An asymmetric stern structure of a ship

An asymmetric and stern technology, applied in the direction of hull parts, hull, ship construction, etc., can solve the problems of high resistance and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

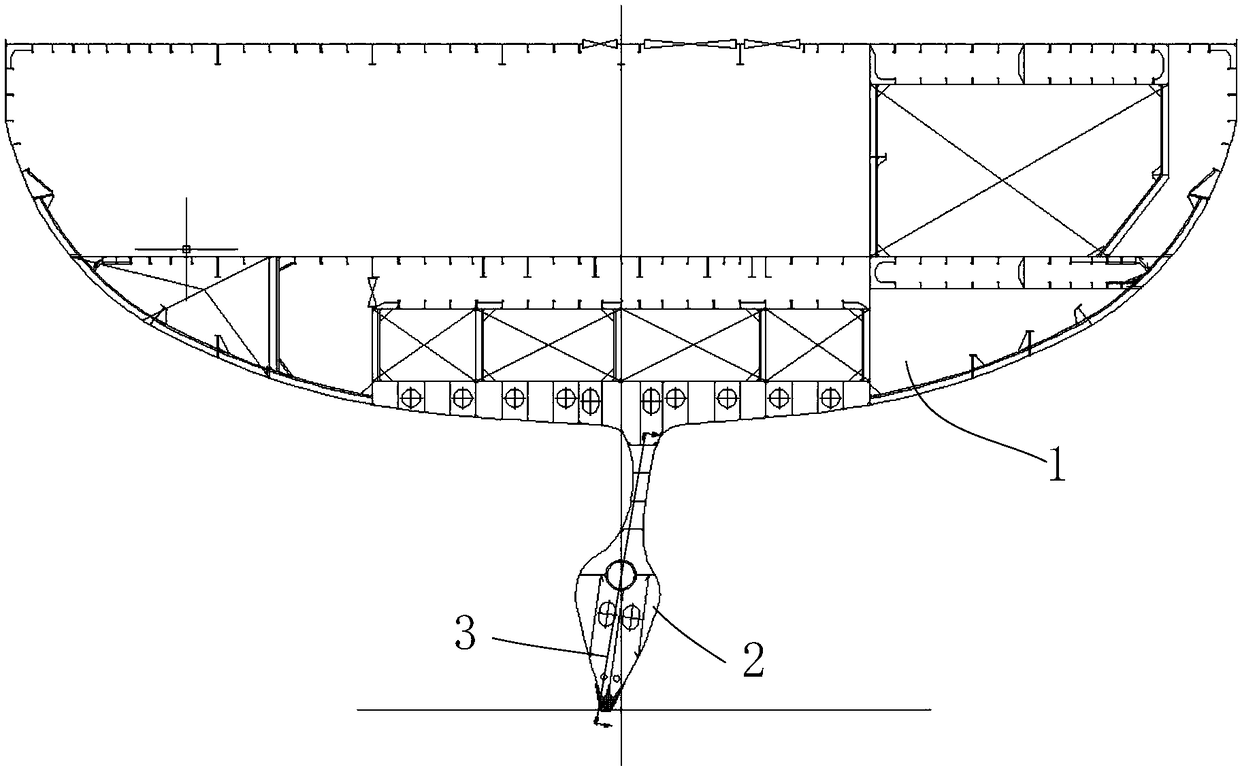

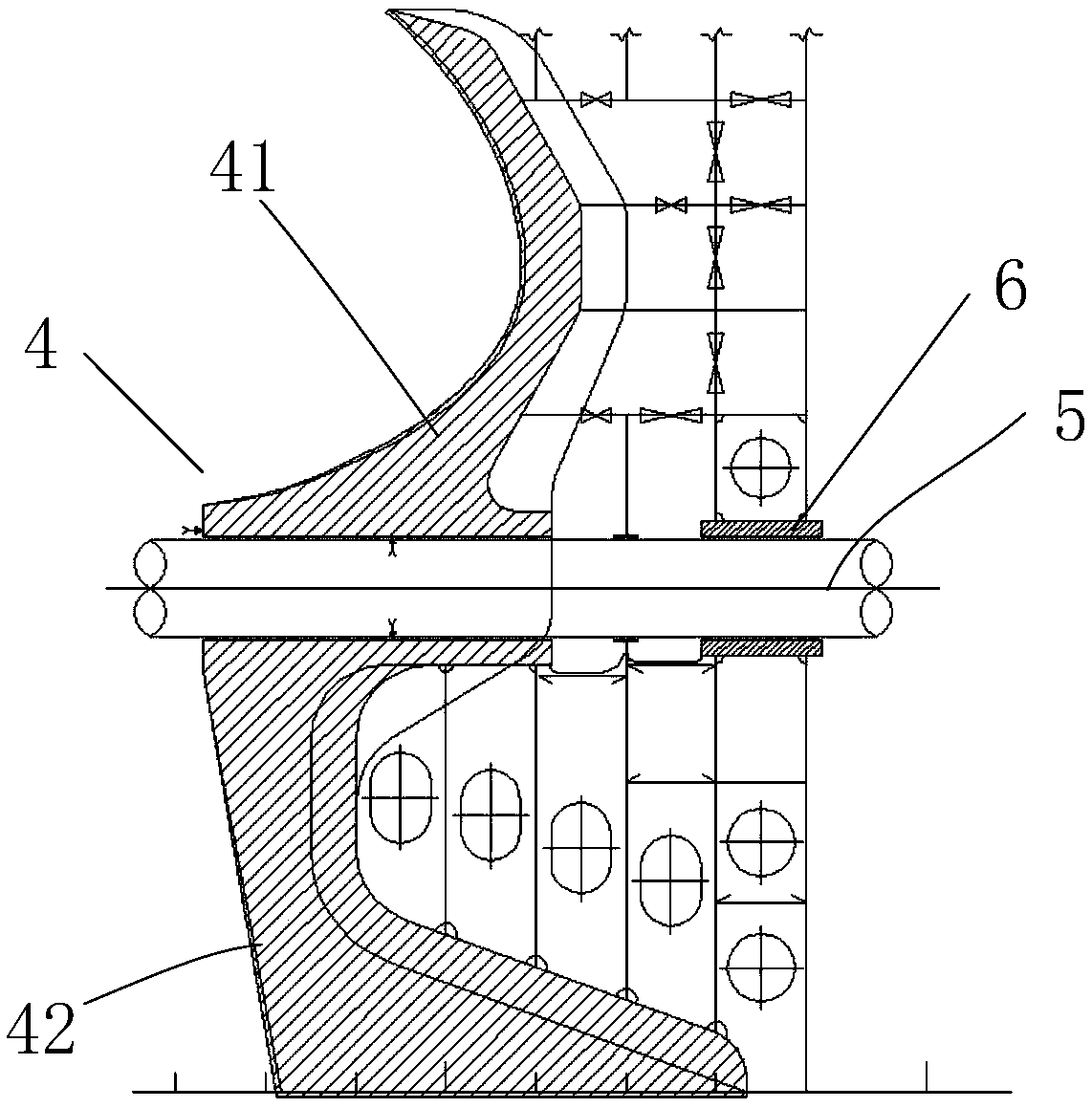

[0017] Such as Figure 1-2 As shown, an asymmetric stern structure of a ship includes a hull 1, a stern 2 is provided at the bottom of the hull 1, the longitudinal section of the stern 2 is dagger-shaped, and the longitudinal centerline 3 of the stern 2 faces the side of the hull 1 Offset, the stern 2 includes a hub steel casting 4, and the hub casting 4 includes an integrally formed first part 41 and a second part 42, the first part 41 and the second part 42 are U-shaped in cross section and opposite in direction , the longitudinal section of the first part 41 is rectangular and radial at both ends, the width of the longitudinal section of the second part 42 first increases and then decreases along the direction of the longitudinal centerline 3, the middle part of the hub casting 4 is provided with a propeller stern shaft 5, and the propeller stern shaft 5 Located on the longitudinal centerline of the hull 1, the front end of the propeller stern shaft 5 is provided with a ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com