A sheet metal processing system

A sheet metal processing, sheet metal technology, applied in metal processing, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of low processing efficiency, many transfer links, damage, etc., to improve processing efficiency, save transfer links, save money The effect of human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

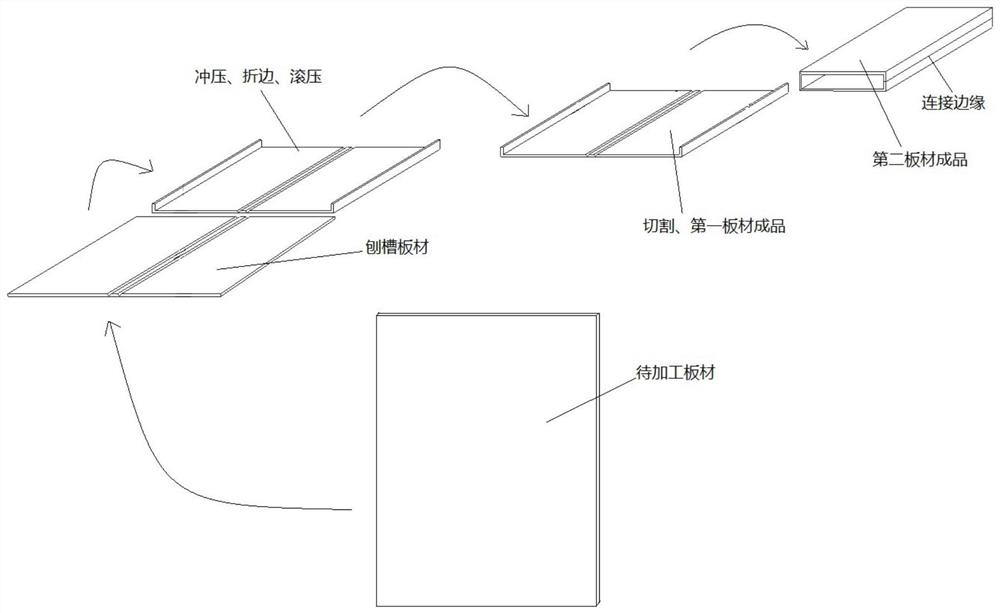

[0032] The embodiment of the present application discloses a board processing system, which is used to solve the problem that there are many transfer links in the existing board processing, the processing time is long, waste of manpower, and it is easy to cause mechanical collision or artificial damage to the transfer board, which will cause the board to be scratched technical problems or risk of deformation.

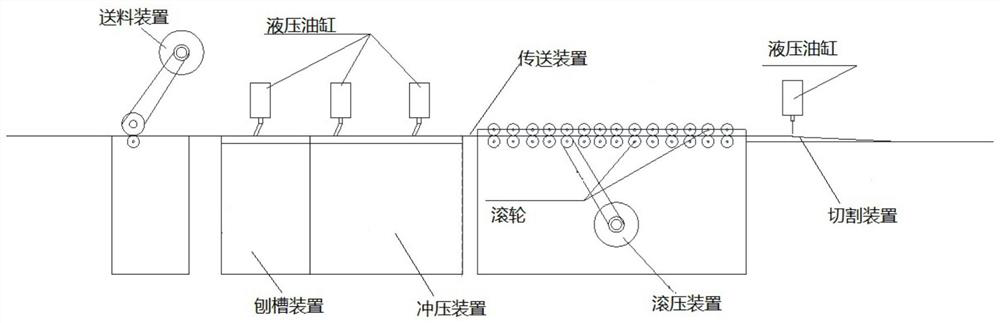

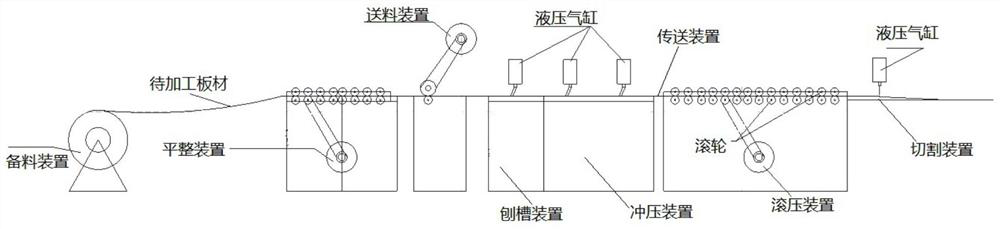

[0033] see figure 1 and image 3 , an embodiment of a plate processing system provided by the present application, including: a feeding device, a grooving device, a punching device, a rolling device, a cutting device and a conveying device;

[0034] The feeding device is used to send the plate to be processed into the grooving device;

[0035] The grooving device is used to perform grooving treatment at the first preset position on the plate to be processed to obtain a grooved plate with a notch, and send the grooved plate to the conveying device, so that the conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com