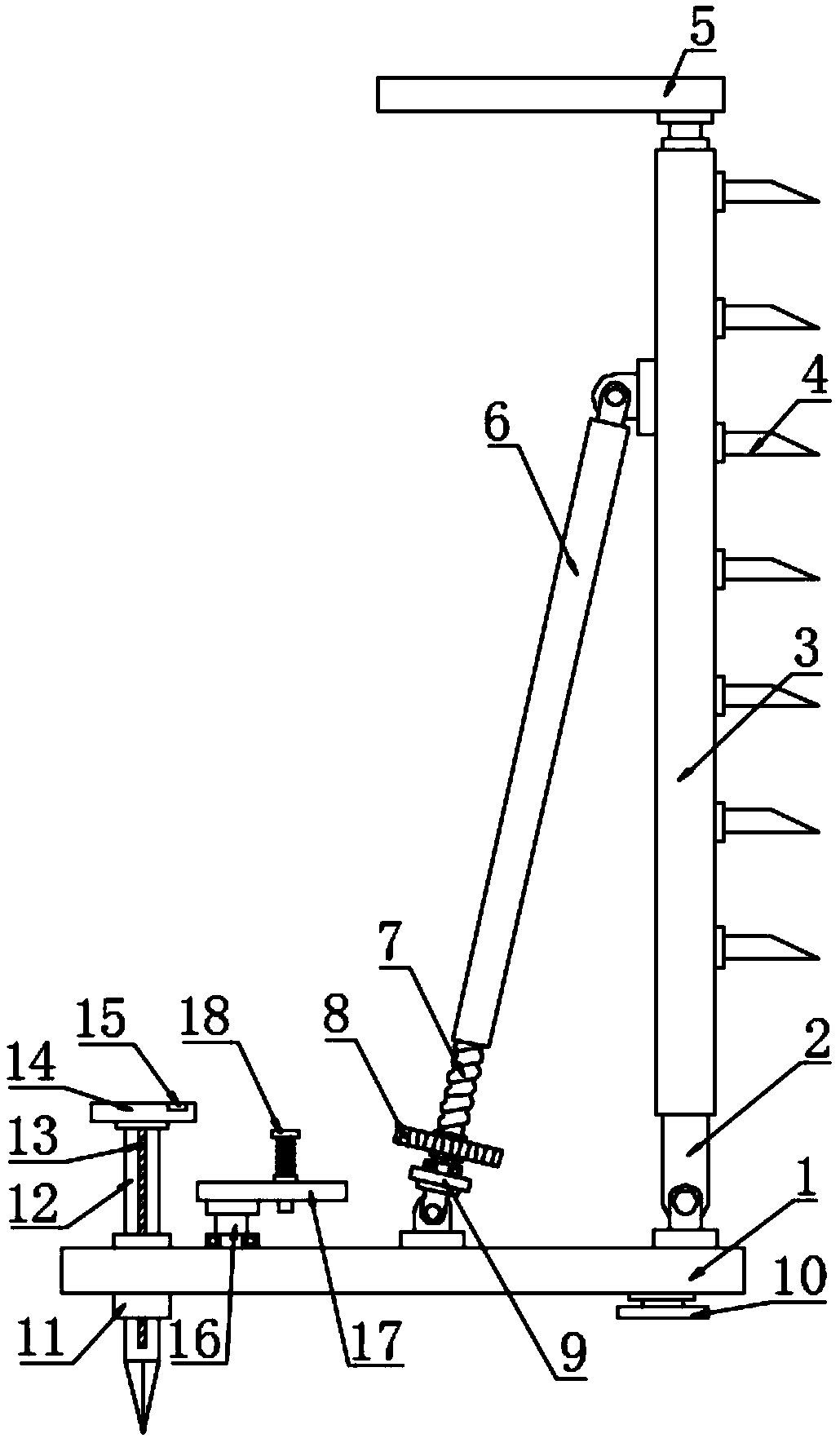

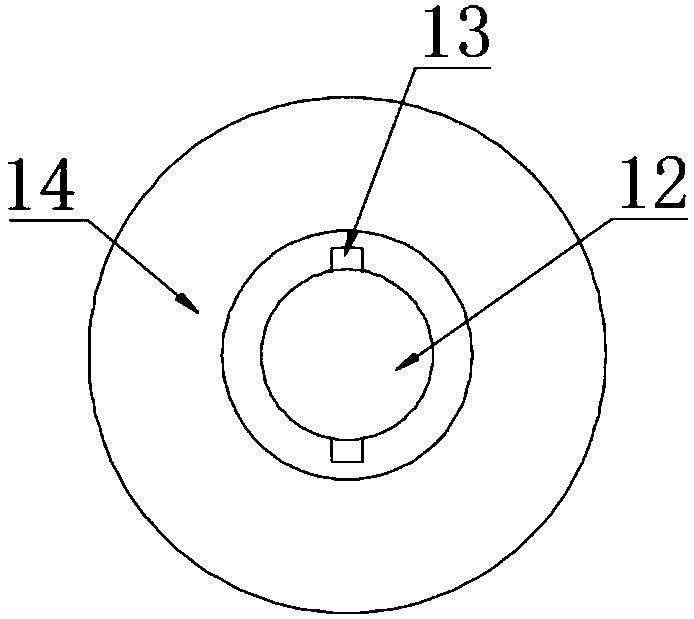

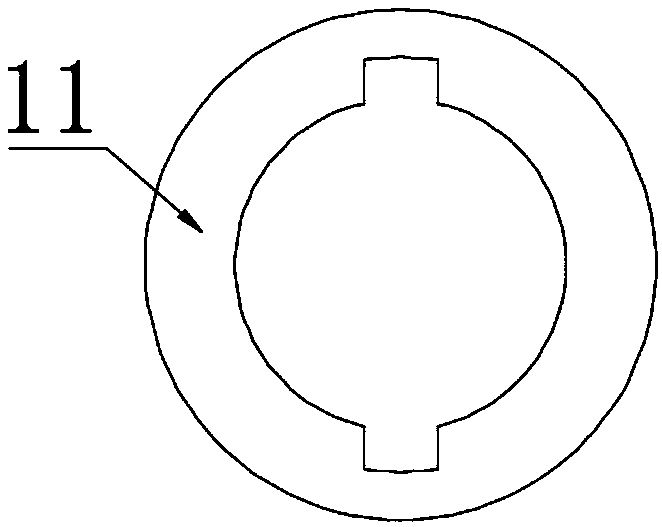

[0028] In the embodiment of the present invention, a slope support structure includes a base plate 1, a telescopic plate 3, a threaded cylinder 6, a screw rod 7, a drill rod 12 and a pressure plate 17; the right end of the base plate 1 is hinged with a fixed plate 2, and the fixed plate 2. The upper part is covered with a telescopic plate 3, the left surface of the upper part of the telescopic plate 3 is rotated and connected to the upper end of the threaded cylinder 6, the lower part of the threaded cylinder 6 is threaded to connect with the screw rod 7, and the bearing at the lower end of the screw rod 7 is connected to the movable base 9 by rotation, and the movable base 9 is connected to the bottom plate 1 Rotational connection, the lower part of the screw rod 7 is fixedly connected with the adjustment wheel 8, wherein a triangle is formed by the bottom plate 1, the connecting body of the fixed plate 2 and the telescopic plate 3, the connecting body of the threaded cylinder ...

Embodiment 2

[0032] In the embodiment of the present invention, a slope support structure includes a base plate 1, a telescopic plate 3, a threaded cylinder 6, a screw rod 7, a drill rod 12 and a pressure plate 17; the right end of the base plate 1 is hinged with a fixed plate 2, and the fixed plate 2. The upper part is covered with a telescopic plate 3, the left surface of the upper part of the telescopic plate 3 is rotated and connected to the upper end of the threaded cylinder 6, the lower part of the threaded cylinder 6 is threaded to connect with the screw rod 7, and the bearing at the lower end of the screw rod 7 is connected to the movable base 9 by rotation, and the movable base 9 is connected to the bottom plate 1 Rotational connection, the lower part of the screw rod 7 is fixedly connected with the adjustment wheel 8, wherein a triangle is formed by the bottom plate 1, the connecting body of the fixed plate 2 and the telescopic plate 3, the connecting body of the threaded cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com