Sealing mechanism

A sealing and conveyor belt technology, applied in paper/cardboard containers, containers, bag making operations, etc., can solve the problem of easy tearing of the bag body, and achieve the effect of improving quality and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

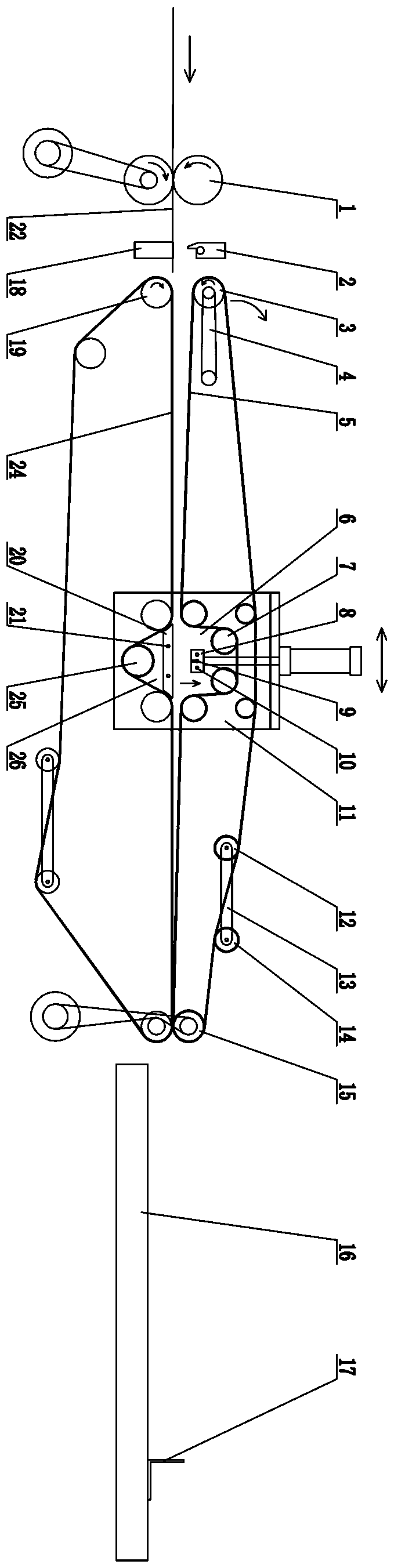

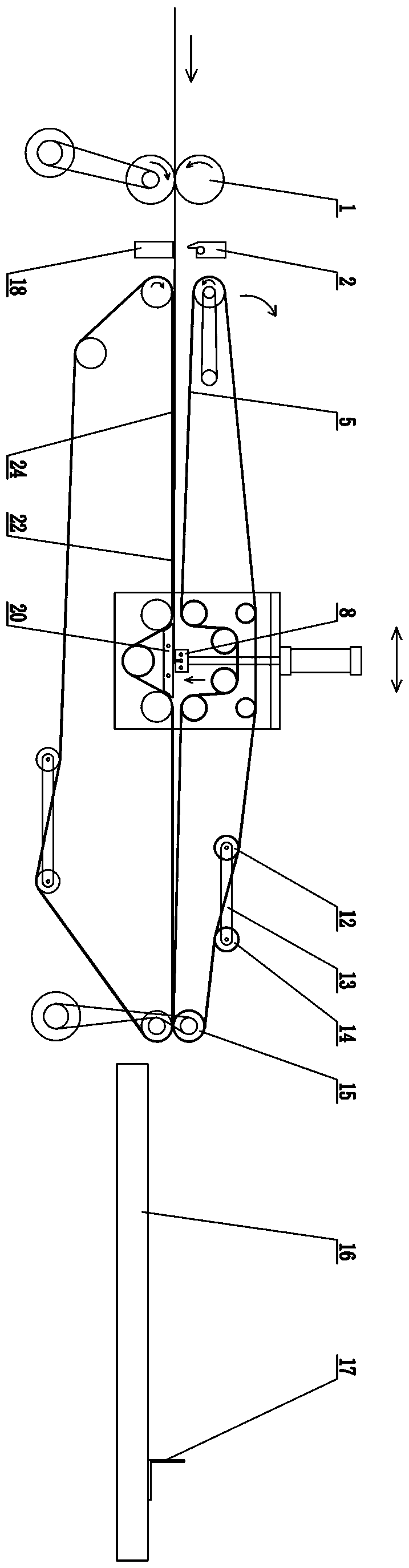

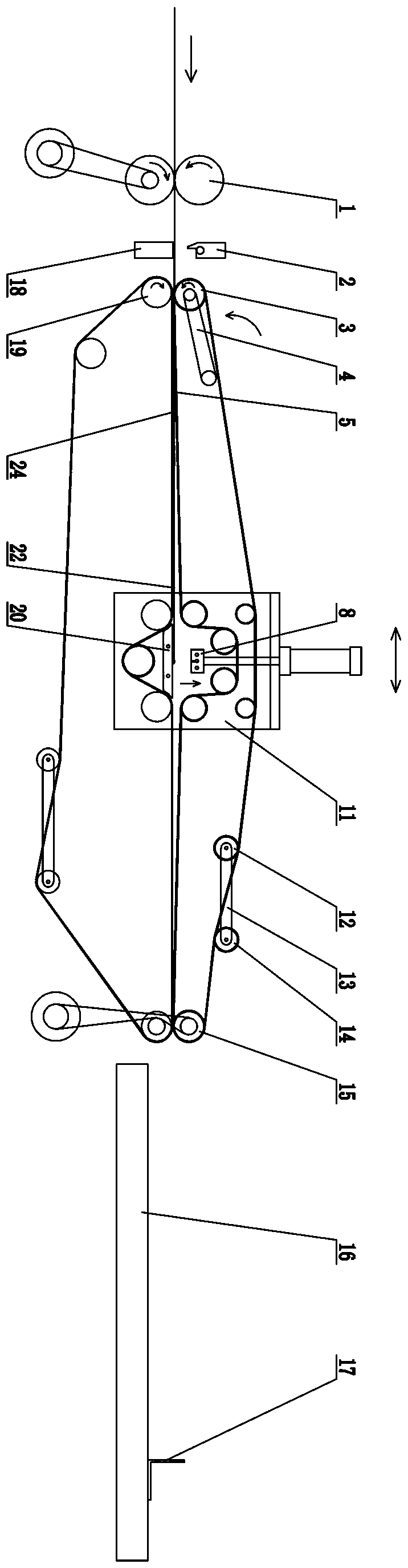

[0020] The details and working principles of the implementation modes and examples of the present invention will be described below with reference to the accompanying drawings. This kind of sealing mechanism includes a sealing and cutting device and a conveying device. A sealing and cooling device is provided in front of the sealing and cutting device. The working positions of the sealing and cutting device and the sealing and cooling device are respectively a sealing and cutting station and a sealing and cooling station; Device is prior art, comprises the sealing cutter 2 that lifts up and down and the following knife 18 that cooperates with sealing cutter, and described sealing cooling device includes upper cooling plate 8; The cooling of the sealing position of bag body on described upper cooling plate can be Air-cooling or water-cooling is used. For thin bags, the effect of air-cooling is better, that is, the upper cooling plate 8 is provided with blowing holes 9, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com