Flexible strip weaving sofa

A technology for flexible strips and sofas, applied in the sofa field, can solve the problems of inability to realize assembly line production, low production efficiency, inability to realize mechanized production, etc., and achieve the effect of facilitating mechanical weaving and assembly line operations and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Example 1: Flexible Strip Weaving Sofa

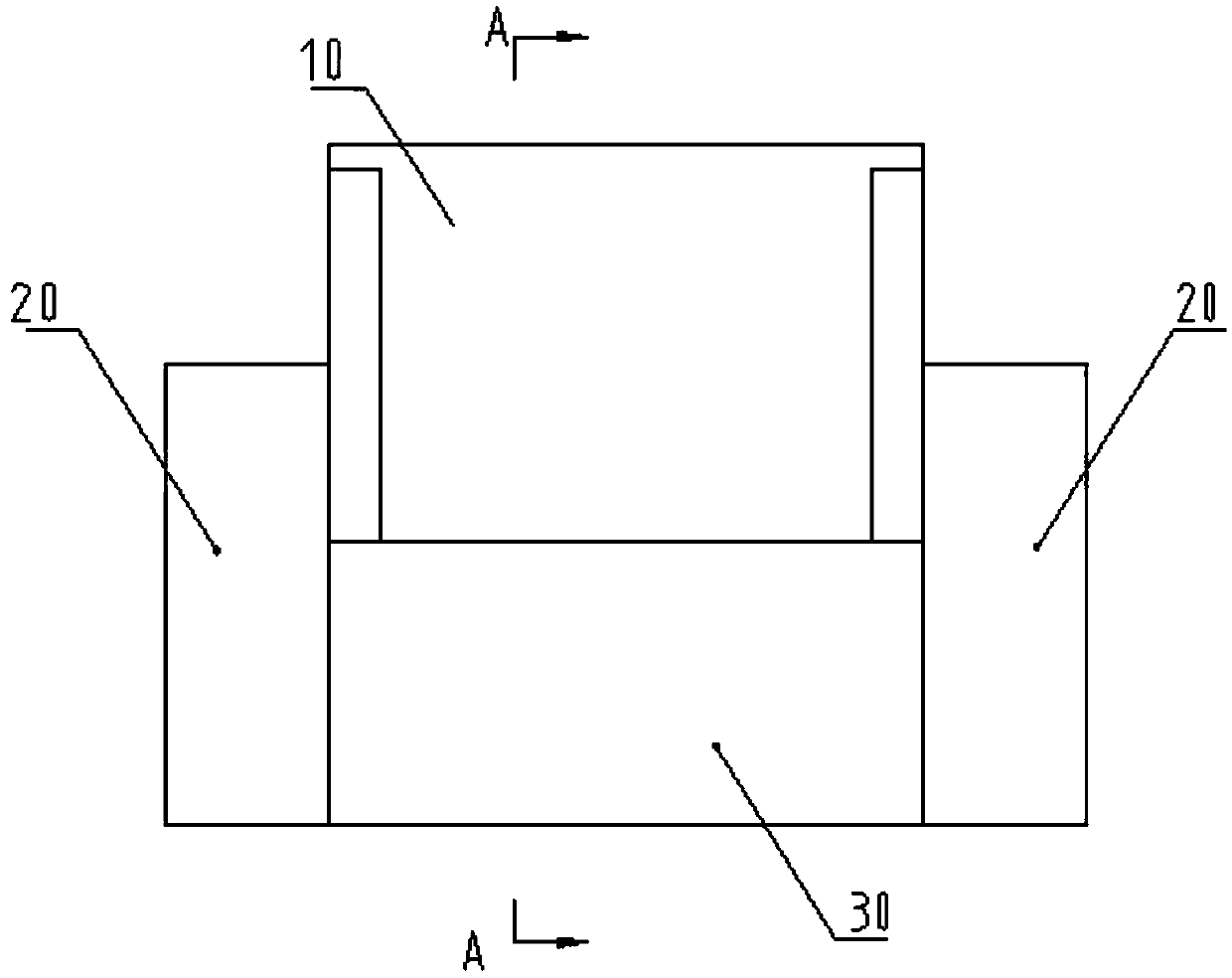

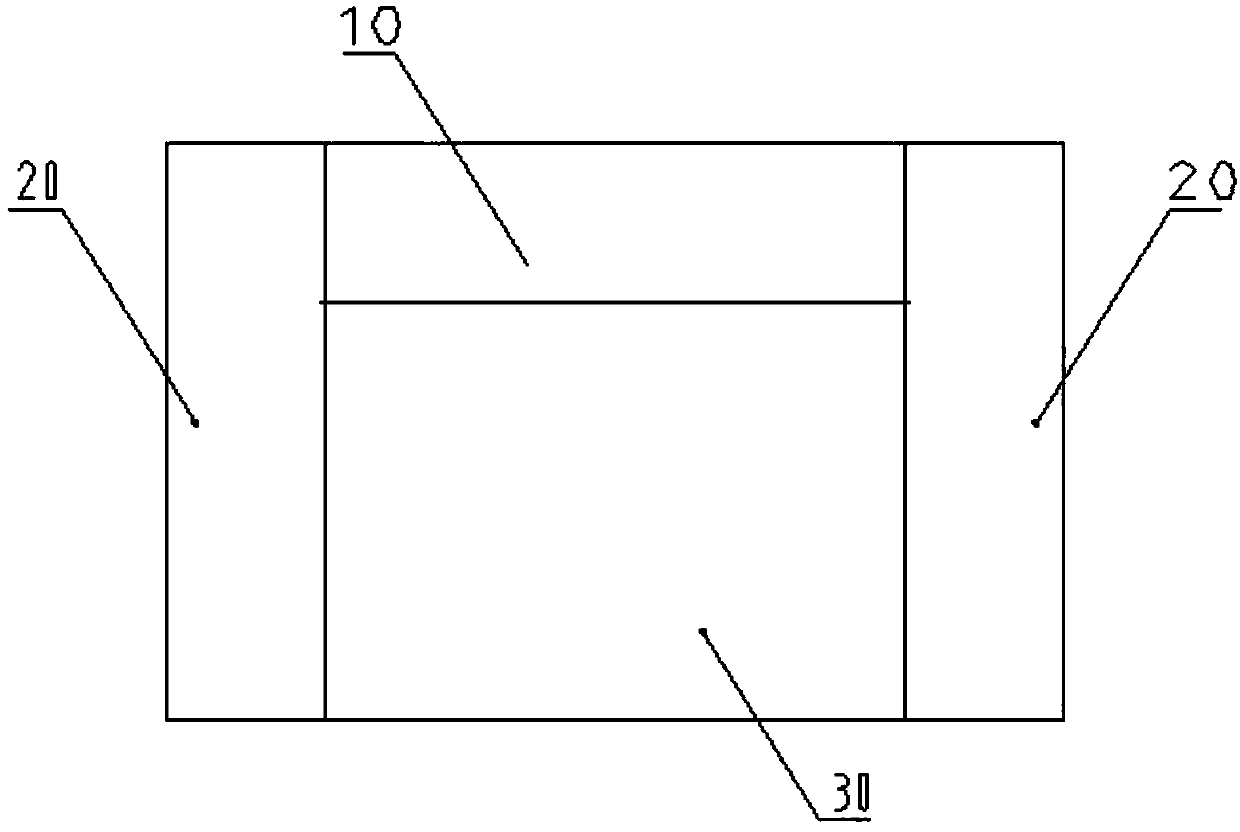

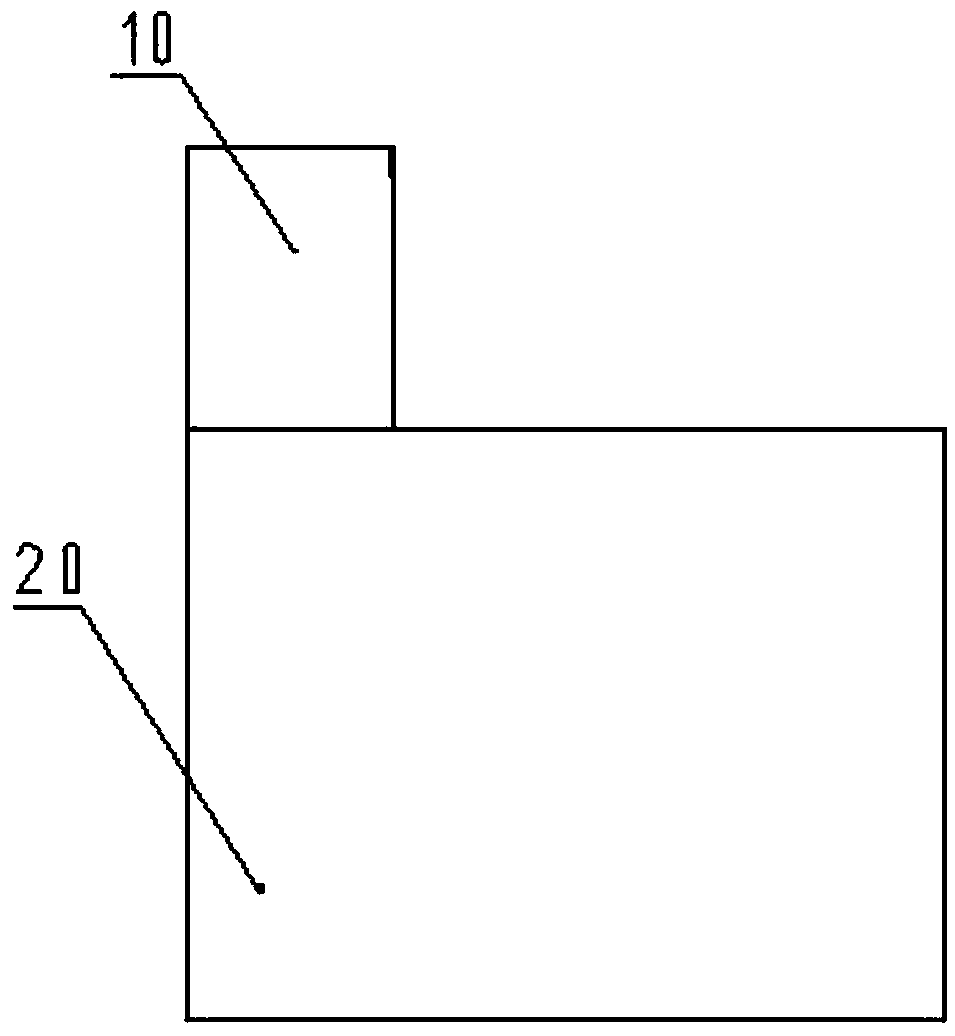

[0099] attached Figure 1-5 The shown flexible strip woven sofa is an individual flexible strip woven sofa (in other embodiments, it can be a combined sofa composed of more than 2 individual flexible strip woven sofas); the individual flexible strip woven sofa is composed of a backboard 10, The side plate 20 and the base 30 are composed of (in other embodiments, other components may also be included), the back plate 10 is connected to the rear end of the base 30, the side plate 20 is connected to the side of the base 30, and is respectively arranged on both sides of the base 30. A side plate 20 (in other embodiments, the side plate 20 may only be provided on one side of the base 30).

[0100] The backboard 10, side panels 20, and base 30 are all composed of flexible strip woven panel units (in other embodiments, at least one of the backplane 10, side panels 20, and base 30 is composed of flexible strip woven panel units), The f...

Embodiment 2

[0122] Embodiment 2: The frame assembly is a flexible strip braided panel unit of a planar frame member, and no tendons are arranged in the middle of the frame.

[0123] attached Figure 50-55 The frame assembly shown is a flexible strip braided panel unit of a planar frame member, including a flexible strip braided panel 1, a frame assembly 2, a splint 3, and a rivet 4; the flexible strip braided panel 1 is woven by several flexible strips 1.1. It can be formed into a planar shape. In this embodiment, the flexible strip 1.1 is a rattan imitation.

[0124] The frame assembly 2 is a first planar frame member, which is a closed rectangular frame member surrounded by 4 straight bars 2.1 (in other embodiments, the frame assembly of the first planar frame member is more than 3 straight bars in one Enclosed in the plane, the shape is rectangular or shaped closed or open frame structure). In this embodiment, the straight rod 2.1 is a hollow pipe with a rectangular cross-section (...

Embodiment 3

[0131] Embodiment 3: The frame assembly is a flexible strip woven sofa of a plane frame member, and ribs are arranged in the middle of the frame.

[0132] attached Figures 56-61 The frame assembly shown is a flexible strip woven sofa of a plane frame member, including a flexible strip woven panel 1, a frame assembly 2, a splint 3, and screws 4; the flexible strip woven panel 1 is woven by several flexible strips 1.1, and can be To form a planar shape, in this embodiment, the flexible strip 1.1 is a rubber strip.

[0133] The frame assembly 2 is a second planar frame member, which is a closed rectangular frame member surrounded by 4 straight bars 2.1 (in other embodiments, the frame assembly of the second planar frame member is more than 3 straight bars in one Enclosed in the plane, the shape is rectangular or Shaped closed or open frame structure), the middle of the frame is provided with ribs 2.2 (in this embodiment, 3 ribs 2.2 are cross-shaped, in other embodiments, one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com