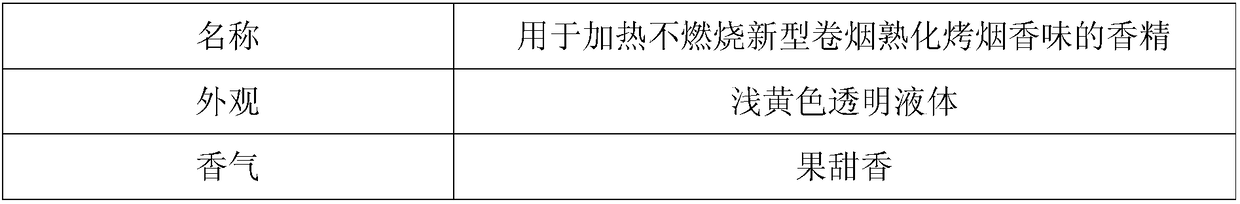

Cured flue-cured tobacco flavored essence for heating non-burning cigarette as well as preparation method and application thereof

A heat-not-burn and cigarette technology, which is applied in applications, essential oils/fragrances, tobacco, etc., can solve the problems of not being designed, and achieve the effects of good satisfaction, promoting cell regeneration, and comfortable fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

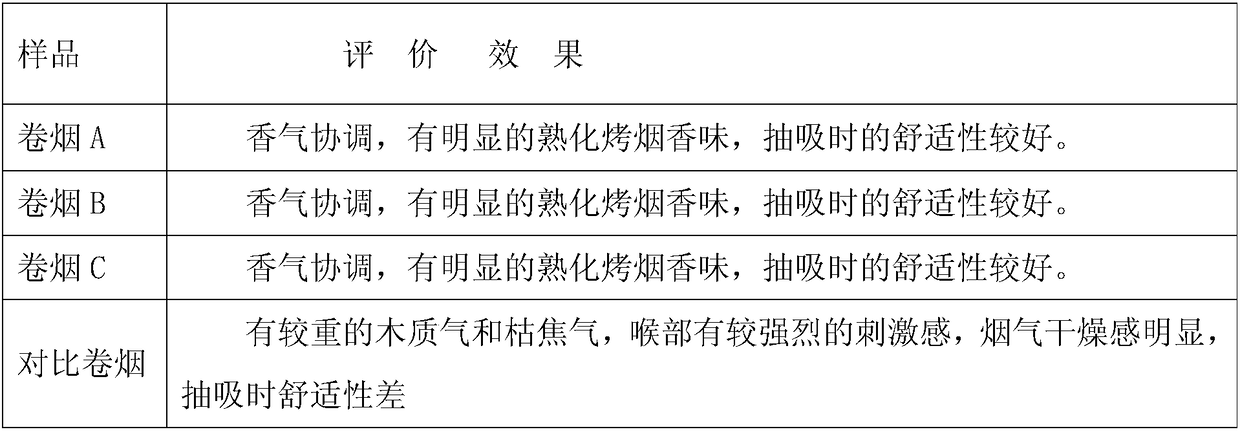

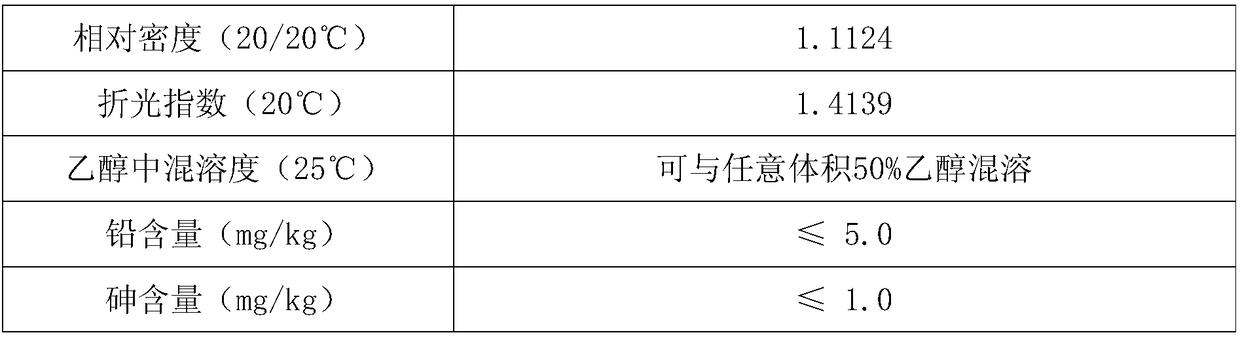

[0039] Example 1: A cured flue-cured tobacco aroma and flavor used in heat-not-burn cigarettes, the specific preparation steps are as follows: 42.53 parts of ethanol, 0.05 parts of fennel oil, 0.3 parts of chamomile oil, and 0.4 parts of ethyl maltol in the raw materials , 0.008 parts of guaiacol, 0.2 parts of 5-methylfurfural, 0.005 parts of 2-acetylpyrazine, 0.007 parts of 2,3-dimethylpyrazine, 3.5 parts of special Yunyan essential oil, 3.0 parts of special Virginia tobacco leaf essential oil, Add 50 parts of glycerin into the stirring container in order, mix and stir for 2-4 hours, stand still for 24-48 hours, use a filter membrane with a pore size of 0.8 microns to filter out the sediment and obtain a filtrate with a relative density of 1.05-1.25. Flavor used for the aroma of cured flue-cured tobacco in heat-not-burn new cigarettes.

[0040] The essence prepared in Example 1 for the aroma of cured flue-cured tobacco in heat-not-burn cigarettes was diluted 6 times with 70% ...

Embodiment 2

[0041] Example 2, an essence for the aroma of cured flue-cured tobacco in heat-not-burn cigarettes, the specific steps are as follows: 45.658 parts of ethanol, 0.03 parts of fennel oil, 0.2 parts of chamomile oil, 0.8 parts of ethyl maltol, 0.004 parts of guaiacol, 0.3 parts of 5-methylfurfural, 0.004 parts of 2-acetylpyrazine, 0.004 parts of 2,3-dimethylpyrazine, 4 parts of special Yunyan essential oil, 4 parts of special Virginia tobacco leaf essential oil, glycerin 45 parts, put into the stirring container in order, stir for 2-4 hours after mixing, stand still for 24-48 hours, use a filter membrane with a pore size of 0.8 micron to filter out the sediment to obtain a filtrate with a relative density of 1.05-1.25, which is the used It is an essence for the aroma of cured flue-cured tobacco in heat-not-burn new cigarettes.

[0042] Dilute the cured flue-cured tobacco flavor essence prepared in Example 2 and used in heat-not-burn cigarettes by 6 times with 70% ethanol, spray i...

Embodiment 3

[0043] Example 3, an essence for the aroma of cured flue-cured tobacco of a new type of heat-not-burn cigarette. The specific steps are as follows: 41.766 parts of ethanol, 0.02 parts of fennel oil, 0.1 part of chamomile oil, 0.7 parts of ethyl maltol, 0.002 parts of guaiacol, 0.4 parts of 5-methylfurfural, 0.006 parts of 2-acetylpyrazine, 0.006 parts of 2,3-dimethylpyrazine, 2.5 parts of special Yunyan essential oil, 4.5 parts of special Virginia tobacco leaf essential oil, glycerin 50 parts, put into the stirring container in order, stir for 2-4 hours after mixing, stand still for 24-48 hours, use a filter membrane with a pore size of 0.8 micron to filter out the sediment to obtain a filtrate with a relative density of 1.05-1.25, which is the used It is an essence for the aroma of cured flue-cured tobacco in heat-not-burn new cigarettes.

[0044] Dilute the cured flue-cured tobacco flavor essence prepared in Example 3 and used in heat-not-burn cigarettes by 6 times with 70% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com