Single line conveying automatic glue dispensing production line

An automatic glue dispensing and production line technology, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of uneven glue coating, difficult installation and fixation of glass plates, and difficult installation and fixation of glass substrates And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

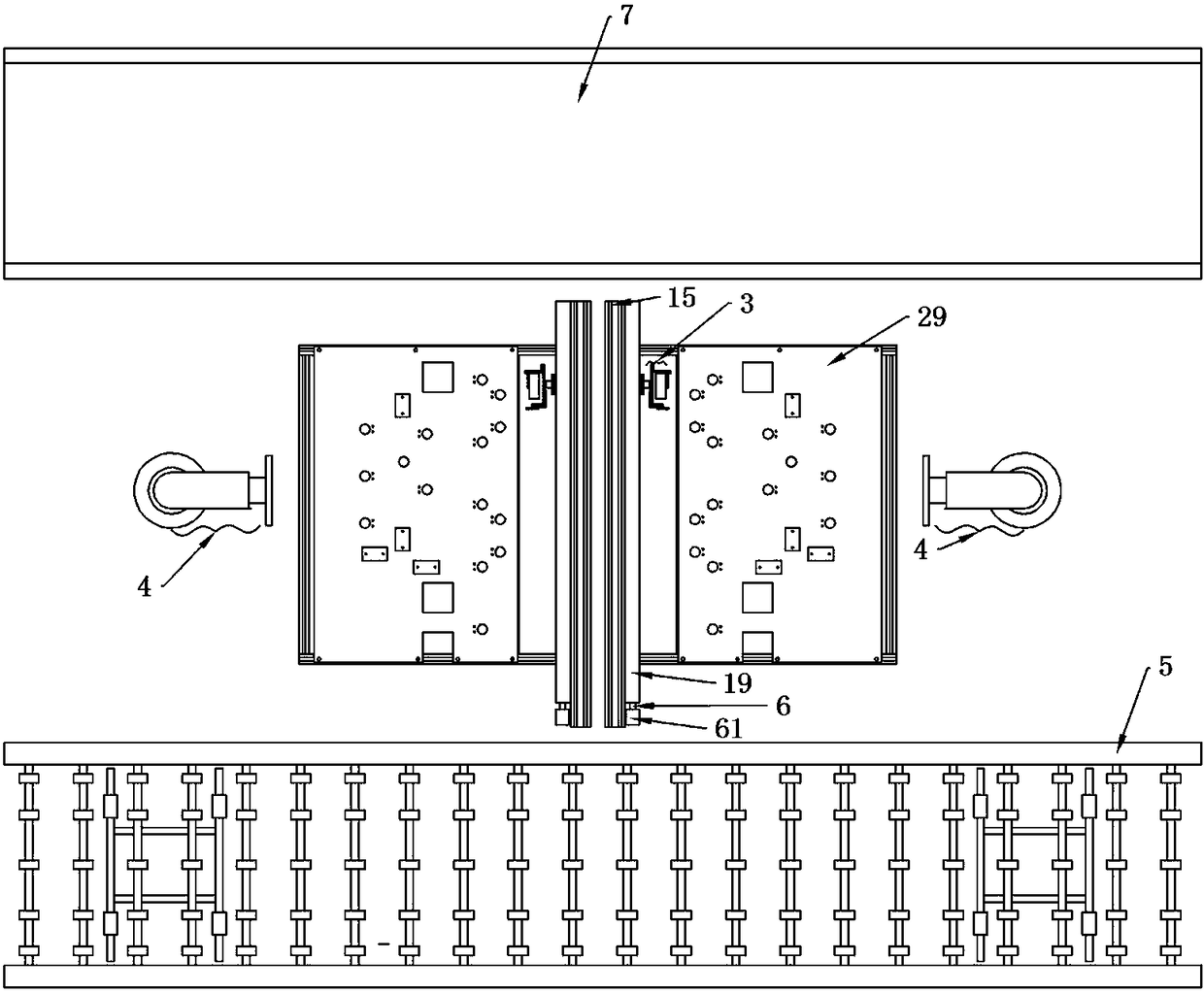

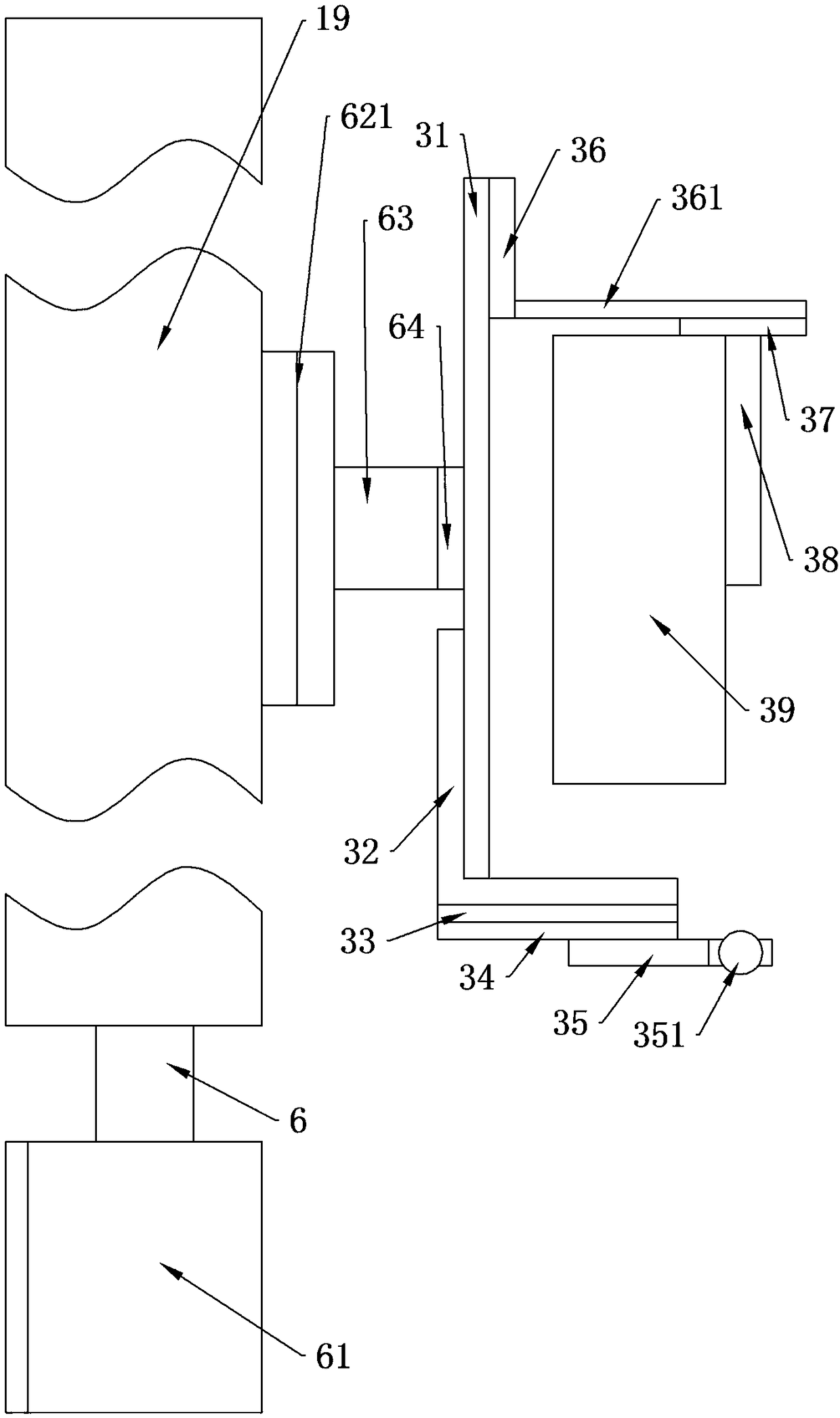

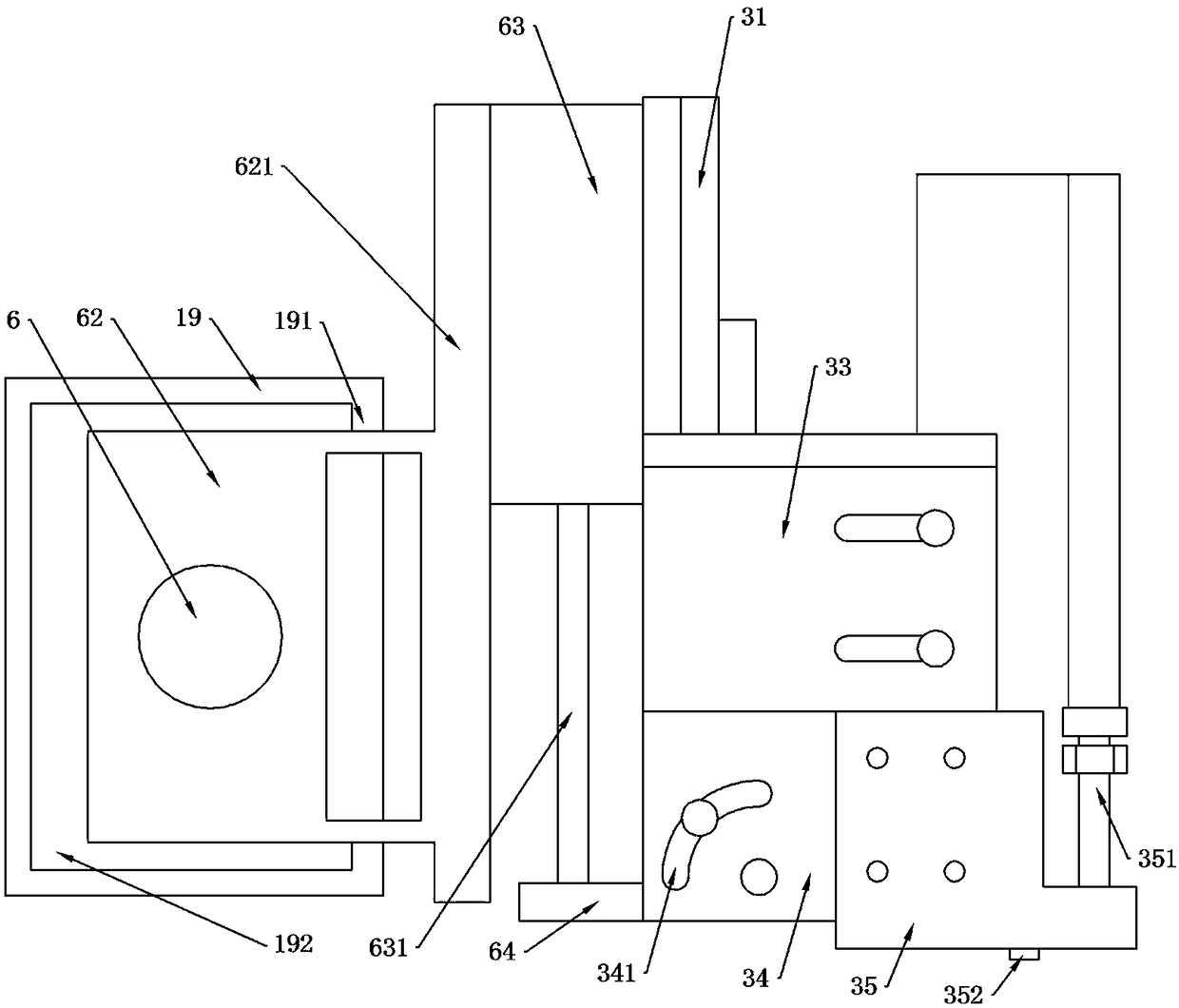

[0043] The specific embodiment of the present invention sees Figure 1-14 :

[0044] An automatic dispensing production line with single-line delivery, such as Figure 1-3 , including two dispensing devices facing away from each other and horizontally side by side, a handling robot 4 is arranged on the left side of the dispensing device on the left side, and a handling robot 4 is also arranged on the right side of the dispensing device on the right side, and the two handling robots The front of the robot 4 is provided with a horizontally arranged feeding conveyor 5, and the rear is provided with a horizontally arranged blanking conveyor belt 7. The feeding conveyor 5 is provided with a plurality of evenly distributed rotating shafts 51 driven by chains. A plurality of evenly distributed rollers 52 are fixed on the rotating shaft 51, and the two side ends of the feeding conveyor frame 5 are provided with lifting frames 8 located below, and the lifting frames 8 include horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com