Network transformer pin automatic winding lead wire equipment and winding method thereof

A technology of network transformers and leads, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of high scrap rate, unstable quality, low pin winding efficiency, etc., achieving a high degree of automation and reducing The effect of labor intensity and reduction of product scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

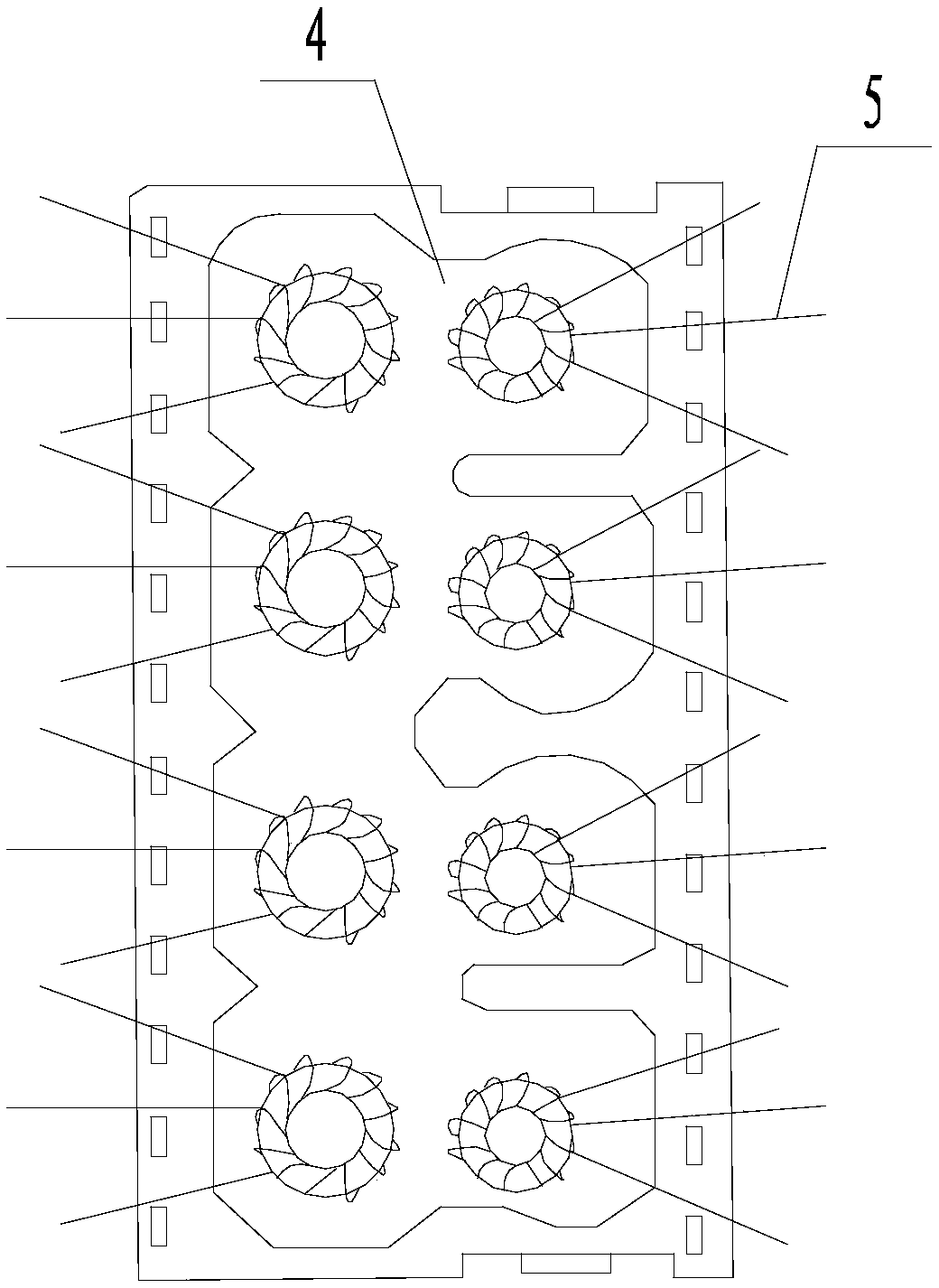

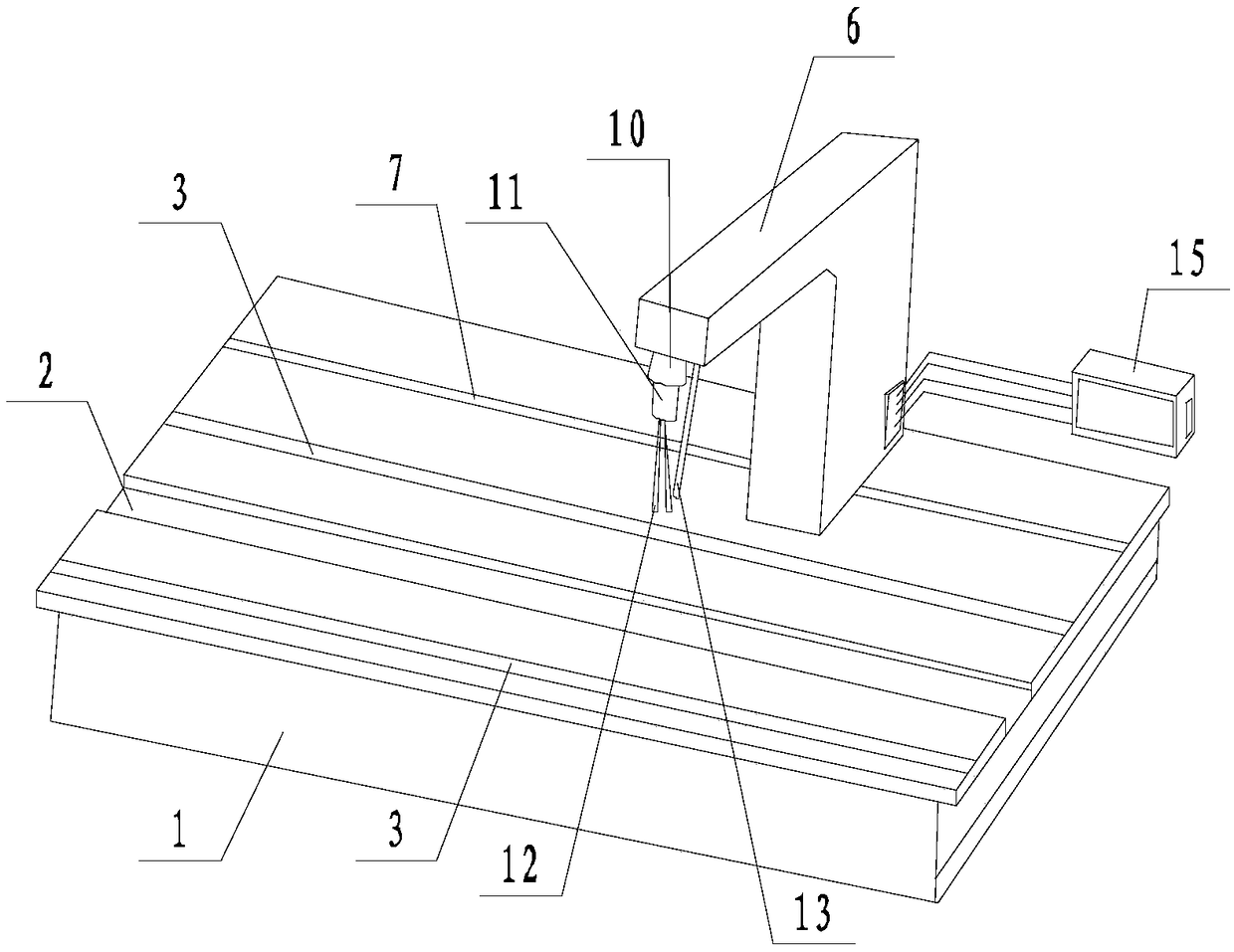

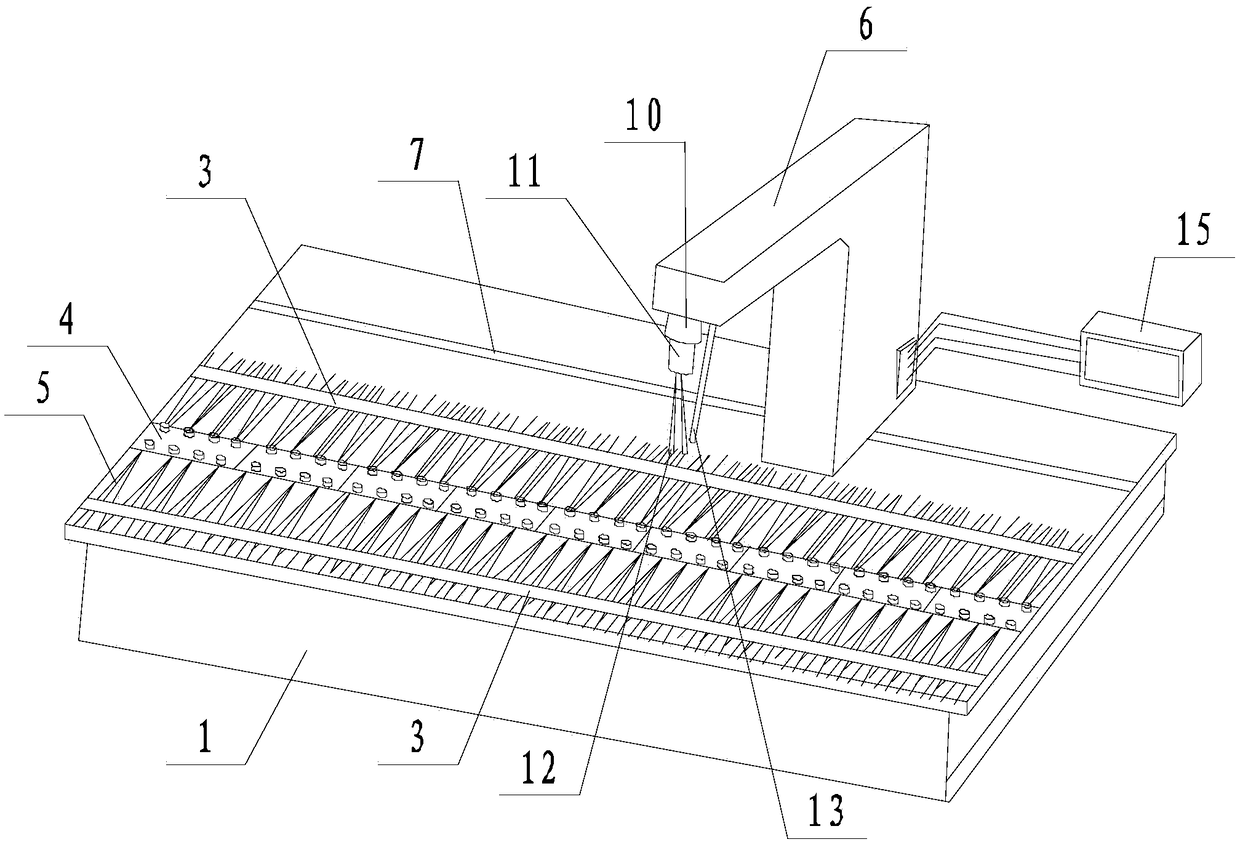

[0032] Such as Figure 1 to Figure 3 The shown network transformer pin automatic winding lead wire equipment includes a workbench 1, the upper surface of the workbench 1 is provided with a linear groove 2, and both sides of the linear groove 2 are provided with lead wires on the surface of the workbench 1. 3. The length direction of the lead bar 3 is parallel to the long axis of the linear groove 2, and the width of the linear groove 2 matches the width of the network transformer assembly box 4 to be wound. When the network transformer assembly box 4. When placed in the linear groove 2, the lead bar 3 can press the iron core lead 5 of the network transformer; the workbench 1 is also provided with a first slide rail 7 parallel to the long axis of the linear groove 2 , also includes a slider 8, the bottom of the slider 8 is located in the first slide rail 7, the slider 8 is connected to the head 6, the bottom surface of the head 6 is provided with a second slide rail 9, the firs...

Embodiment 2

[0034] Such as Figure 1 to Figure 7 The shown network transformer pin automatic winding lead wire equipment, on the basis of the embodiment, the lead wire identification device 14 includes an image acquisition device, an image recognition module connected with the image acquisition device, and the shooting direction of the image acquisition device is towards the motor Below the tweezers 12 , the output end of the image recognition module is connected to the controller 15 . Described electric tweezers 12 comprises two clips, and two clips are respectively hinged on the bottom end of rotating device 11, and the side surface of two clips opposite to each other is all embedded with electromagnet 16, and described electromagnet 16 is all connected with The control terminals of the controller 15 are connected. The lead wire bead 3 has a long strip structure, and the lead wire bead 3 is fixedly connected to two cylinders on the bottom surface along the long axis direction. The tel...

Embodiment 3

[0036] The method for winding the pins of the network transformer comprises the following steps on the basis of any of the above-mentioned embodiments: (a) the coil formed by winding the ferromagnetic ring and the enameled wire is fixed in the network transformer assembly box 4 according to the designed position, Then the network transformer assembly box 4 is put into the linear groove 2 successively, until the network transformer assembly box 4 is filled up in the linear groove 2; The two sides of the groove 2 are pulled out so that the leads on both sides are pressed by the two lead wires 3 respectively; (c) start the driving mechanism to make the slider 8 move along the first slide rail 7 and the second slide rail 9 to drive the motor The tweezers 12 and the probe 13 move, and after the probe 13 recognizes the set initial lead through the lead identification device 14, the feedback signal is sent to the controller 15; the controller 15 controls the extension of the telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com