Whitening method of albite powder

A technology of feldspar powder and albite, which is applied in the whitening field of albite powder, can solve the problems of environmental pollution, increase whitening process steps, increase costs and the like, and achieve the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

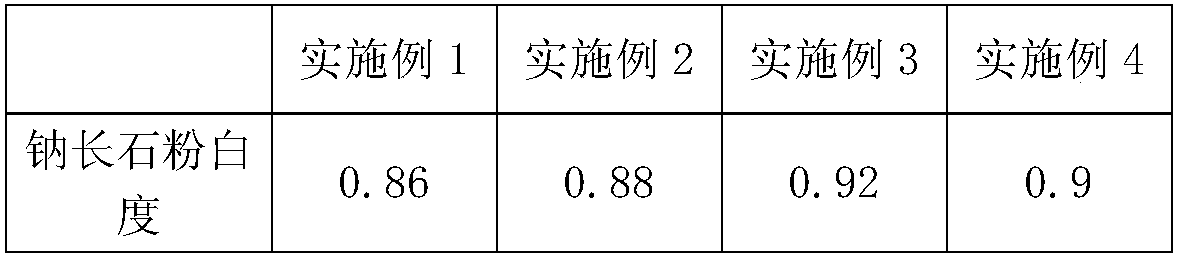

Examples

Embodiment 1

[0021] A whitening method of albite powder, comprising the following steps:

[0022] (1) Ball milling: the albite ore is ball-milled into stone powder by a ball mill;

[0023] (2) Sieving: the stone powder in step (1) is sieved to remove large particles to obtain albite powder with a particle size of not less than 200 mesh;

[0024] (3) pulping: pour the albite powder of step (2) into the pulping tank and add water to make a concentration of 20% pulp, then add the tripolyphosphoric acid whose quality is 0.05% of the pulp in the pulp Sodium, stir evenly with a mixer, and heat to 50°C;

[0025] (4) Pickling: Add oxalic acid to the pulp of step (3), the ratio of the oxalic acid to the pulp is 1:20 by weight, the mass fraction of the aqueous oxalic acid solution is 2%, and the pickling time is 1.5h ;

[0026] (5) filter: filter the ore pulp that step (4) acid washes;

[0027] (6) Calcination: Send the pulp filtered in step (5) into a calciner for calcination for 1 hour, and co...

Embodiment 2

[0029] A whitening method of albite powder, comprising the following steps:

[0030] (1) Ball milling: the albite ore is ball-milled into stone powder by a ball mill;

[0031] (2) Sieving: the stone powder in step (1) is sieved to remove large particles to obtain albite powder with a particle size of not less than 200 mesh;

[0032] (3) pulping: pour the albite powder of step (2) into the pulping tank and add water to make a concentration of 22% pulp, then add the tripolyphosphoric acid whose quality is 0.07% of the pulp in the pulp A mixture of sodium and sodium hexametaphosphate in a ratio of 1:1, stirred evenly with a mixer, and heated to 70°C;

[0033] (4) Pickling: Add oxalic acid to the pulp of step (3), the ratio of oxalic acid to the pulp is 1:24 by weight, the mass fraction of the aqueous oxalic acid solution is 4%, and the pickling time is 1.8h ;

[0034] (5) filter: filter the ore pulp that step (4) acid washes;

[0035] (6) Calcination: Send the pulp filtered i...

Embodiment 3

[0037] A whitening method of albite powder, comprising the following steps:

[0038] (1) Ball milling: the albite ore is ball-milled into stone powder by a ball mill;

[0039] (2) Sieving: the stone powder in step (1) is sieved to remove large particles to obtain albite powder with a particle size of not less than 200 mesh;

[0040] (3) pulping: pour the albite powder of step (2) into the pulping tank and add water to make a concentration of 25% pulp, then add the hexametaphosphoric acid whose quality is 0.08% of the pulp in the pulp A mixture of sodium and sodium pyrophosphate in a ratio of 1:1, stirred evenly with a mixer, and heated to 85°C;

[0041] (4) pickling: the ore pulp of step (3) is added oxalic acid, and the ratio of described oxalic acid and described ore pulp by weight is 1:25, and the mass fraction of described oxalic acid aqueous solution is 3%, and pickling time is 2h;

[0042] (5) filter: filter the ore pulp that step (4) acid washes;

[0043] (6) Calcina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com