A magnetite beneficiation process for improving coarse-grained tailings content and mill processing capacity

A processing capacity, coarse-grained technology, applied in the field of magnetite beneficiation process, magnetite ore beneficiation process, can solve the problems of increasing operating costs, difficulty in mining and filling balance, difficulty in improving processing capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] First of all, it should be noted that the characteristics and advantages of the magnetite beneficiation process of the present invention will be described in detail below by way of example, but all descriptions are only for illustration, and should not be interpreted as an explanation of the present invention. Invention forms no limitations.

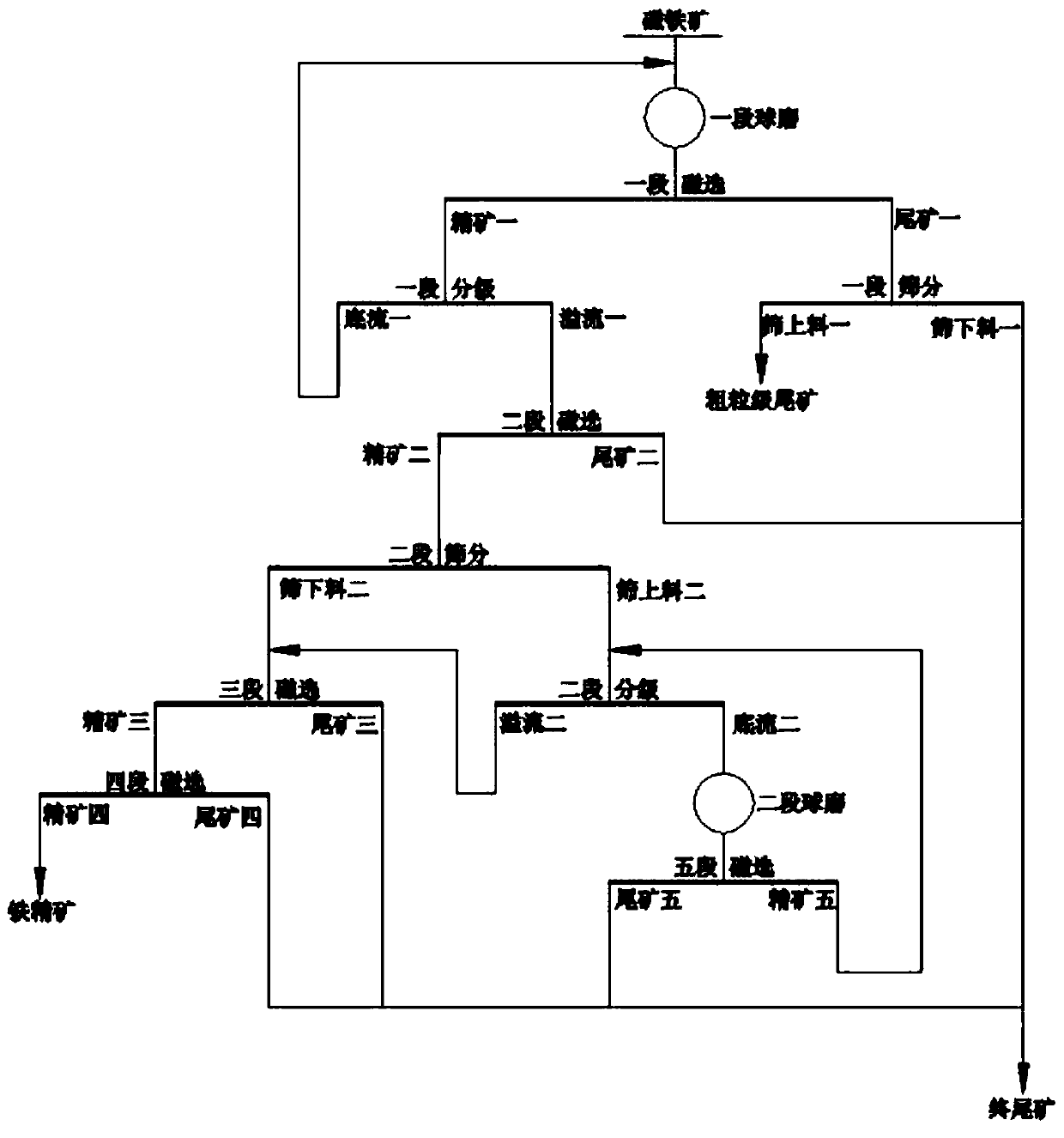

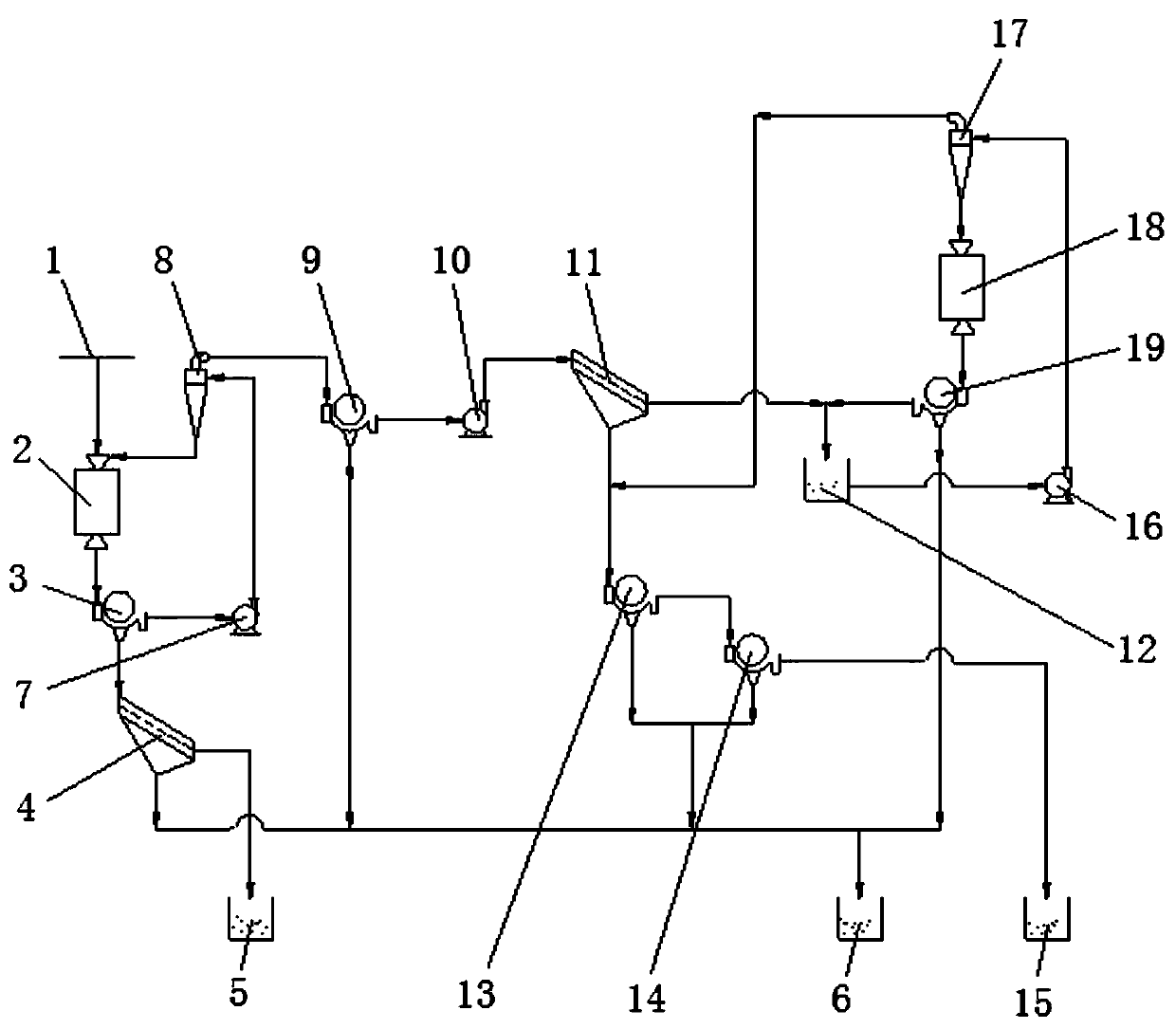

[0018] A magnetite beneficiation plant in Huoqiu, Anhui adopts such figure 1 and figure 2 The beneficiation process shown has an annual ore processing scale of 5 million tons per year. The specific process is as follows: the belt 1 sends the raw magnet ore into the ball mill-2 for a stage of ball milling, and then sends it to the magnetic separator-3 for a stage of magnetic separation to obtain the concentrate 1 and tailings 1; the tailings 1 is sent to the high-frequency fine A section of screening is carried out in the sieve 4 to obtain the upper sieve material 1 and the lower sieve material 1, the upper sieve material 1 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com