Thermal treatment process capable of improving amplitude of cutter bar of ultrasonic cutter

An ultrasonic knife and knife shank technology is applied in the field of heat treatment technology to achieve the effects of improving alloy strength, reducing two-way tensile stress and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

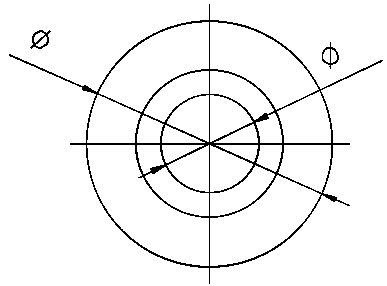

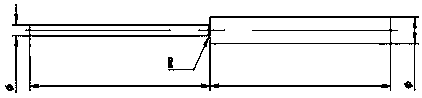

[0044] Such as figure 1 and figure 2 As shown, the tool bar is made of Ti-6Al-4V alloy material, and the shape of the tool bar is a stepped horn. The center of the tool bar in the length direction is the luffing node. Diameter shank, the diameter ratio of the small diameter shank to the large diameter shank is 5:2, and the node is designed with R=0.5.

[0045] Its heat treatment methods include:

[0046] (1) Raw material preparation: Ti-6Al-4V hot-rolled annealed bar with a diameter of 8.05mm and a length of 100mm, in which the contents of Ti, Al, and V elements are 89.62%, 6.05%, and 4.13%, respectively, and the impurity content is 0.4 wt.%; the tensile strength is 1005 (Mpa), the elongation is 14.5%, and the reduction of area is 34%;

[0047] (2) Solution treatment: heat the sample to 930°C at a heating rate of 95°C / min, keep it warm for 60s, and then place the sample in air to cool rapidly to room temperature;

[0048] (3) Aging treatment: Heat the above-mentioned soli...

Embodiment 2

[0052] Such as figure 1 and figure 2 As shown, the tool bar is made of Ti-6Al-4V alloy material, and the shape of the tool bar is a stepped horn. The center of the tool bar in the length direction is the luffing node. Diameter shank, the diameter ratio of the small diameter shank to the large diameter shank is 5:2, and the node is designed with R=0.5.

[0053] Its heat treatment methods include:

[0054] (1) Raw material preparation: Ti-6Al-4V hot-rolled annealed bar, with a diameter of 8.05mm and a length of 100mm, in which the contents of Ti, Al, and V elements are 89.62%, 6.05%, and 4.13%, respectively, and the impurity content is 0.4wt.%; the tensile strength is 1005 (Mpa), the elongation is 14.5%, and the reduction of area is 34%;

[0055] (2) Solution treatment: heat the sample to 940°C at a heating rate of 105°C / min, keep it warm for 60s, and then place the sample in air and cool it rapidly to room temperature;

[0056] (3) Aging treatment: Heat the above-mentioned...

Embodiment 3

[0060] Such as figure 1 and figure 2 As shown, the tool bar is made of Ti-6Al-4V alloy material, and the shape of the tool bar is a stepped horn. The center of the tool bar in the length direction is the luffing node. Diameter shank, the diameter ratio of the small diameter shank to the large diameter shank is 5:2, and the node is designed with R=0.5.

[0061] Its heat treatment methods include:

[0062] (1) Raw material preparation: Ti-6Al-4V hot-rolled annealed bar, with a diameter of 8.05mm and a length of 100mm, in which the contents of Ti, Al, and V elements are 89.62%, 6.05%, and 4.13%, respectively, and the impurity content is 0.4wt.%; the tensile strength is 1005 (Mpa), the elongation is 14.5%, and the reduction of area is 34%;

[0063] (2) Solution treatment: heat the sample to 950°C at a heating rate of 112°C / min, keep it warm for 60s, and then place the sample in air and cool it rapidly to room temperature;

[0064] (3) Aging treatment: Heat the solid-solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com