Method for detecting fullness of sleeve grouting based on three-dimensional dimensional measurement technology of endoscope

A technology of three-dimensional size and measurement technology, which is used in measurement devices, optical testing of flaws/defects, and material analysis by optical means. It can solve the problems of affecting detection accuracy, high cost of embedded parts, and expensive embedded parts. Achieve the effect of improving detection accuracy, increasing deterrence, and small drilling depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

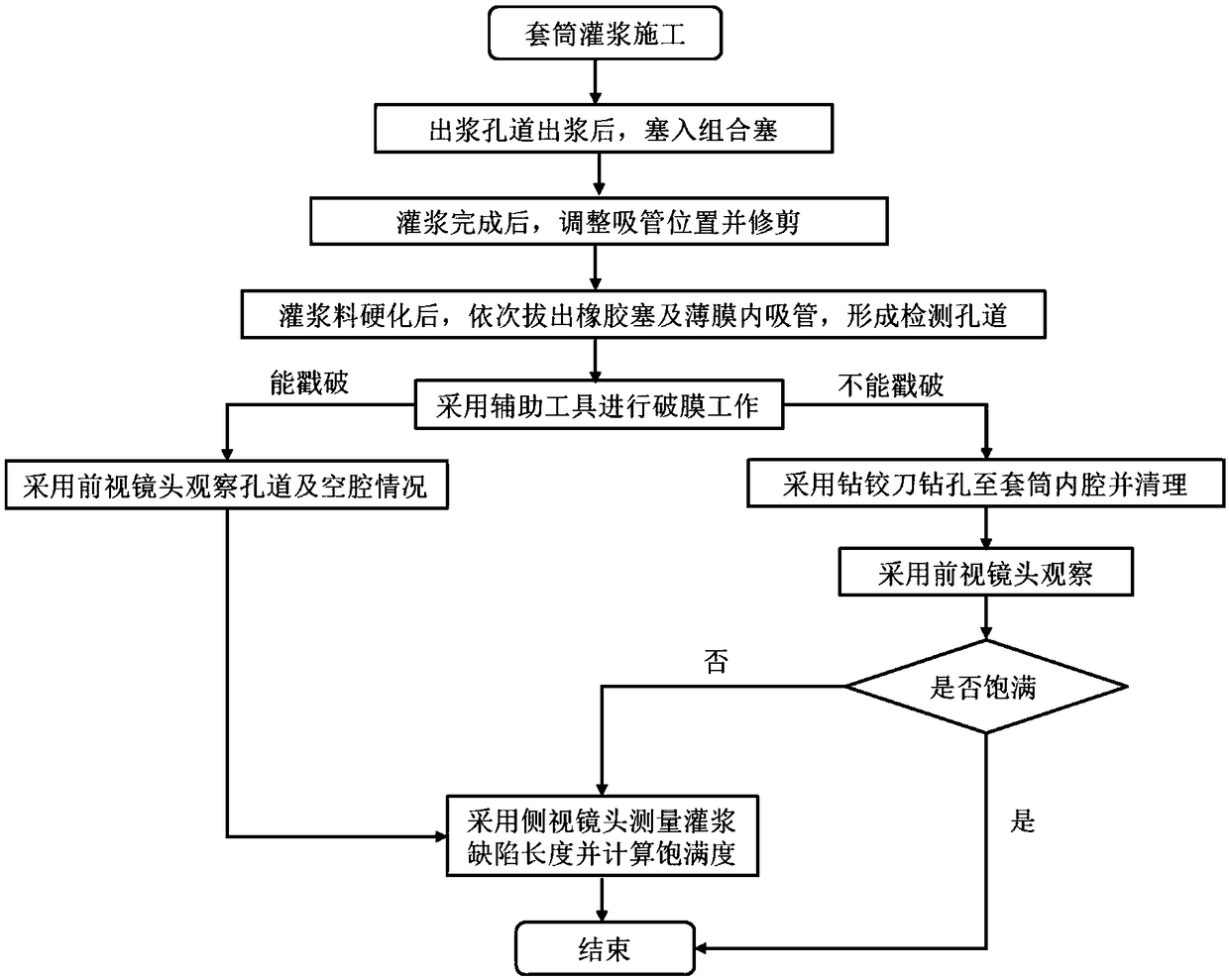

[0056] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

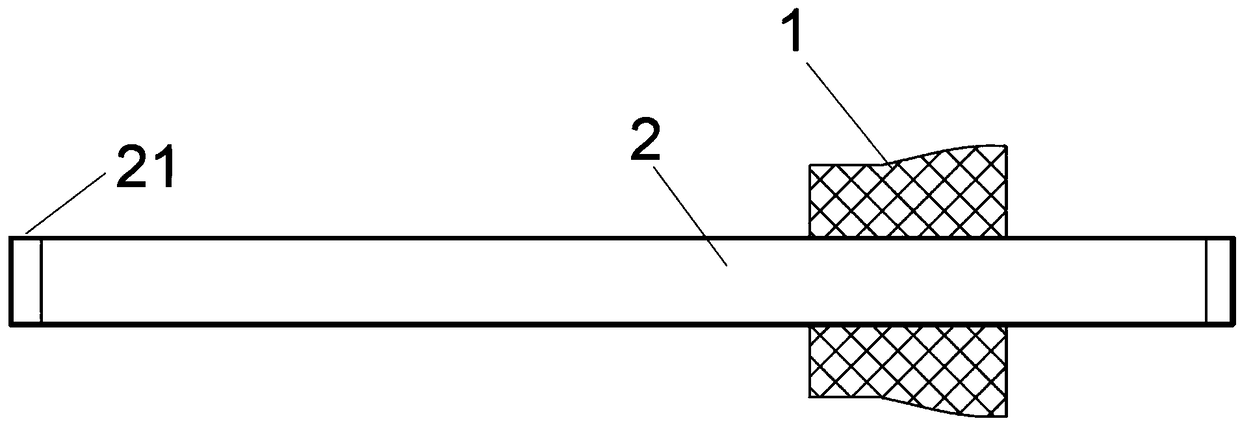

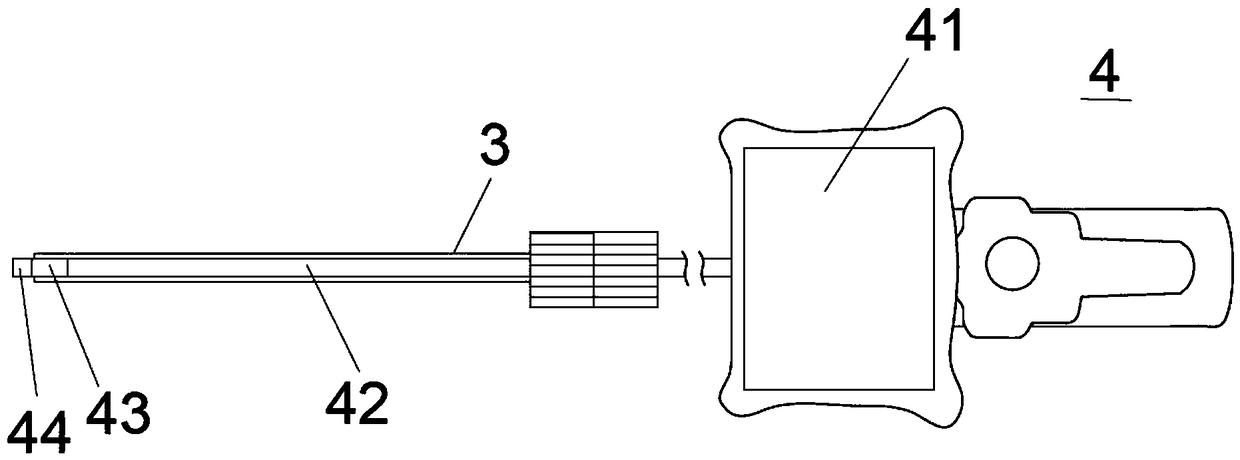

[0057] An embodiment of the sleeve grouting plumpness detection method based on endoscope three-dimensional dimension measurement technology of the present invention, refer to figure 1 and figure 2 As shown, it includes a rubber stopper 1, a straw 2, a rigid sleeve 3 and a three-dimensional stereoscopic measurement endoscope 4; the three-dimensional stereoscopic measurement endoscope includes an endoscope host 41, a connecting hose 42, a probe 43 and a lens 44 connected in sequence , the diameter of the connecting hose, probe and lens is not greater than 4mm. The lens includes a front-view observation lens 441 and a side-view three-dimensional measurement lens 442. The two lenses...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com