An optical fiber automatic tube-pipe packaging device and its application method

An automatic optical fiber threading technology, applied in optical fiber/cable installation, laser welding equipment, manufacturing tools, etc., can solve problems such as inability to realize automation, and achieve the effect of improving efficiency and success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

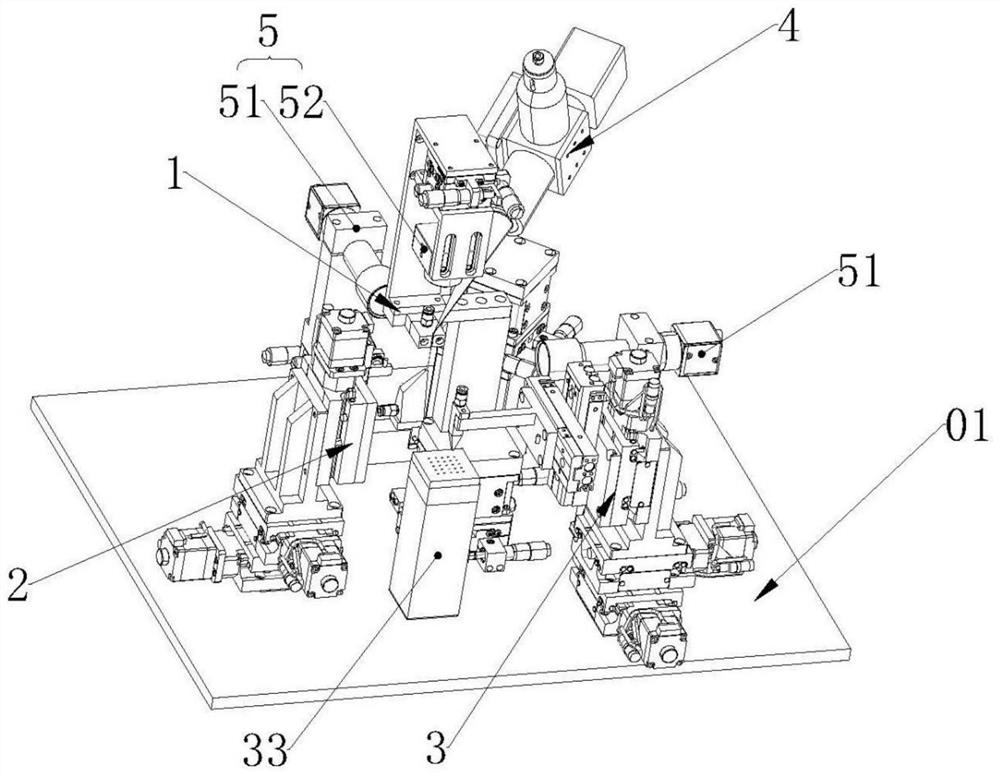

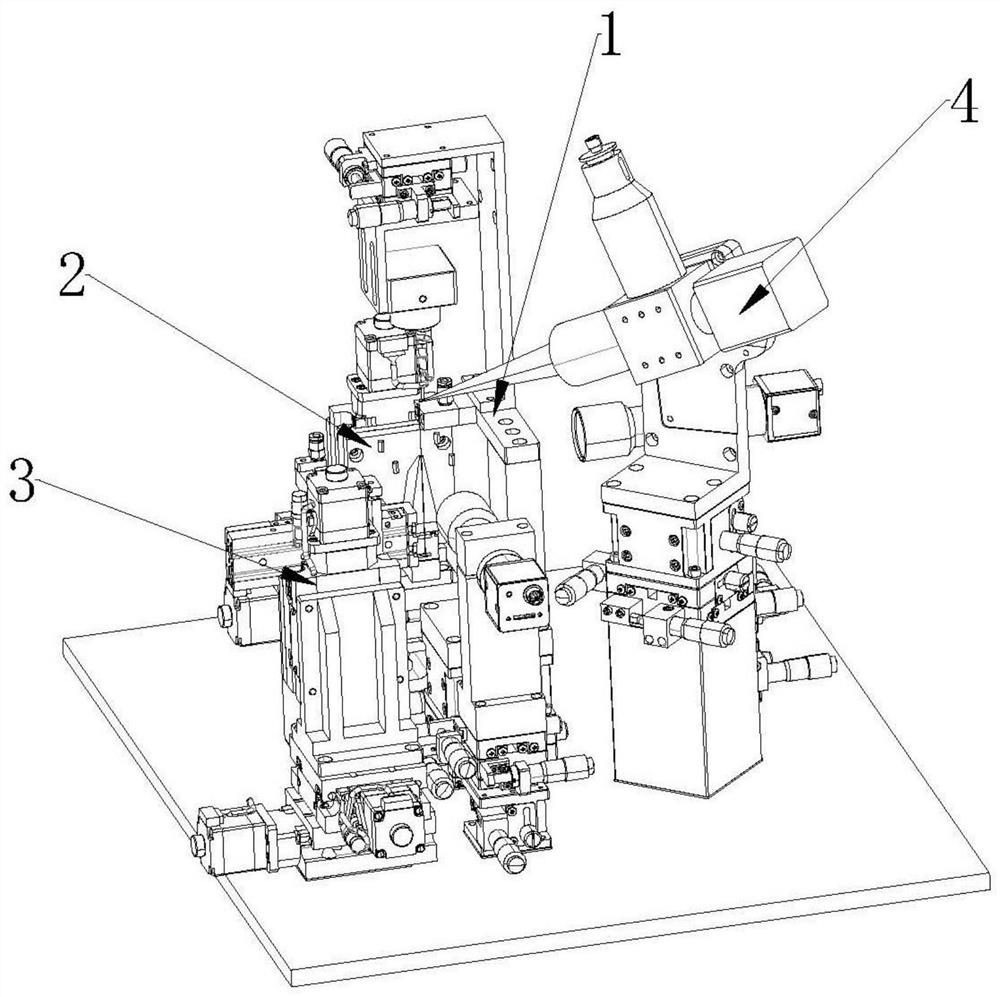

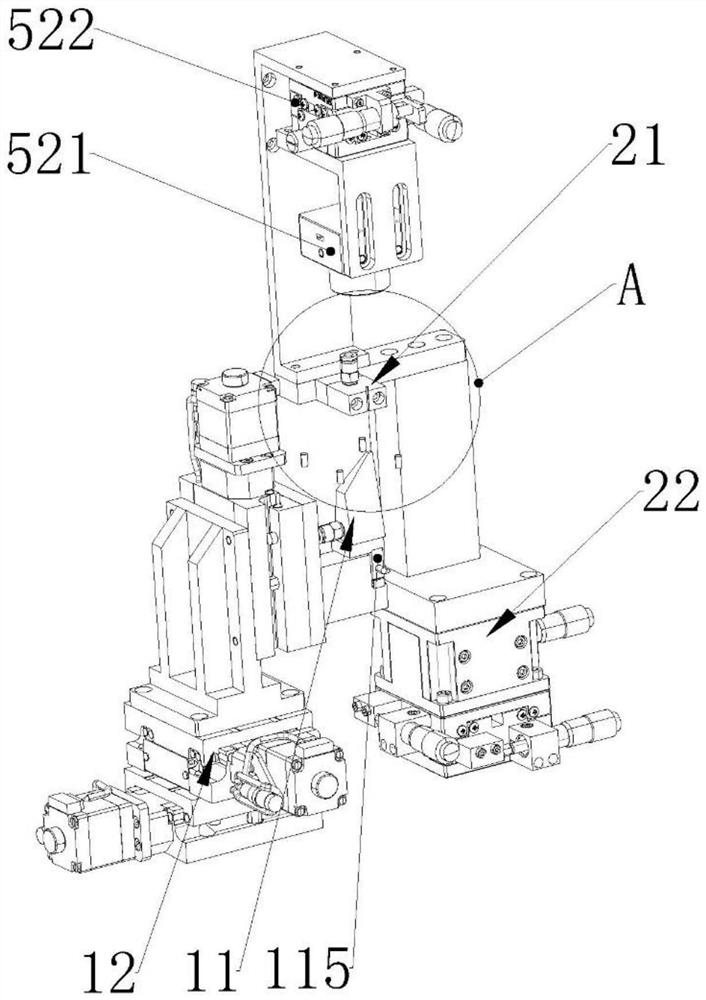

[0045] Such as Figure 1-8 As shown, the embodiment of the present invention provides an automatic optical fiber pipe-passing packaging device, which includes a working surface 01 on which a working area is set. The following structures are arranged around the working area: a first fixture 1 , a second fixture 2 , a third fixture 3 , and welding equipment 4 . Wherein, the first clamp 1 is used for clamping the optical fiber, and includes a first clamping structure 11 and a first three-axis moving structure 12, and the first three-axis moving structure 12 can drive the first clamping structure 11 to move in the working area. The second clamp 2 is used to clamp the package, the package is usually in the shape of a tube, the second clamp 2 includes a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com