Antibacterial non-woven fabric with high barrier performance and preparation method thereof

A non-woven, high-barrier technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of poor antibacterial effect and poor barrier performance of non-woven fabrics, and achieve excellent processing and molding performance, stable size, and difficult The effect of peel-off coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the above-mentioned antibacterial non-woven fabric with high barrier performance comprises the following steps:

[0029] S1 prepares the non-woven fabric layer: prepare non-woven fabric raw materials according to parts by weight: 50-60 parts of low-density polyethylene, 6-8 parts of polypropylene, 6-8 parts of polyisobutylene and 10-15 parts of reinforcement modifier, will have no The textile raw materials are put into the spinning machine, and the non-woven fibers are obtained through hot-melt high-pressure extrusion, spinning, air cooling, stretching, soaking, secondary stretching, drying, and cutting. Add fiber opener for opening, use fiber carding machine to process the above-mentioned opened non-woven fabric fibers into uniform, continuous and stable fibers, and use hot air dryer to use stable and continuous high-temperature hot air flow to process the above-mentioned fibers Continuous processing, so that the skin layer of the fiber in the...

Embodiment 1

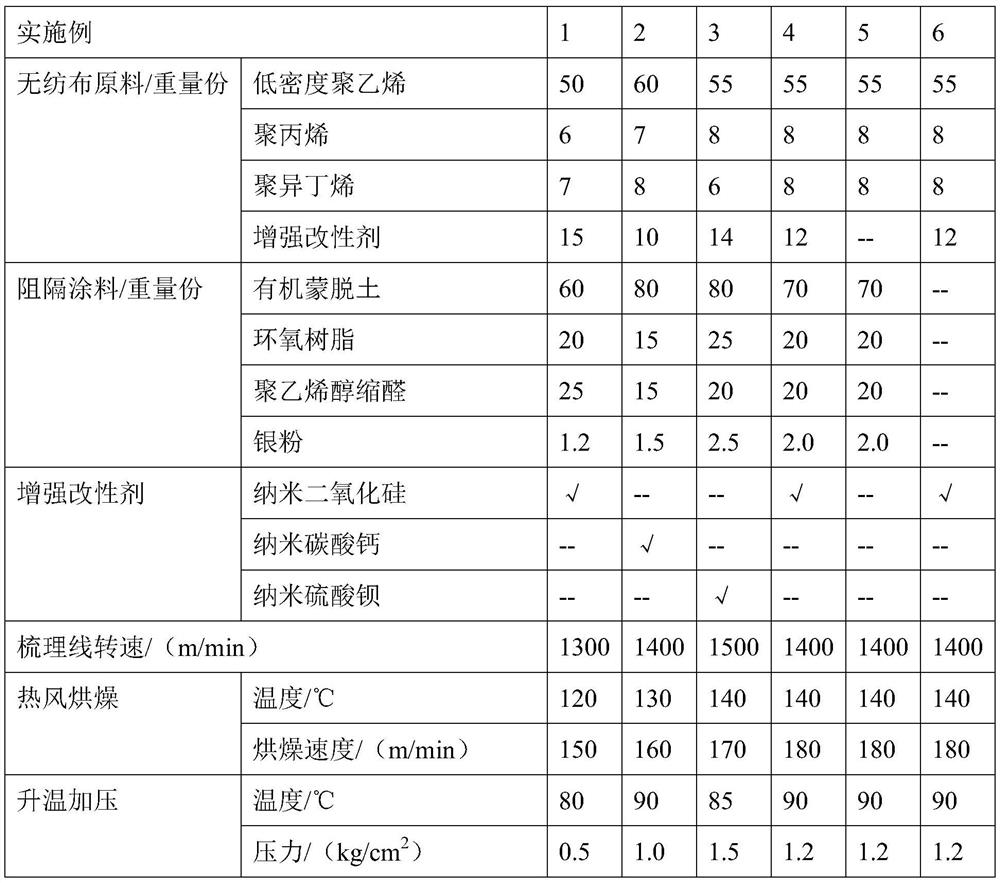

[0033] The specific preparation method of embodiment 1-embodiment 6 is as shown in table 1, wherein embodiment 1-embodiment 4 is the technical parameter that the present invention limits, does not contain strengthening modifier in embodiment 5, does not set in embodiment 6 Barrier coating, wherein embodiment 5-embodiment 6 is the comparative example of the present invention.

[0034] The concrete preparation method of table 1 embodiment 1-embodiment 6

[0035]

[0036] The concrete performance parameter of the nonwoven fabric that embodiment 1-embodiment 6 makes is as shown in table 2, and wherein embodiment 1-embodiment 4 is the technical parameter that the present invention limits, does not contain strengthening modifier in embodiment 5, Barrier coating is not provided in embodiment 6, wherein

[0037] Embodiment 5-Example 6 are comparative examples of the present invention.

[0038] The hydrostatic pressure is tested with a hydrostatic pressure tester;

[0039] The to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com