A tea oil filtration tank

A filter tank and camellia oil technology, which is applied in the fields of filtration and separation, fixed filter element filter, fat oil/fat refining, etc., can solve the problems of slow filtration of tea oil and difficult discharge of filter residues, so as to improve the passing speed and improve the safety and reliability. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

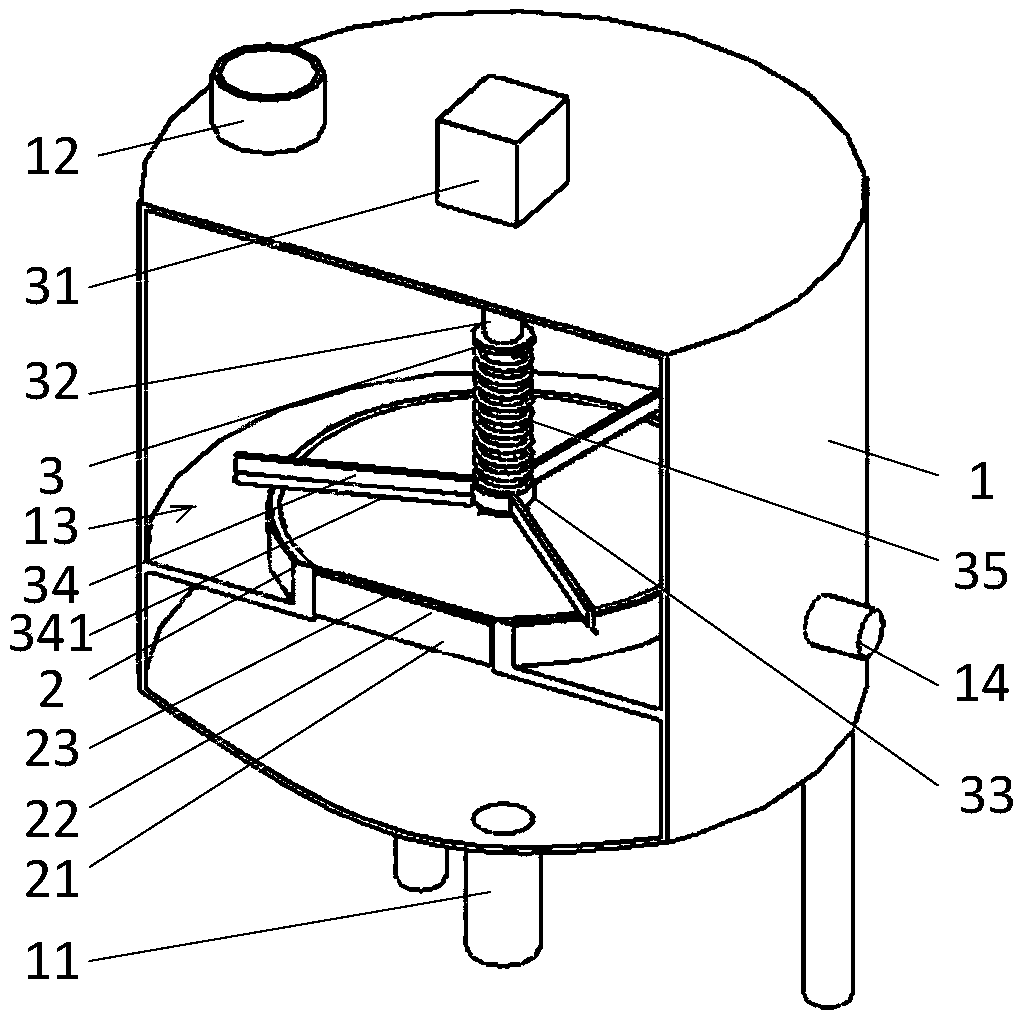

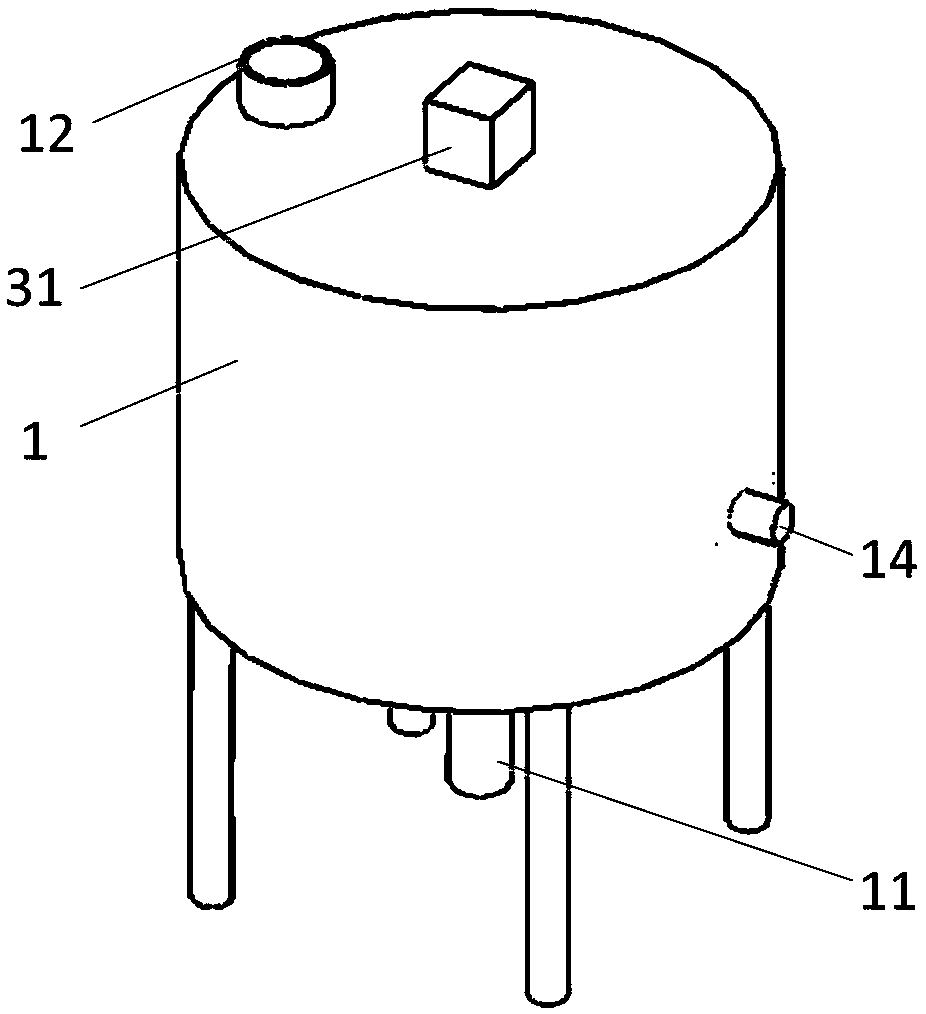

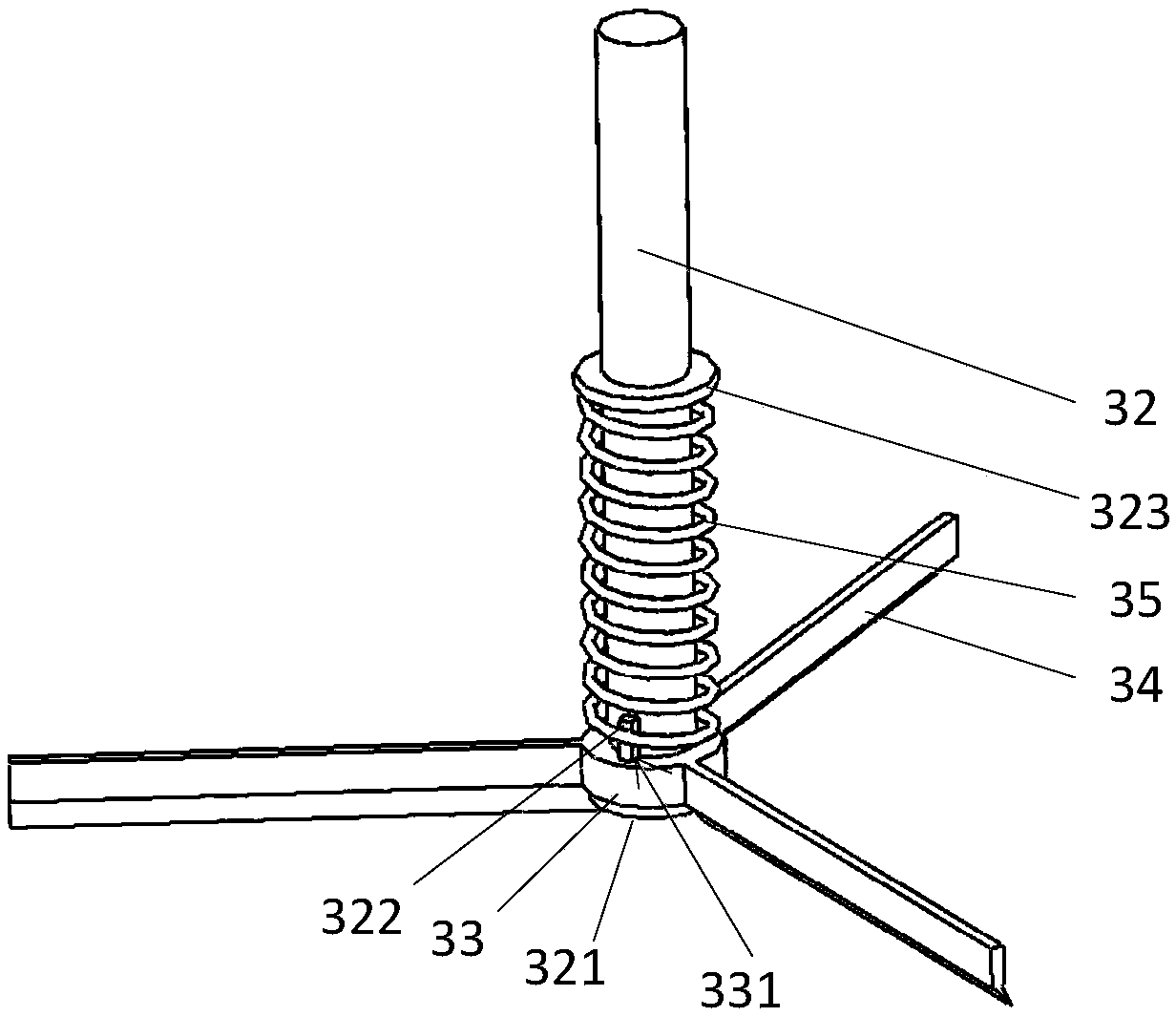

[0024] Such as figure 1 and figure 2 Shown, a kind of camellia oil filter tank, comprises tank body 1, filter layer 2 and net scraping device 3; Wherein:

[0025] The upper part of the tank body 1 is cylindrical, the lower part of the tank body is inverted conical, the lower end of the tank body 1 is provided with an oil outlet 11, and the upper part of the side wall of the tank body 1 is provided with an oil inlet port 12;

[0026] The filter layer 2 is arranged horizontally and the tank body 1 is divided into upper and lower layers; the filter layer 2 is in a circular boss structure, and a filter residue tank 13 is formed between the outer wall of the filter layer 2 circular boss structure and the inner wall of the tank. The outer wall of the tank body 1 is provided with a slag outlet 14 communicating with the bottom of the filter slag tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com