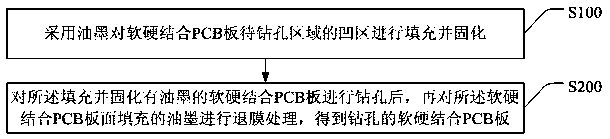

A method for improving height difference drilling of a soft-hard bonded PCB

A PCB board, soft and hard combination technology, applied in electrical components, printed circuit manufacturing, printed circuits and other directions, can solve problems such as easy generation of burrs, and achieve the effect of controlling costs, suppressing burrs, and improving processing problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] According to polyurethane acrylate, acrylic monomer, photoinitiator TPO, talcum powder, polysiloxane and blue toner, mix and stir for 2 hours according to the ratio of 42:13:6:35:3.95:0.05 by weight, and adjust it to 12000CPS The viscosity of the glue solution is different, and the PCB board surface with different height difference is printed with different meshes, and the concave area of the PCB board surface is filled and UV light curing. The intensity of the UV light curing is 900mj / cm 2 , and then carry out the drilling process test with the cover / backing plate. The results of the burr detection are shown in Table 1, and finally the film is removed.

[0049] Table 1 Example 1 burr detection results:

[0050]

[0051] From the above experimental results, it can be seen that the UV light-curable ink prepared in Example 1 selects a suitable screen printing to fill the height difference of the PCB board surface. The film is fast and has no glue residue.

Embodiment 2

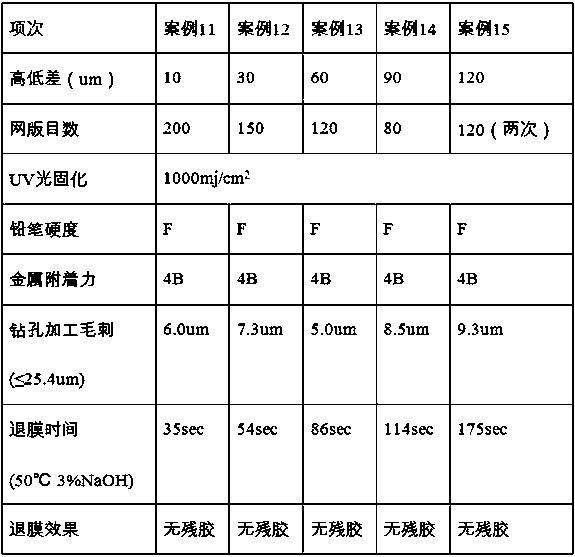

[0053] Mix and stir aliphatic acrylate, acrylic acid monomer, photoinitiator 184, fumed silicon, polysiloxane and blue toner for 2 hours according to the ratio of 40:15:10:31:3.9:0.1 by weight, and adjust to Glue viscosity of 14000CPS, use screen printing of different meshes to print PCB boards with different height differences, fill the concave area of PCB board and UV light curing, the intensity of UV light curing is 800mj / cm 2 , and then carry out the drilling process test with the cover / backing plate. The results of the burr detection are shown in Table 2, and finally the film is removed.

[0054] Table 2 Example 2 burr detection results:

[0055]

[0056] From the above experimental results, it can be seen that the UV light-curable ink prepared in Example 2 selects a suitable screen printing to fill the height difference of the PCB board surface, and has excellent drilling processing performance after curing, which can effectively suppress processing burrs and proces...

Embodiment 3

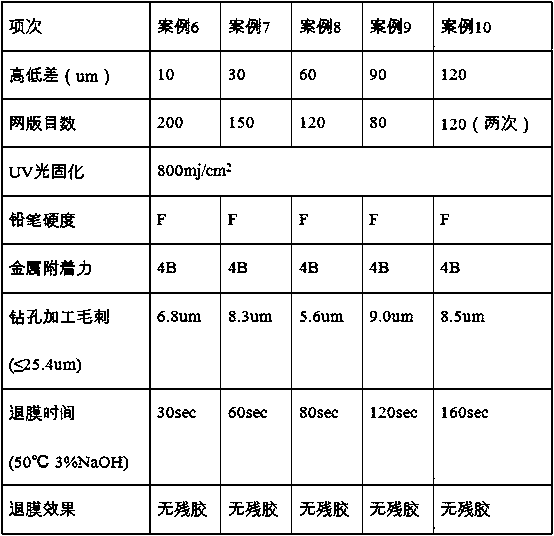

[0058] According to the ratio of polyether acrylate, acrylic acid monomer, photoinitiator TPO, talcum powder, polysiloxane and blue toner according to the weight percentage of 45:10:5:35.5:4.45:0.05, mix and stir for 2h, adjust to Glue viscosity of 10000CPS, use screen printing of different meshes to print PCB boards with different height differences, fill the concave area of PCB board and UV light curing, the intensity of UV light curing is 1000mj / cm 2 , and then carry out the drilling process test with the cover / backing plate. The results of the burr detection are shown in Table 2, and finally the film is removed.

[0059] Table 3 Example 3 burr detection results:

[0060]

[0061] From the above experimental results, it can be seen that the UV light-curable ink prepared in Example 2 selects a suitable screen printing to fill the height difference of the PCB board surface, and has excellent drilling processing performance after curing, which can effectively suppress pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com