CNC machining all-in-one machine for high precision slotted nuts

A slotted nut, high-precision technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of low degree of automation, rough processing, low processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

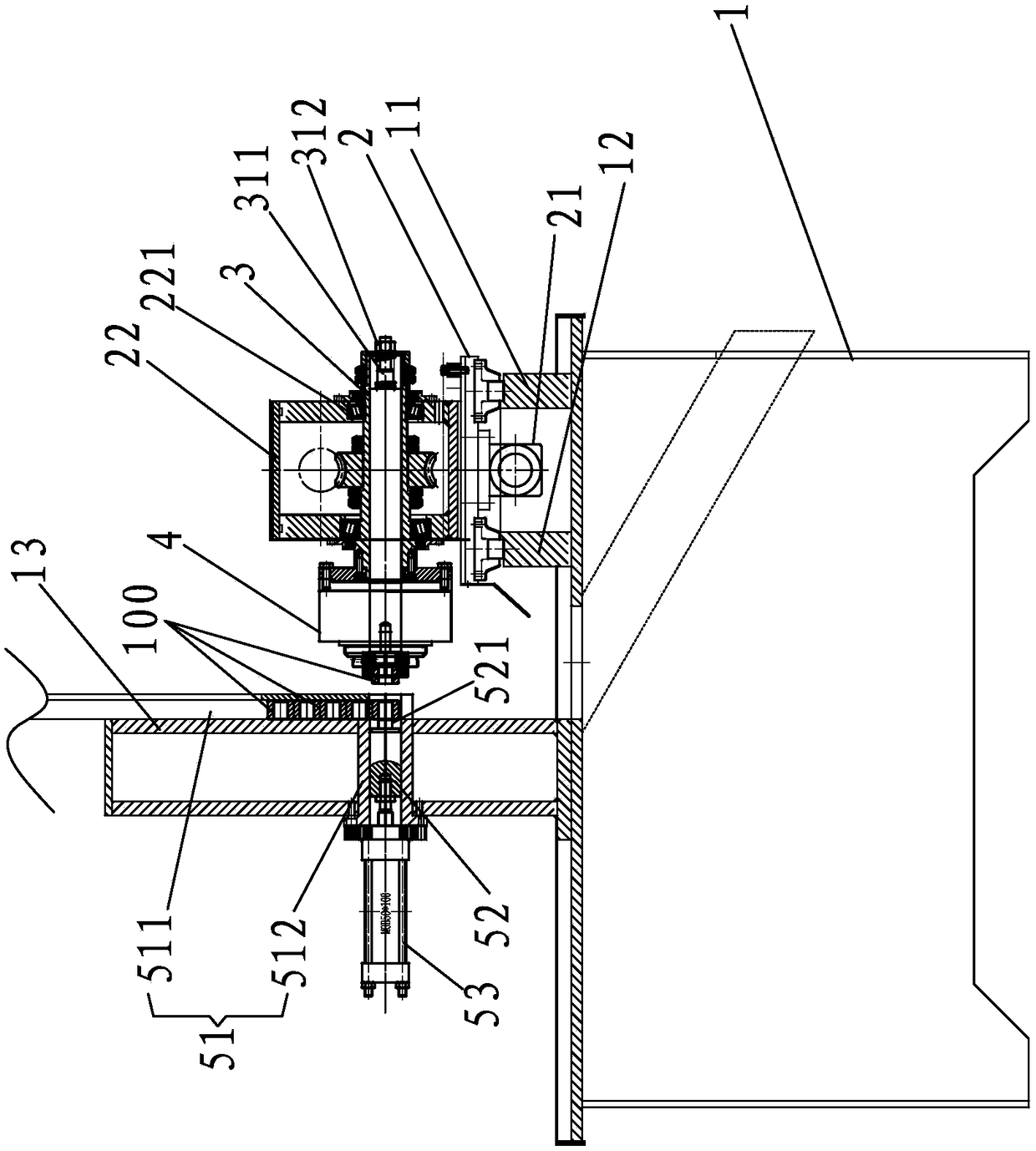

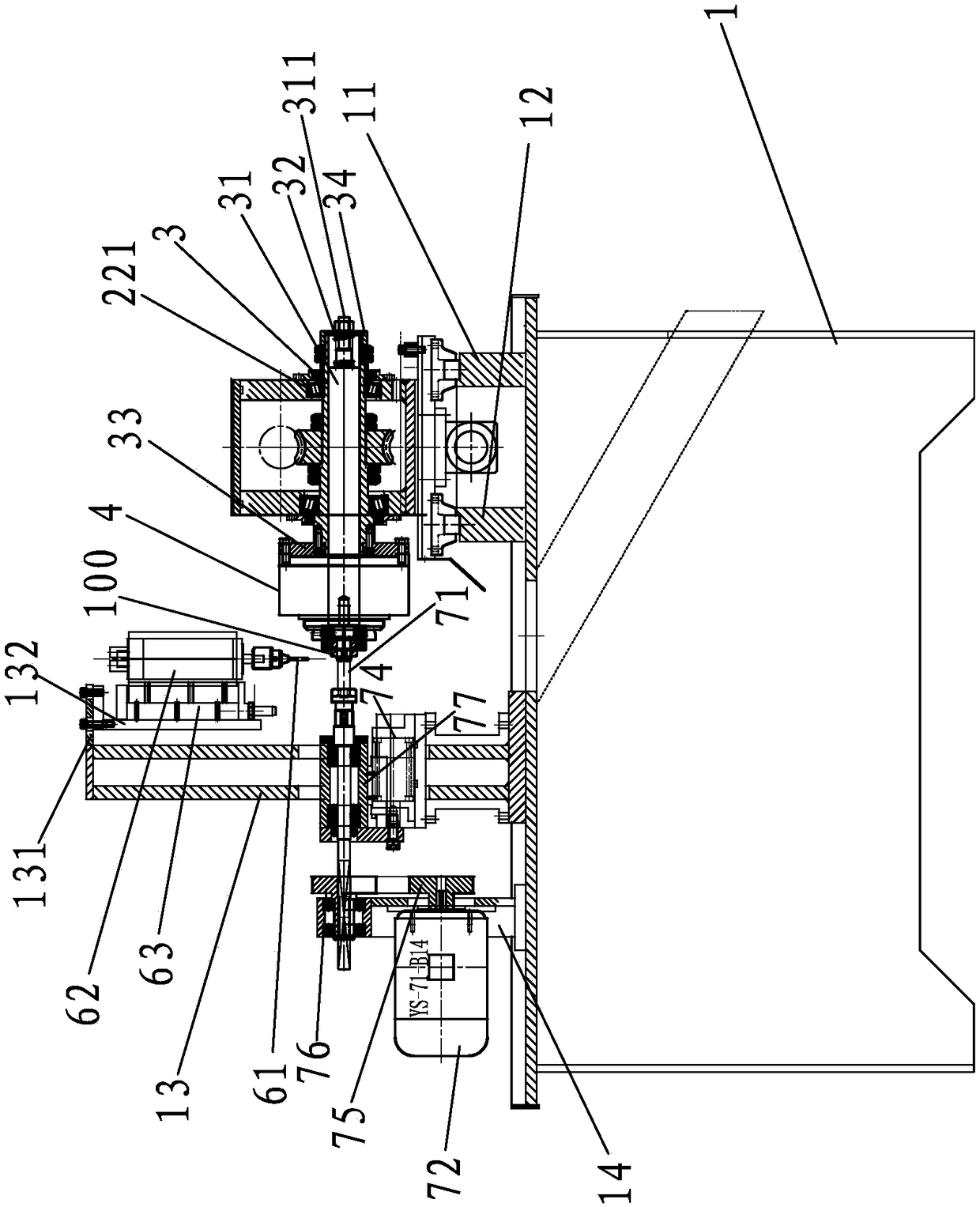

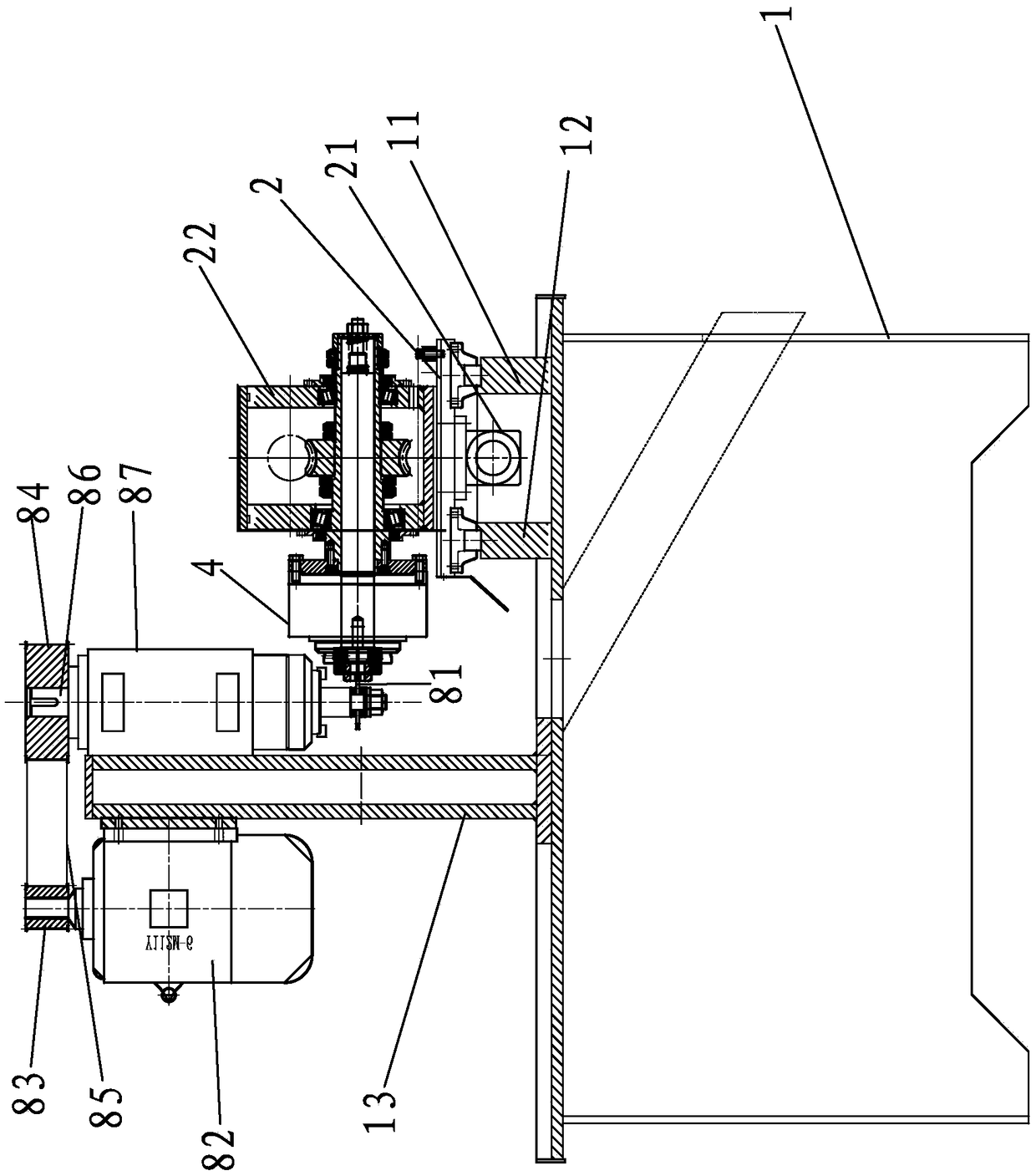

[0022] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

[0023] The CNC machining all-in-one machine of the high-precision slotted nut of the present invention, such as Figure 1-4 As shown, the machine base 1 is included, the machine base 1 is a square hollow seat body, the top front of the machine base 1 is equipped with a sliding seat 2 that slides left and right along the machine base 1, and the machine base 1 is equipped with a device for driving the sliding seat 2 to slide. Sliding drive device, preferably, the top front of this base 1 is fixed with the front slide rail 11 and the rear slide rail 12 that are co-located below the slide base 2 and extend along the left and right direction of the base 1, the front slide rail 11 and the rear slide rail 12 The slide rails 12 are arranged at relative intervals front and back, and the slide seat 2 is a bar-shaped blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com