A novel pressure relief device for high-voltage switch cabinet

A high-voltage switchgear and pressure relief device technology, applied in the direction of switchgear, switchgear setting, substation/switchgear cooling/ventilation, etc., can solve the problems of switchgear accidents, surrounding equipment and staff injuries, etc., to achieve The effect of reducing the internal pressure of the cabinet and increasing the ventilation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

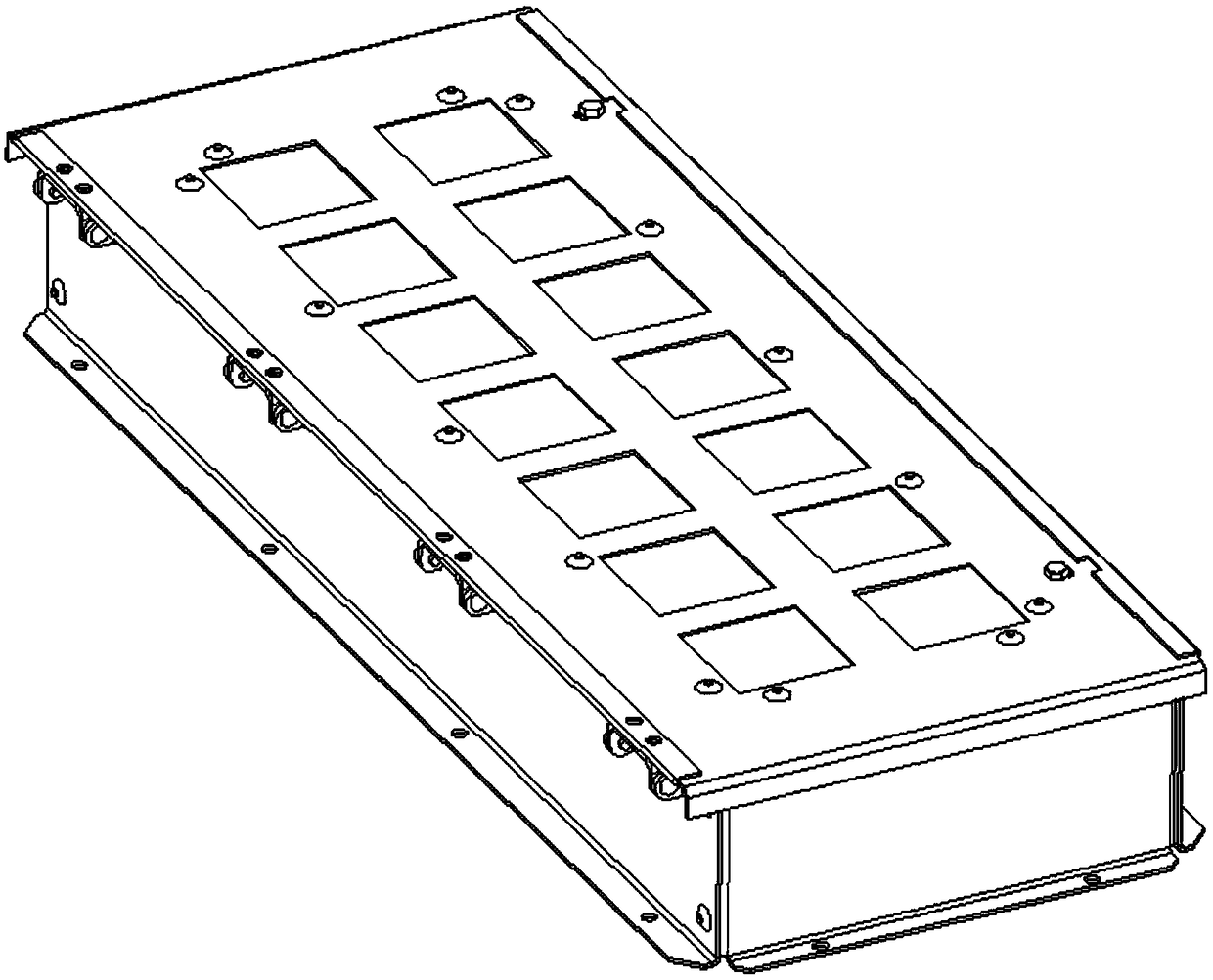

[0038] Such as Figures 1 to 4 As shown, a novel pressure relief device for a high-voltage switchgear includes a box body 1 with a rectangular parallelepiped structure. The box body 1 has an opening formed on a larger surface and a pressure relief valve detachably covered at the opening. Cover plate 5, fish scale explosion-proof plate 4 is installed on the inboard of pressure relief cover plate 5, and several filter screens 8 are fixed side by side in casing 1. When the pressure in the cabinet reaches a certain value, the pressure relief cover plate 5 is washed away under the pressure in the cabinet to achieve the purpose of pressure relief. On the one hand, the fish scale explosion-proof plate 4 can meet the requirements of IP4X protection level, on the other hand, it can meet the heat dissipation requirements of the cabinet.

[0039] The filter screen 8 is made of integral sheet metal, and it has two bending parts 81 bent inwardly with its center line as the bending line. T...

Embodiment 2

[0046] Such as Figure 5 As shown, the difference from Embodiment 1 is that in this embodiment, the filter screen 8 has two bending parts 84 that are formed by bending inwardly with two parallel lines as the bending lines and maintain two parallel lines. Between the body 83 of the original shape. When fixing, the main body 83 is fixedly connected with the beam 3 , and the bottom edge of the bent portion 84 is fixedly connected with the slot of the longitudinal beam 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com