Regenerated water making system and method

A technology for preparing system and reclaiming water, which is applied in water treatment parameter control, chemical instruments and methods, water/sewage treatment equipment, etc. The effect of improving economic and environmental benefits, reducing the efflux of reclaimed water, and improving the rate of reclaimed water reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

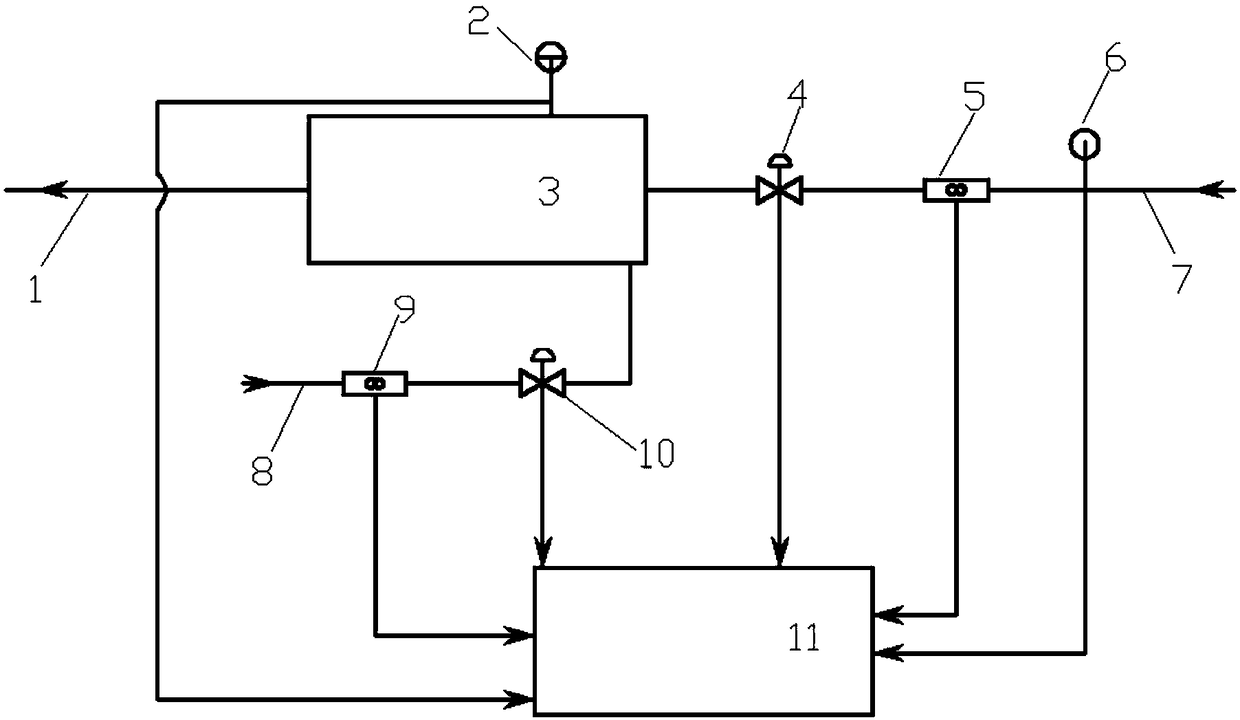

[0039] See attached figure 1 , this example provides a reclaimed water preparation system, including: reclaimed water suction well 3, reclaimed water supply pipe 7, desalted water supply pipe 8, reclaimed water differential pressure flowmeter 5, reclaimed water regulating valve 4, desalted salted water differential pressure flowmeter 9 and desalted water regulating valve 10, wherein:

[0040] The reclaimed water supply pipe 7 and the desalted water supply pipe 8 are connected to the input end of the reclaimed water suction well 3; the reclaimed water differential pressure flowmeter 5 and the reclaimed water regulating valve 4 are arranged on the reclaimed water supply pipe 7; the desalted water differential pressure flowmeter 9 And the desalinated water regulating valve 10 is arranged on the desalinated water supply pipe 8; wherein, the reclaimed water sent by the reclaimed water supply pipe 7 and the desalted water sent by the desalted water supply pipe 8 are mixed in the reg...

Embodiment 2

[0046] This example also provides a method for preparing reclaimed water, which is realized by the reclaimed water preparation system of Embodiment 1, including the following steps:

[0047] S1: Treat the sewage generated by the iron and steel enterprises through the sewage treatment station to form reclaimed water;

[0048] S2: send the reclaimed water into the regeneration water suction well 3 through the reclaimed water supply pipe 7;

[0049] S3: send the desalted water to the regeneration water suction well 3 through the desalted water supply pipe;

[0050] S4: Reclaimed water and desalinated water are mixed according to a set ratio to form regenerated water. The electrical conductivity of the reclaimed water is less than 1100μS / cm, and the chloride ion content is 200-220mg / L.

[0051] Wherein, step S4 specifically includes: obtaining the reclaimed water flow rate sent by the reclaimed water pressure differential flowmeter 5 on the reclaimed water supply pipe 7 through t...

Embodiment 3

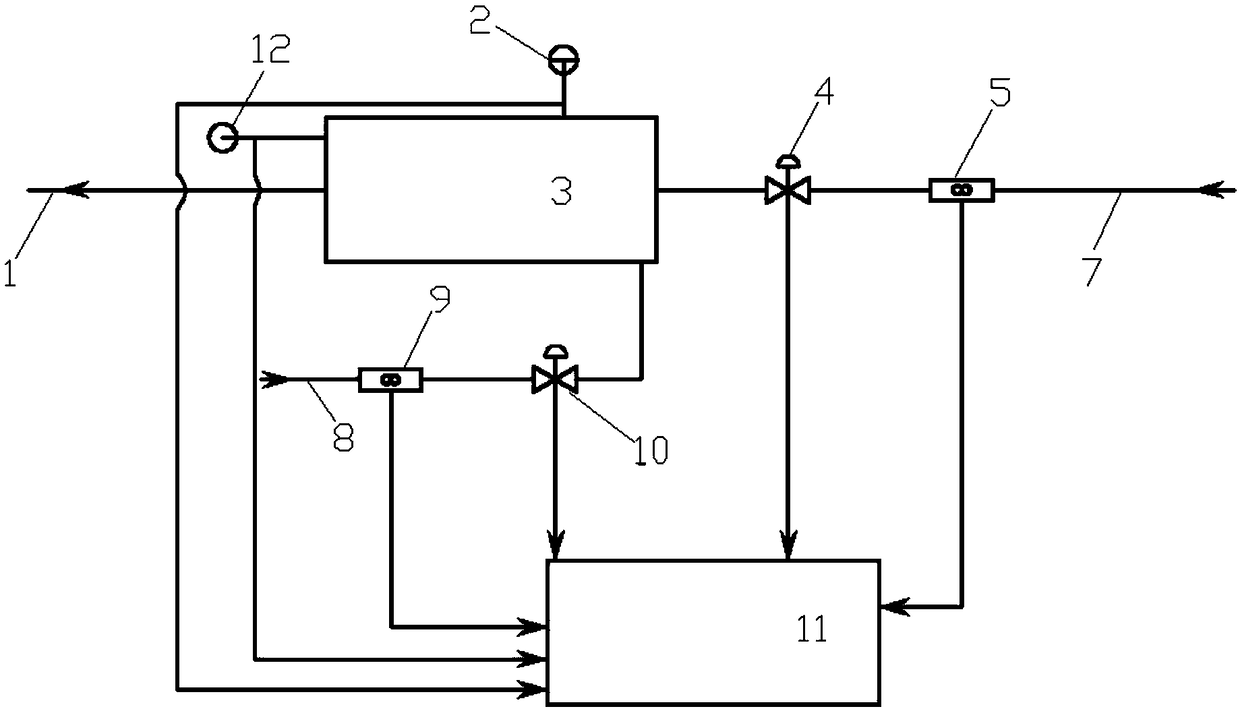

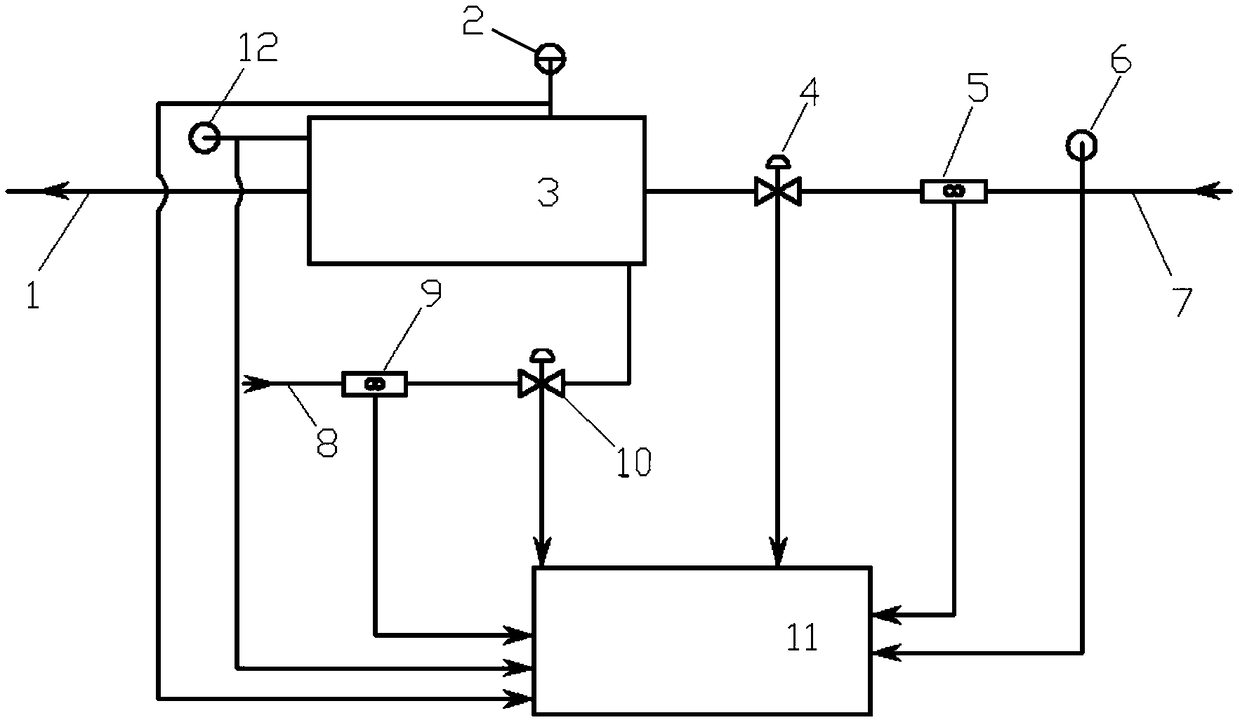

[0053] See attached figure 2 , this example provides the second reclaimed water preparation system, including: reclaimed water suction well 3, reclaimed water supply pipe 7, desalinated water supply pipe 8, reclaimed water differential pressure flowmeter 5, reclaimed water regulating valve 4, desalinated water differential pressure flow rate Meter 9 and desalted water regulating valve 10, wherein:

[0054] The reclaimed water supply pipe 7 and the desalted water supply pipe 8 are connected to the input end of the reclaimed water suction well 3; the reclaimed water differential pressure flowmeter 5 and the reclaimed water regulating valve 4 are arranged on the reclaimed water supply pipe 7; the desalted water differential pressure flowmeter 9 And the desalinated water regulating valve 10 is arranged on the desalinated water supply pipe 8; wherein, the reclaimed water sent by the reclaimed water supply pipe 7 and the desalted water sent by the desalted water supply pipe 8 are m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com