Fiber cutting device for continuous fiber reinforced composite material 3D printer

A technology for enhancing composite materials and 3D printers, which can be used in additive processing, manufacturing auxiliary devices, processing material handling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

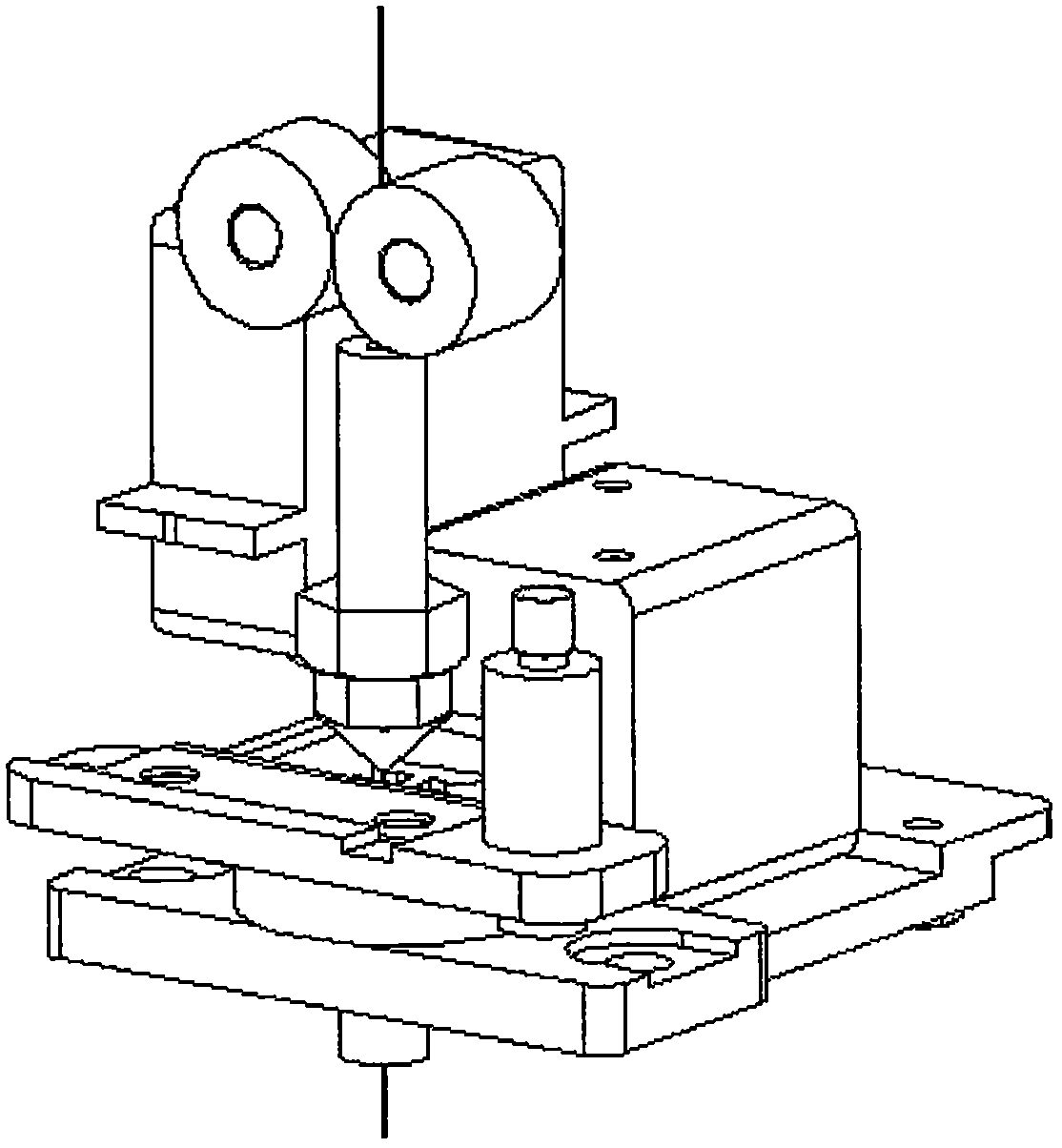

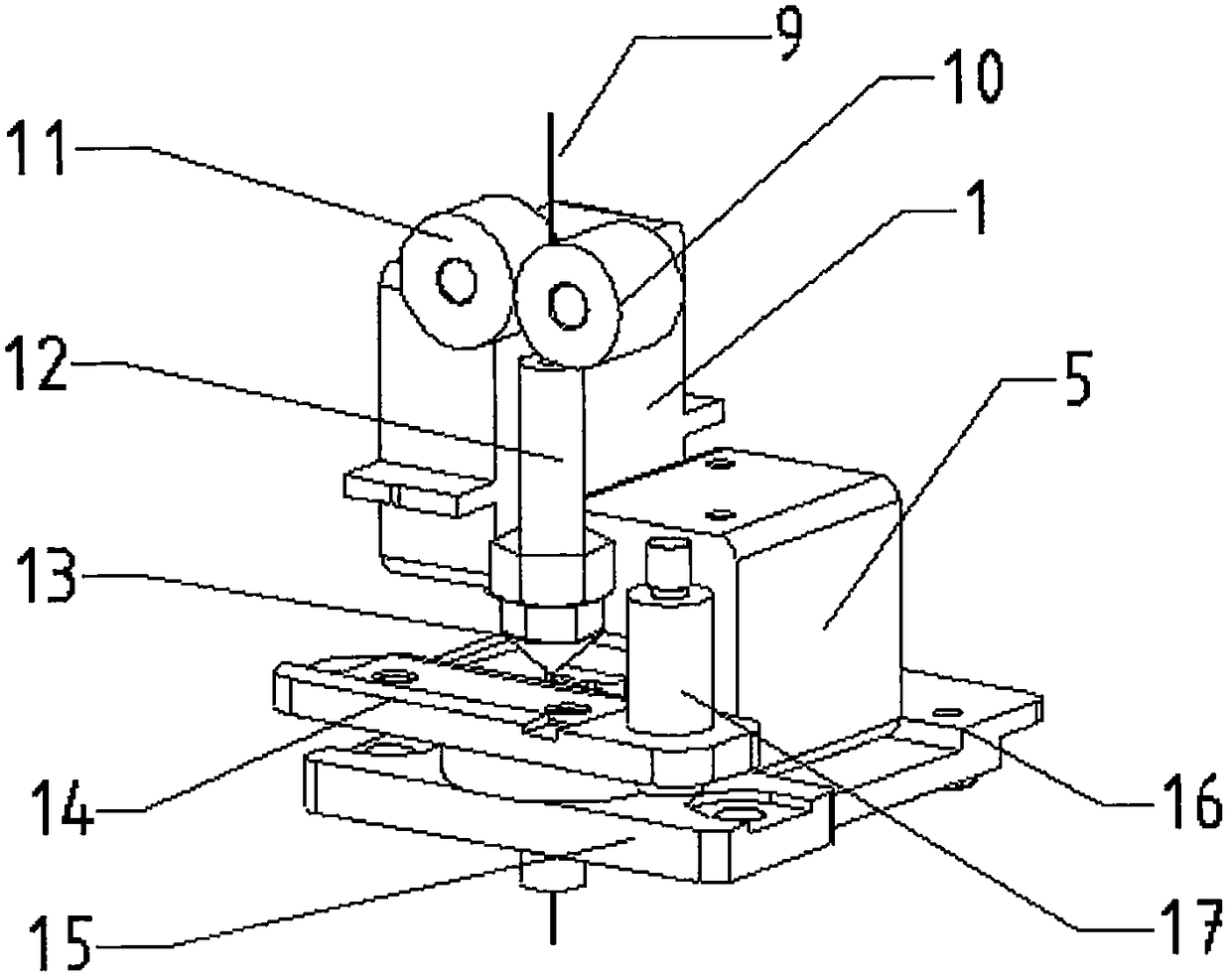

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] The invention belongs to a fiber filament cutting device of a continuous fiber reinforced composite material 3D printer, and the device mainly includes a cutting mechanism and a clamping mechanism.

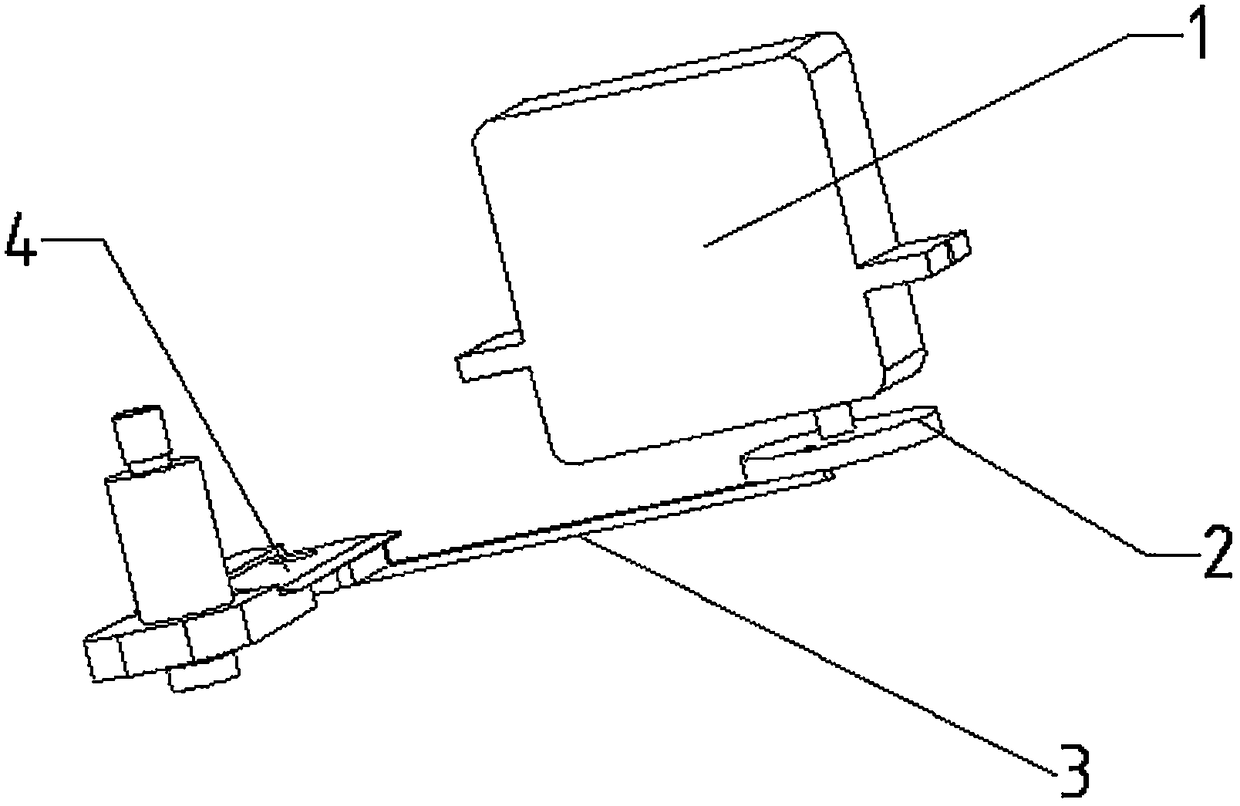

[0013] The realization of the cutting function is based on the principle of the connecting rod structure, and the power is provided by the servo module 1. A disc 2 with a hole is connected to the output shaft of the servo module 1. The servo module 1 connects the tool with the connecting rod 3 connected to the disc 2. One end of the fixing part 14 is connected, and the other end of the tool fixing part 14 is fixed by a positioning shaft 17, and one end of the positioning shaft 17 is a threaded structure, which is fixed on the printer nozzle integration device, and the other end passes through the tool fixing part 14 and is positioned by a jump ring. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com