Stirring device modified structure

A stirring device and stirring rod technology, applied in biochemical cleaning devices, enzymology/microbiology devices, biochemical instruments, etc., can solve problems such as uneven mixing of materials, and achieve the effect of improving uniformity and amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

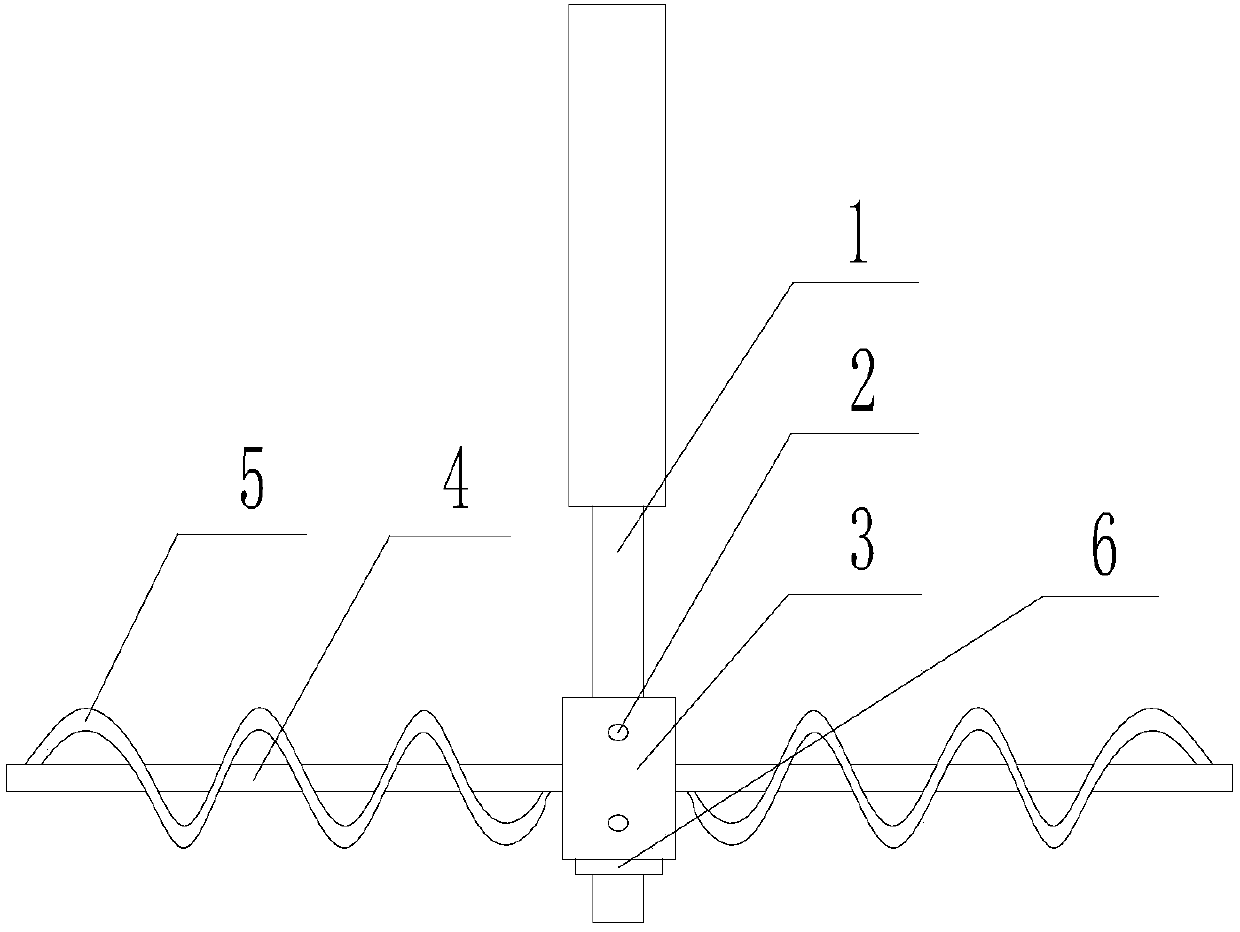

[0026] Such as figure 1 As shown, an improved structure of a stirring device includes a rotating shaft 1, a sleeve 3 is detachably sleeved on the rotating shaft 1, and the sleeve 3 is detachably connected to the rotating shaft 1 through a bolt 2. The sleeve Two stirring rods 4 are arranged on the cylinder 3, the stirring rods 4 are arranged vertically to the axial direction of the sleeve 3, and the wave-shaped stirring blades 5 are arranged on the said stirring rods 4, and the peak distribution of the wave-shaped stirring blades 5 On both sides of the rotating shaft 1; the width of the wave-shaped stirring blade 5 is 2 / 3 of the diameter of the stirring rod 4; the distance between the top of the crest and the outer wall of the stirring rod 4 is 2-3 times of the diameter of the stirring rod 4 .

Embodiment 2

[0028] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and a limiting plate 6 is provided on the rotating shaft 1 below the sleeve 3; the rotating shaft 1 is a telescopic rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com