Proportional electromagnetic valve driving method based on PWM

A technology of proportional solenoid valve and driving method, which is applied in the direction of valve details, valve devices, engine components, etc., can solve the problems of long adjustment rise time, inability to respond quickly, and slow adjustment, so as to shorten the adjustment time, save the rise time, achieve rapid results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation will be described below in conjunction with the accompanying drawings.

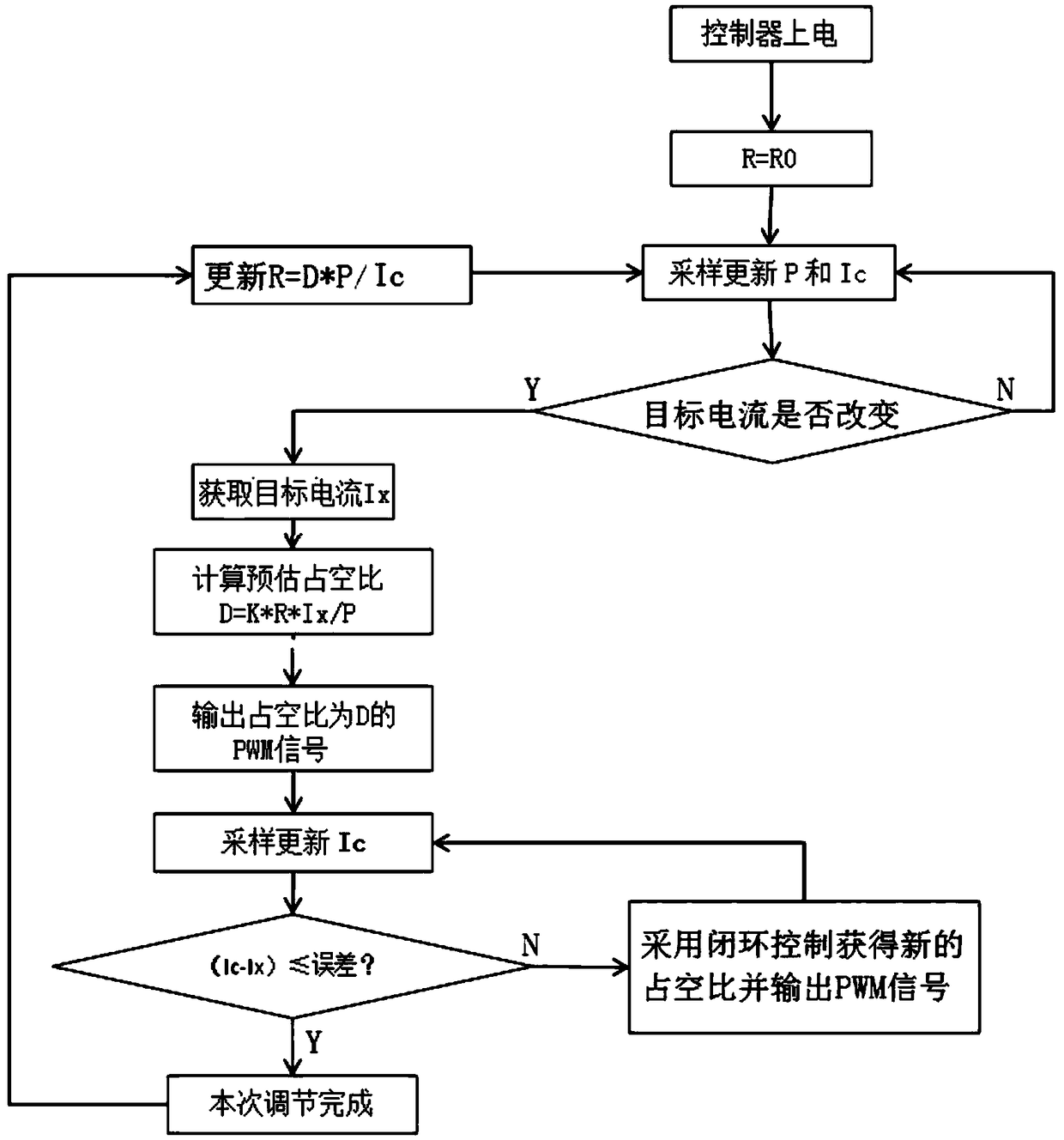

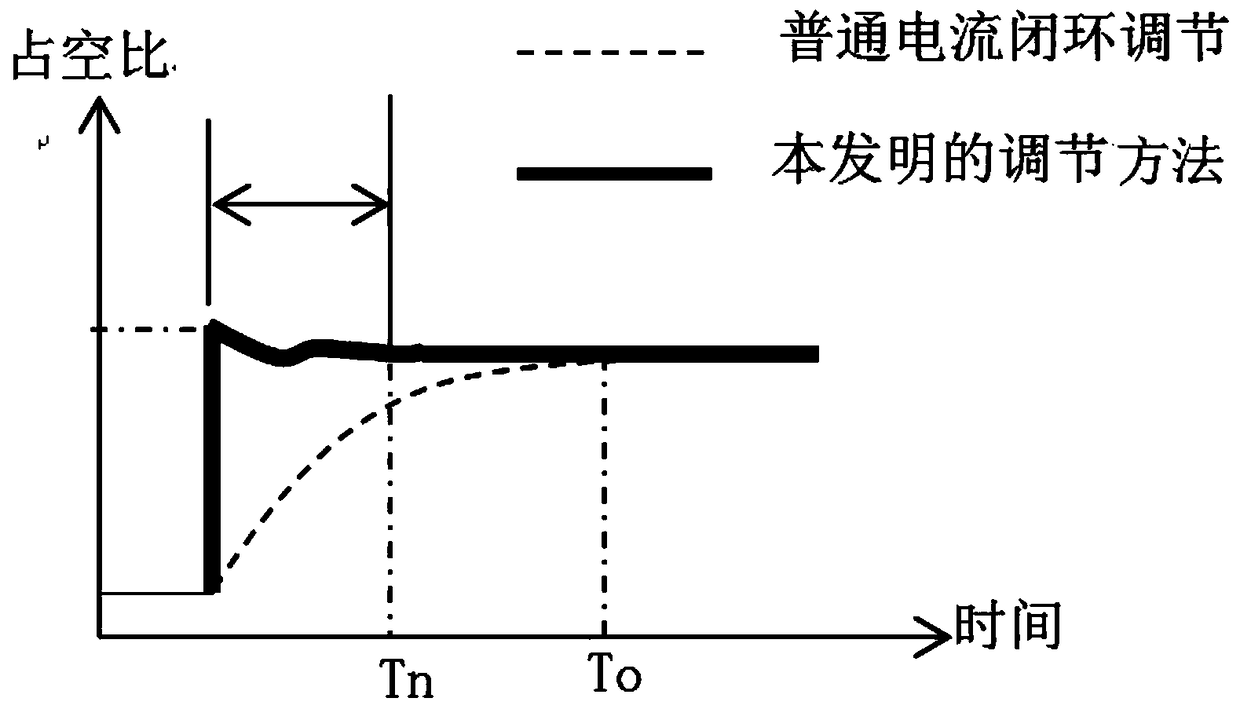

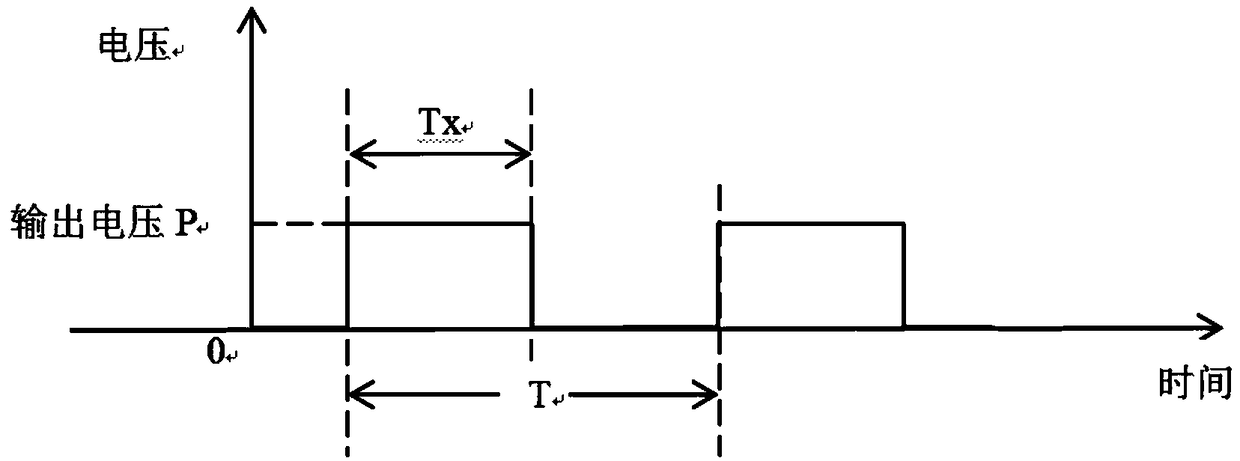

[0014] Such as image 3 As shown, the controller controlling the proportional solenoid valve usually uses PWM (pulse width modulation) to adjust the current. That is to say, the controller outputs a rectangular wave voltage at a certain frequency, wherein in one cycle, the cycle is T, the high level time is Tx, then the duty ratio is D=Tx / T, and the average current I in the cycle T= P*D / R, P is the driving voltage loaded on both ends of the proportional solenoid valve, and R is the impedance of the proportional solenoid valve. The impedance of the proportional solenoid valve will change with frequency (1 / T) and hydraulic oil temperature, but the fluctuation will not be too large, the maximum fluctuation is 20% (the fluctuation of different valve impedance values will be different), so through the formula I=P*D / The calculated current of R will not be too accurate. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com