A method for cutting aircraft engine blades

An aircraft engine and cutting method technology, applied in electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as blade failure, hidden danger of engine safe use, and surface aluminized layer damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

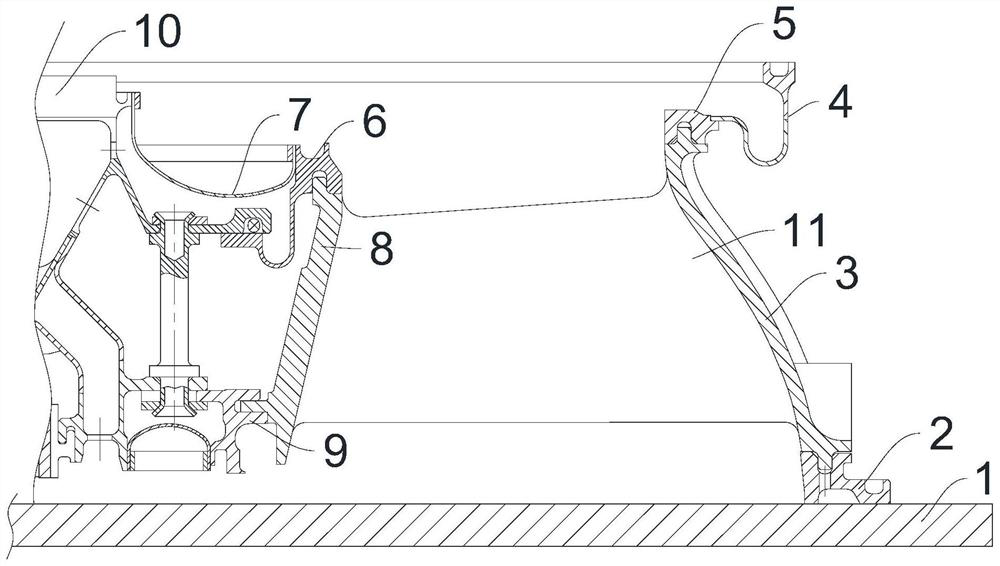

[0040] This cutting method is EDM cutting. The low-pressure turbine guider 10 of the engine is placed horizontally on the EDM equipment platform 1 with the intake side facing upward. The blade is connected to the positive stage of the pulse power supply, and the pulse power supply is loaded between the positive and negative electrodes. When an electric pulse is formed, a spark discharge will be generated between the tip of the copper sheet and the blade, and the central temperature in the discharge channel will reach thousands of degrees instantaneously. The high temperature melts the local metal of the blade to form a thinner slit to achieve the purpose of cutting;

[0041] The specific cutting steps are as follows:

[0042] Step 1: Cut the left and right ends of the lower edge plate 8 of the blade perpendicular to the EDM equipment platform 1 in a direction perpendicular to the upper surface of the EDM equipment platform 1, the distance between the cutting edge and the brazi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com