Material conveying system

A conveying system and material technology, applied in the direction of conveyors, transportation and packaging, loading/unloading, etc., can solve problems affecting production quality control, raw material quality changes, etc., to achieve the effect of reducing impact and uniform raw material quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

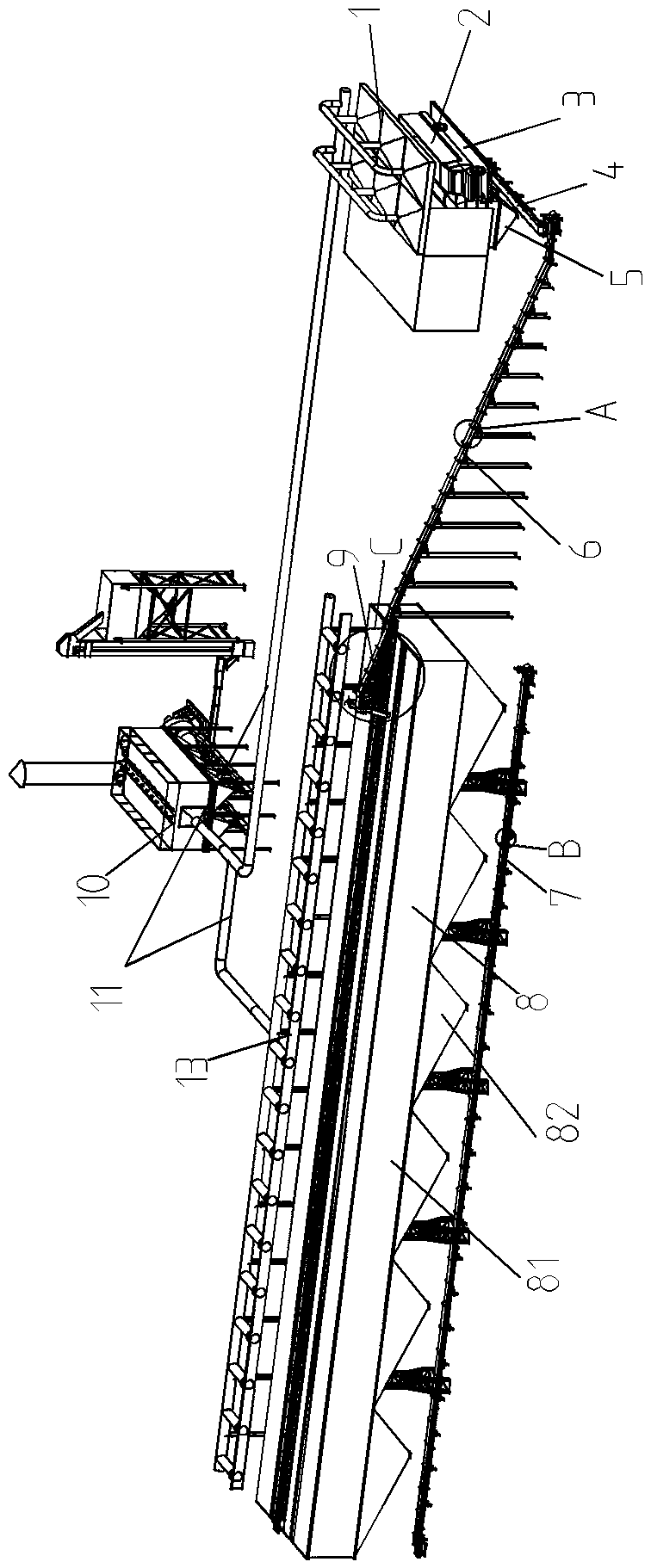

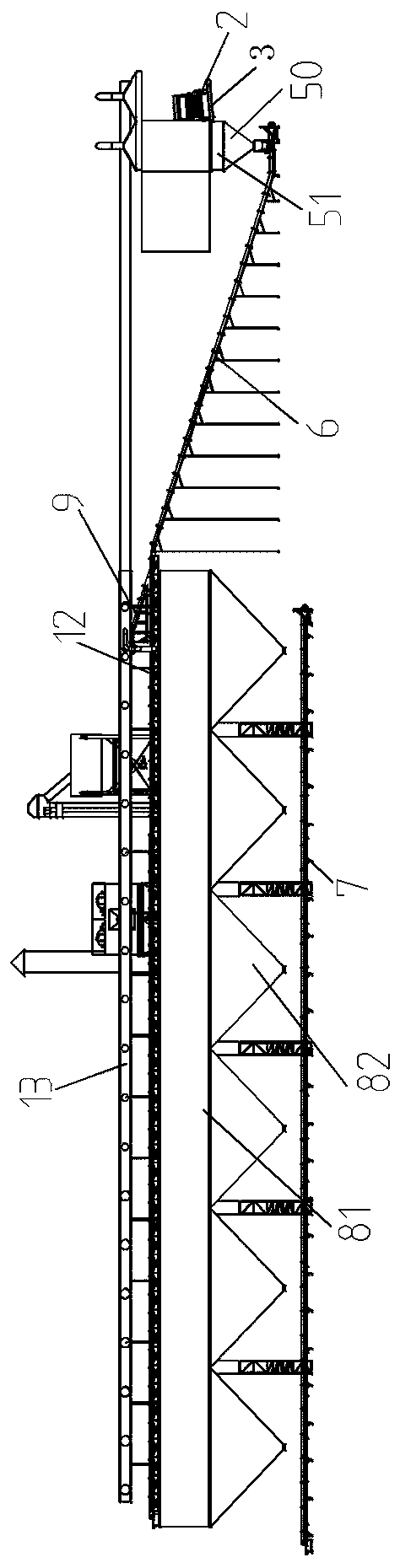

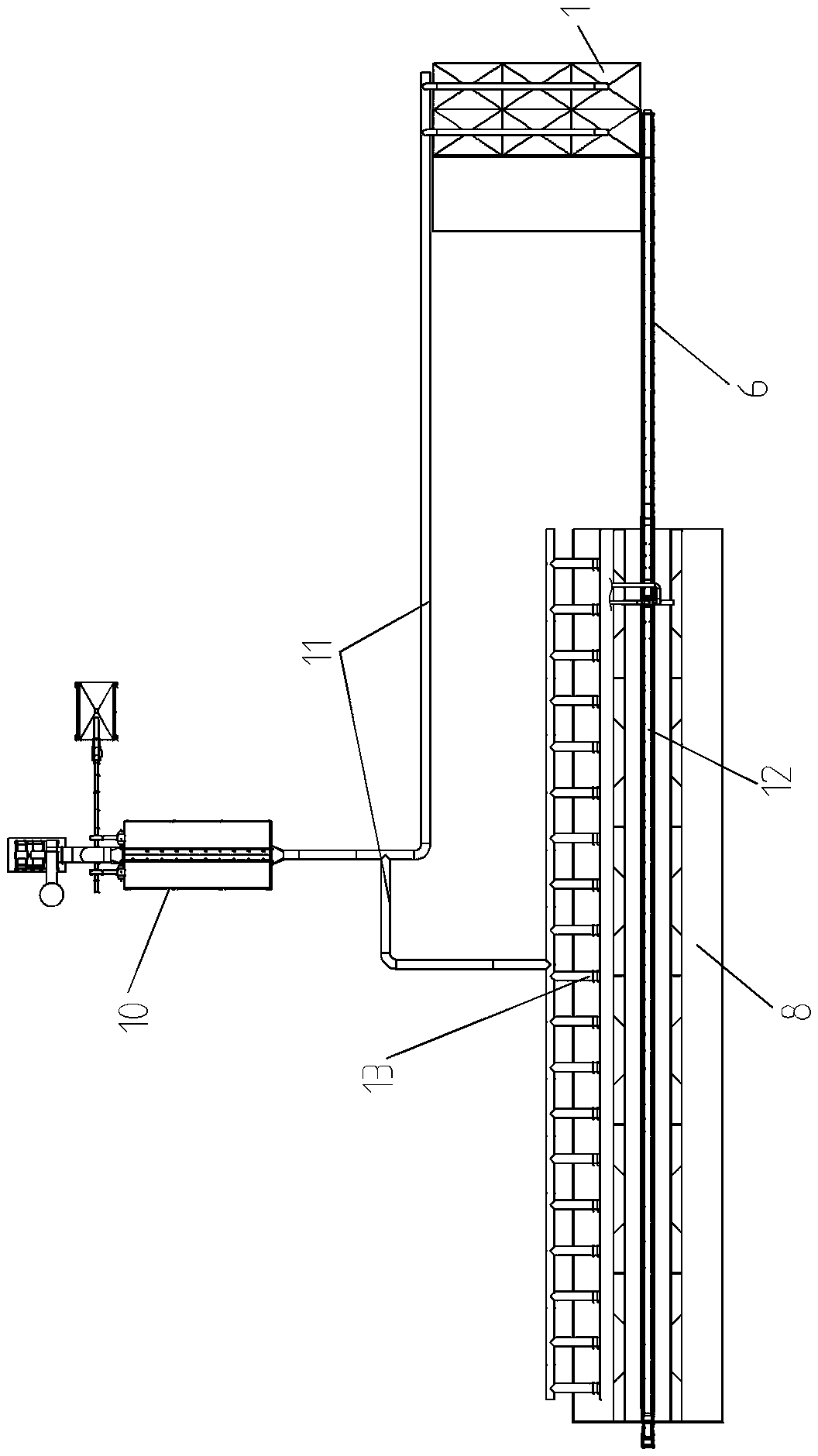

[0023] The specific embodiment of the material conveying system provided by the present invention, such as Figure 1 to Figure 7 As shown, the material conveying system in this embodiment specifically includes a hydraulic flap device 3 , a receiving bin 5 , a conveyor belt transfer device 100 , a storage bin 8 and a conveyor belt retrieving device 7 arranged in sequence.

[0024] Among them, the material receiving bin 5 is used to accept materials, and the material is generally dumped into the receiving bin 5 by the transport vehicle 2, and then the conveyer belt transfer device 100 receives the materials falling from the receiving bin 5 and transfers them to the storage material. In the bin 8, since the storage bin 8 has a plurality of mutually independent storage chambers, the material is discharged to the conveyor belt reclaimer 7 through different st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com