Independently mounted hydrodynamic retarder

A hydraulic retarder and ventilation device technology, applied in the direction of liquid resistance brakes, slack adjusters, brake types, etc., can solve the problems of air leakage into the working chamber and affect the work of the hydraulic retarder, and reduce the number of replacements. The effect of oil frequency, light weight, and increased usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

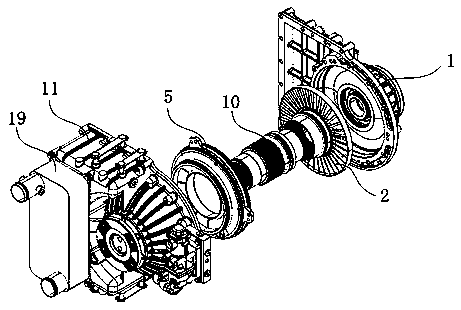

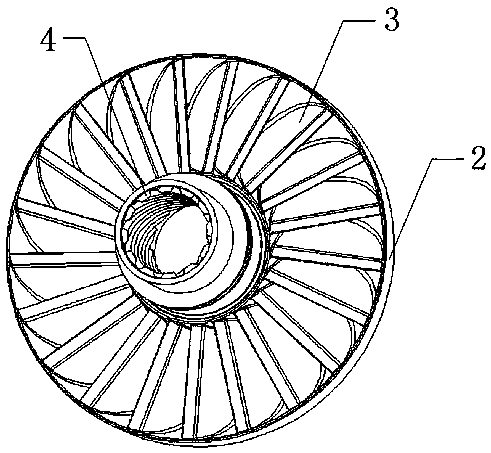

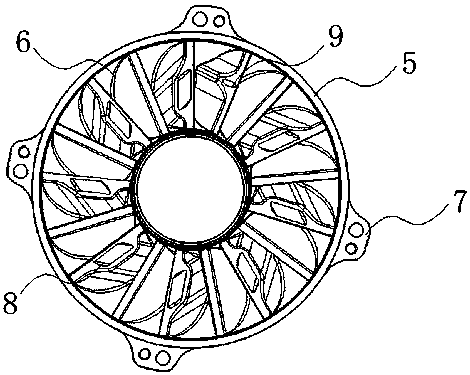

[0026] Such as Figure 1-6 As shown, the present invention discloses an independently installed hydraulic retarder, including a hydraulic retarder cover 1, a rotor pump driving wheel, a stator pump resistance wheel, a spline shaft 10, and a hydraulic retarder housing 11 , electromagnetic proportional valve 18 and heat exchanger 19, hydraulic retarder adopts hemispherical design, hydraulic retarder housing 11 includes working chamber 12 and oil storage chamber 13, hydraulic retarder cover 1 and hydraulic The retarder shells 11 are matched with each other and connected and fixed by fixing bolts. The stator pump resistance wheel is set in the working chamber 12 of the hydraulic retarder shell 11, and the rotor pump driving wheel is set in the hydraulic retarder cover 1. The key shaft 10 is arranged between the rotor pump driving wheel and the stator pump resisting wheel, and is driven to rotate by the thread structure. The ventilation device 16 is connected with the exhaust hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com