Distributed battery winding independent power supply multi-phase motor driving system and method

A multi-phase motor, independent power supply technology, applied in the control system, AC motor control, electrical components and other directions, can solve the problems of insurmountable, inability to exert high reliability of multi-phase motors, increase circuit complexity, etc., to achieve low cost, Heat dissipation problem solving, strong adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

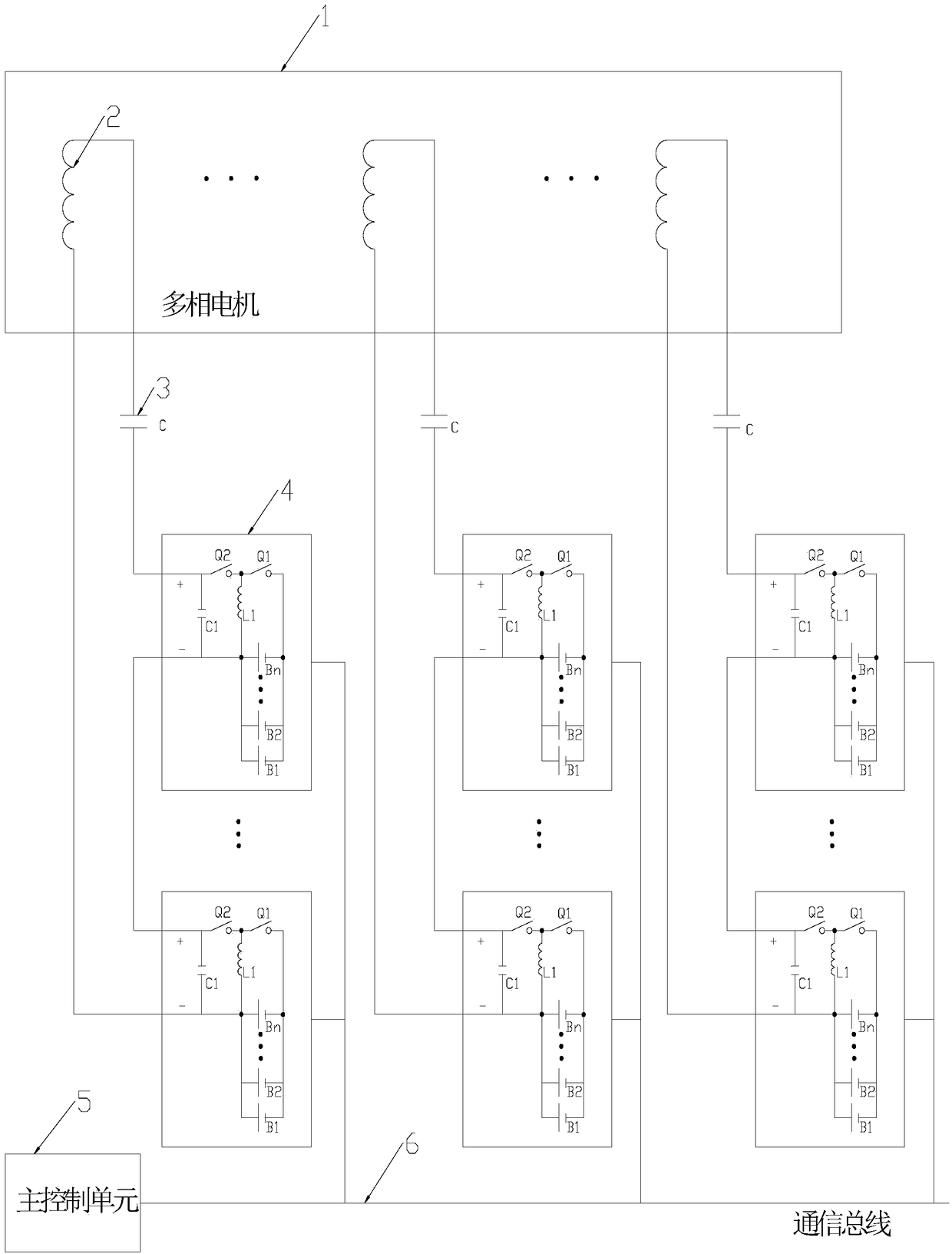

[0034] Such as figure 1 As shown, a multi-phase motor drive system in which the windings of the distributed battery pack are independently powered, the multi-phase motor 1 includes multi-phase windings, and each phase winding 2 is connected to a power supply unit separately, and all the power supply units are connected to the main control unit 5 through the communication bus 6;

[0035] The power supply unit includes a battery pack voltage conversion module 4, the anode of the battery pack voltage conversion module 4 is connected to a capacitor C3 and then connected to one end of the winding;

[0036] The negative electrode of the battery pack voltage conversion module 4 is connected to the other end of the winding;

[0037] The battery pack voltage conversion module 4 outputs a sinusoidal voltage waveform with a voltage offset, and outputs a standard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com