An automatic processing device for threading the steel wire of the handle of the bucket into the handle

An automatic processing and processing device technology, applied in the field of automatic processing devices, can solve the problems of high product failure rate, difficulty in ensuring that the handle is located in the center of the steel wire, low work efficiency, etc., and achieve a simple structure, low cost and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

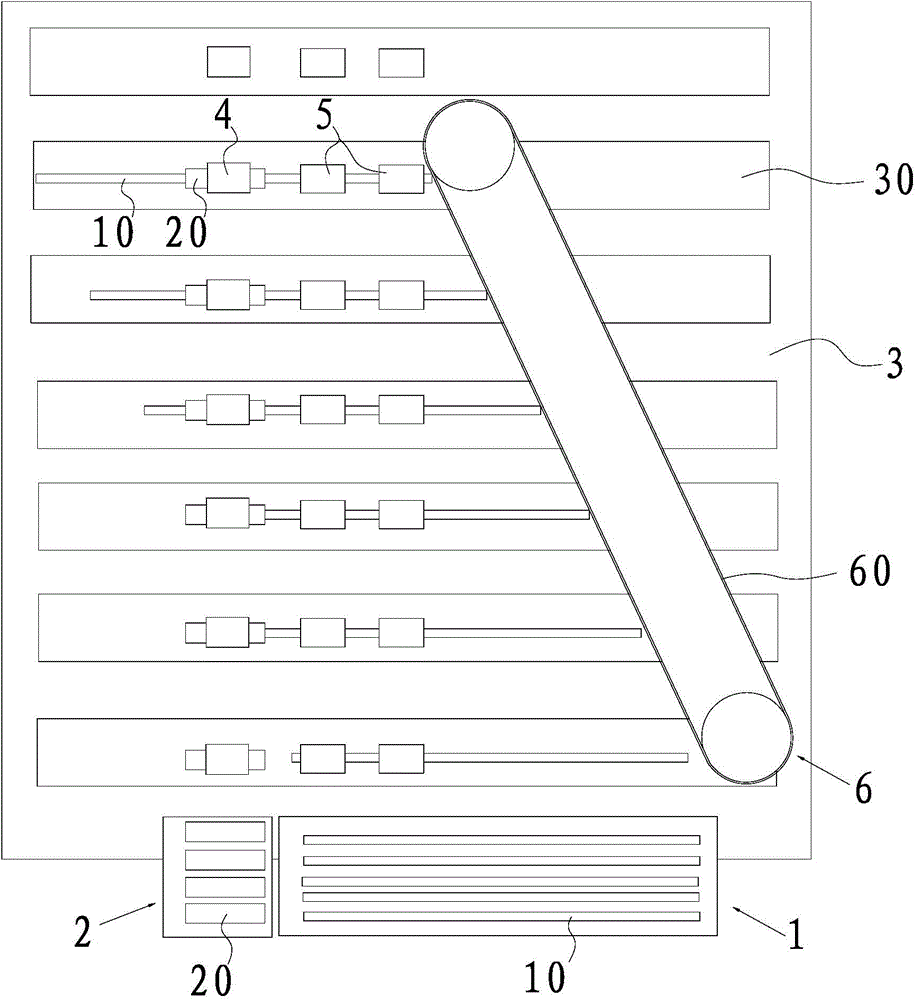

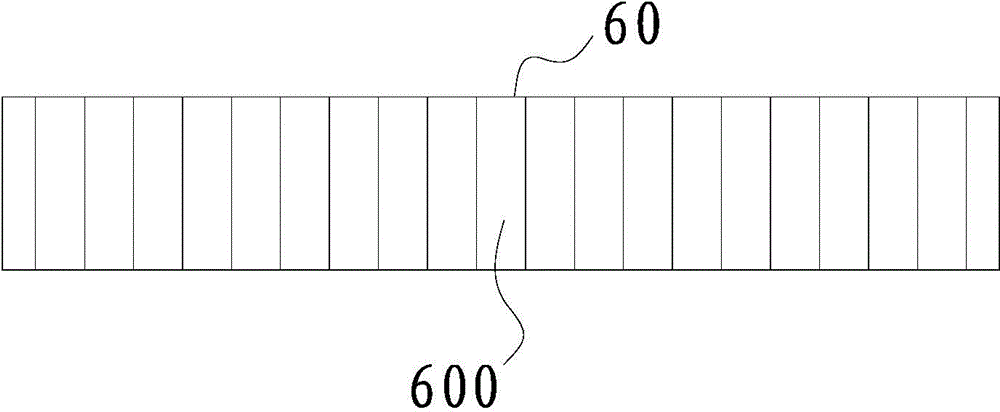

[0014] Such as figure 1 and figure 2 As shown, the automatic processing device for passing the steel wire of the bucket handle into the handle provided by the present embodiment includes a steel wire supply unit 1 (for sorting the steel wires and outputting them one by one, those skilled in the art can easily imagine, Not described in detail here), handle supply unit 2 (for the handles are sorted and can be output one by one, those skilled in the art can easily think of it, and will not be described in detail here), the conveyor belt 3 for transmitting the steel wire 10 and the handle 20 and the first driving mechanism that drives the conveyor belt 3 to rotate, and is arranged on the conveyor belt 3 to respectively hook the steel wire 10 located in the steel wire supply unit 1 and the handle 20 located in the handle supply unit 2 one by one and synchronously. The hook 5 , the second hook 4 , and the insertion unit 6 for passing the steel wire 10 in the first hook 5 into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com