Automatic manipulating device for hollow fiber membrane filaments

一种自动操纵、纤维膜的技术,应用在膜、膜技术、半透膜分离等方向,能够解决中空纤维膜无法实现自动化生产等问题,达到人工干预过程少、耗材使用少、组件质量高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

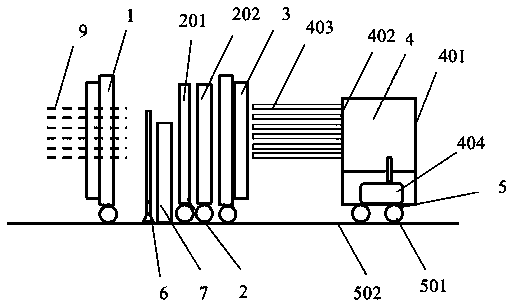

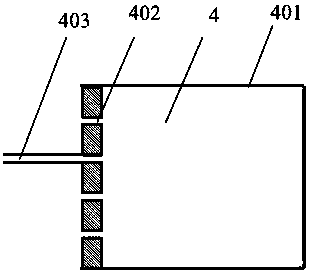

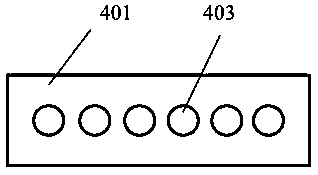

[0066] This embodiment provides an automatic manipulation device for hollow fiber membranes, such as figure 1 , including the first membrane filament tractor 1 arranged in sequence, the membrane filament support assembly 2 for fixing the membrane filament and the second membrane filament traction machine 3, the membrane filament support assembly 2 includes the first membrane filament arranged in parallel and with an upper opening The support 201 and the second membrane filament support 202, the first membrane filament tractor 1, the first membrane filament support 201, the second membrane filament support 202, and the second membrane filament tractor 3 are all provided with membranes that match the membrane filaments. Silk holes; the automatic manipulator also includes the first membrane wire grabbing mechanism 4, the driving membrane wire grabbing mechanism 4, the second membrane wire tractor 3, the second membrane wire support 202 and the first membrane wire support 201 appro...

Embodiment 2

[0077] This embodiment provides another automatic manipulation device for hollow fiber membranes, such as Figure 9 , including the first membrane filament traction machine 1 arranged in sequence, the membrane filament support assembly 2 for fixing the membrane filament and the second membrane filament traction machine 3, the membrane filament support assembly 2 includes the first membrane filament support that can be opened and closed at the upper part 201 and the second membrane filament support 202, the first membrane filament tractor 1, the first membrane filament support 201, the second membrane filament support 202, and the second membrane filament tractor 3 are all provided with membrane filaments that match the membrane filaments hole; the automatic manipulator also includes a first membrane filament grabbing mechanism 4, a driving membrane filament grabbing mechanism 4, a second membrane filament tractor 3, a second membrane filament support 202 and a first membrane fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com