Measuring system for radial deformation of nuclear fuel cladding tube under high temperature iodine vapor environment

A radial deformation and measurement system technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems that the iodine vapor environment cannot be simulated, and the high-precision real-time measurement of the deformation of the cladding tube cannot be achieved, and the installation is simple and the cost is low. Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

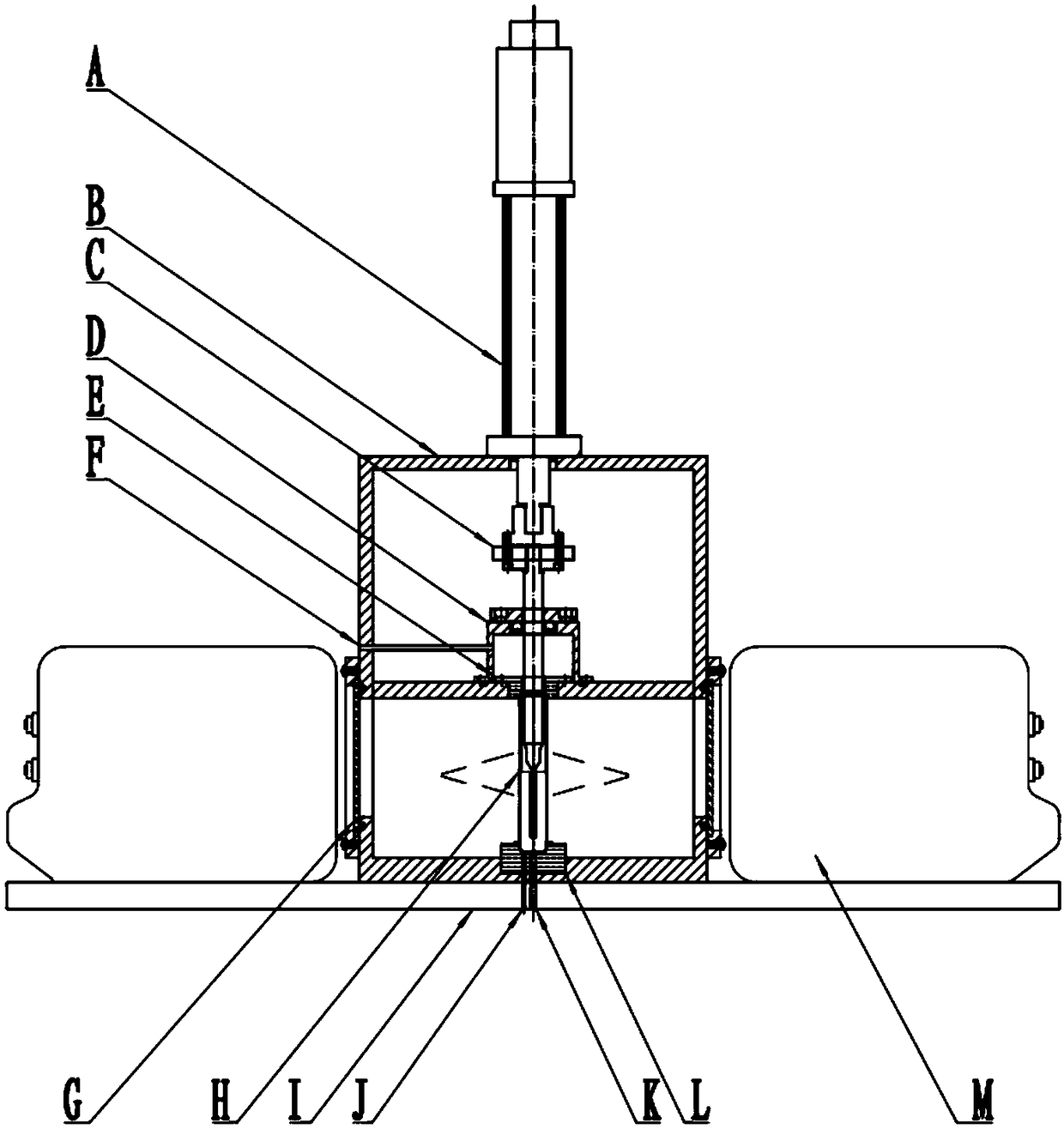

[0023] Such as figure 1 As shown, the radial deformation measurement system of a nuclear fuel cladding tube under a high-temperature iodine vapor environment of the present invention is characterized in that: it comprises a nuclear fuel cladding tube H, a base I, a double-layer heat chamber B installed on the base I, a double-layer The heat chamber B is divided into an upper layer and a lower layer by the interlayer installed on the top of the cladding tube H, and the sealing cover E installed on the top of the cladding tube H and the upper part of the interlayer center in the double-layer heat chamber B is installed on The bottom of the cladding tube H and the sealed base L installed in the bottom center of the double-layer heat chamber B, the cylindrical chamber D installed on the upper layer of the double-layer heat chamber B and communicated with the clad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com