Method and device of utilizing residual heat of charcoal fire for automatically rotating skewers

A technology of automatic rotation and waste heat, which is applied in the direction of baking equipment, applications, household appliances, etc., and can solve the problems of sticky skewers, burnt grillers, and undercooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

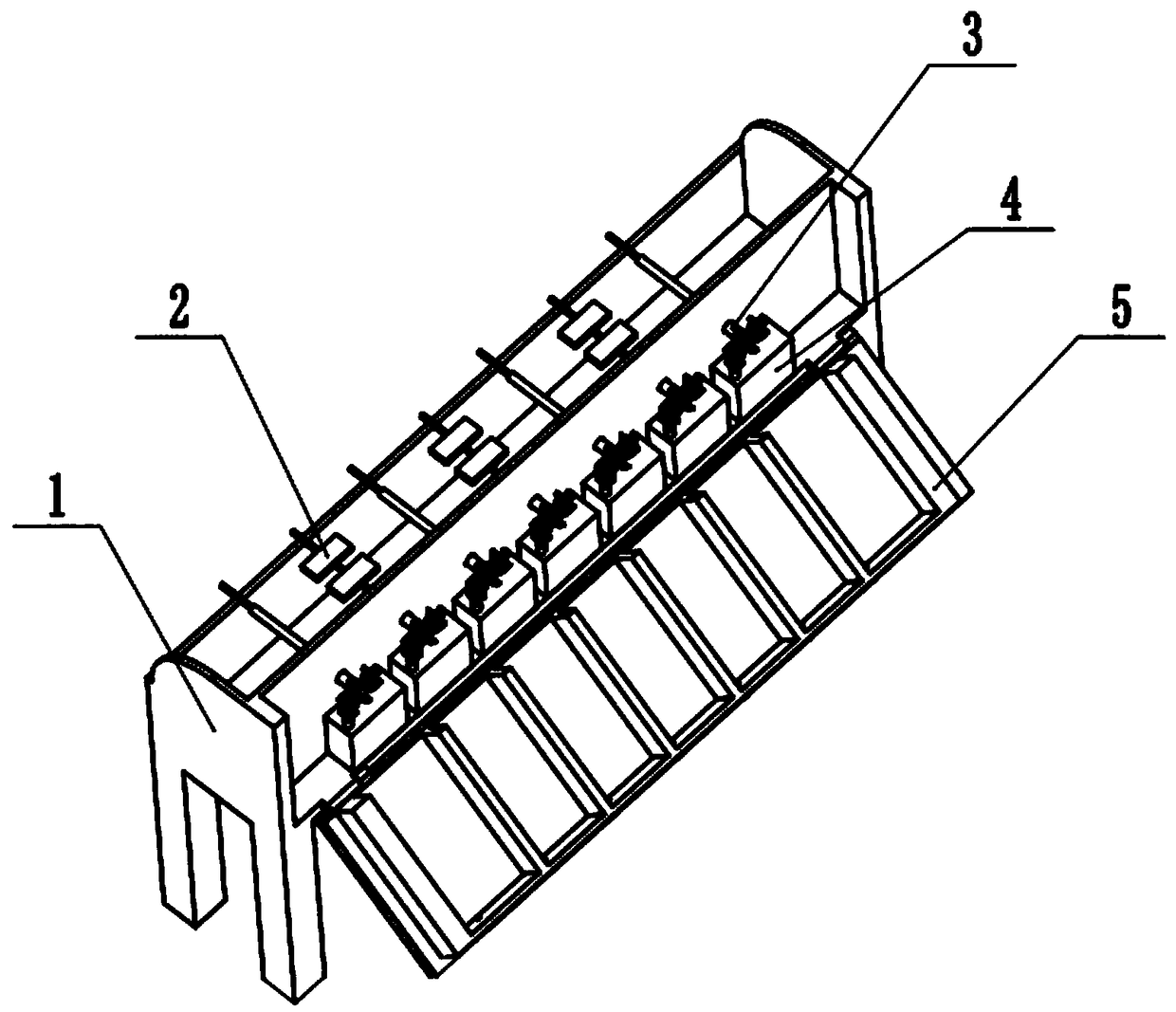

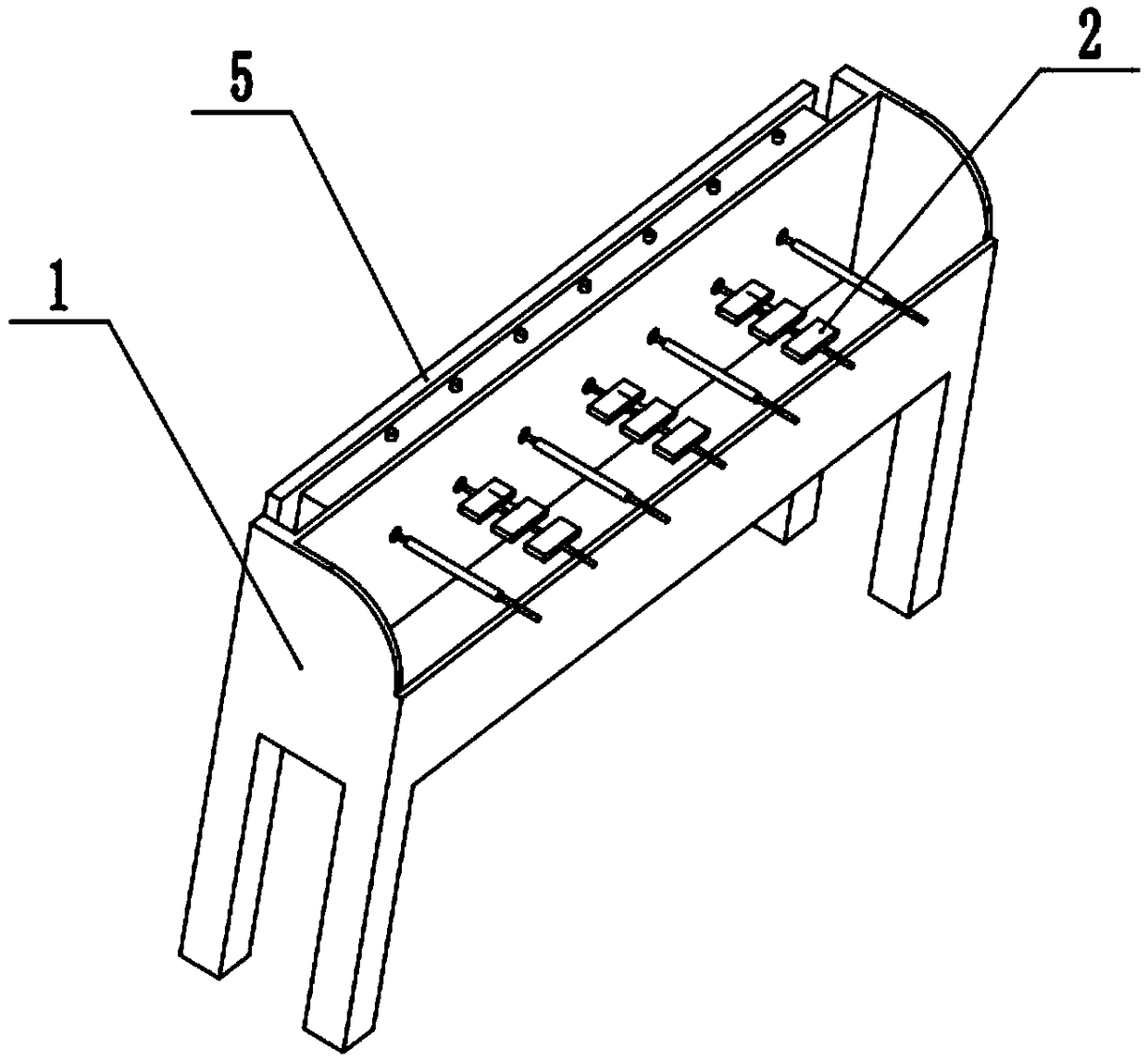

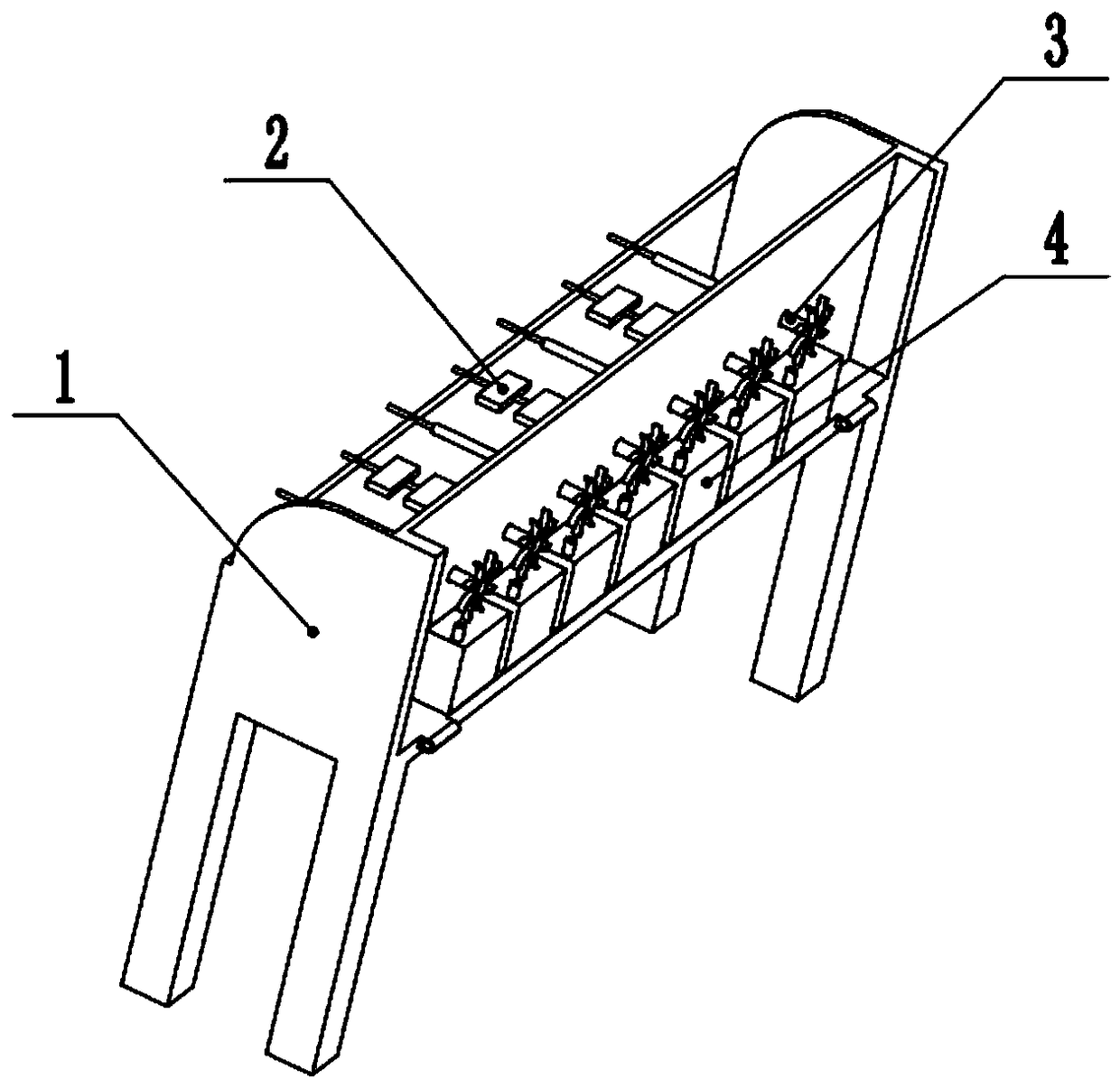

[0022] A method capable of utilizing residual heat of a charcoal fire to automatically rotate barbecue, comprising a grill 1, a skewer 2, an impeller 3, a flat water tank 4 and a rear baffle 5, characterized in that it includes the following steps:

[0023] (1) The top of the grill 1 has a charcoal slot 101, charcoal can be placed in the charcoal slot 101, the front edge of the charcoal slot 101 is evenly provided with a skewer placement slot 103, and the rear wall of the charcoal slot 103 is evenly distributed with The impeller installation hole 102, the skewer 2 is placed in the skewer placement groove 103, the impeller 3 is installed in the impeller installation hole 102, the top of the skewer 2 can be inserted into the end face of the impeller shaft, and the flat water tank 4 is arranged in the charcoal groove 103 rear wall, the upper part of the flat water tank 4 is provided with an air outlet 401, the flat water tank 4 can absorb the residual heat of the charcoal fire, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com