Screw and corresponding punch

A technology for screws and punching tools, applied in the direction of screws, nuts, bolts, etc., which can solve problems such as inability to generate sufficient torque, increase in manufacturing costs, and easy damage to grooves and joint blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Now will only be an example but not in order to limit the specific embodiment, and with reference to the accompanying drawings, the preferred structural content of the present invention is described as follows:

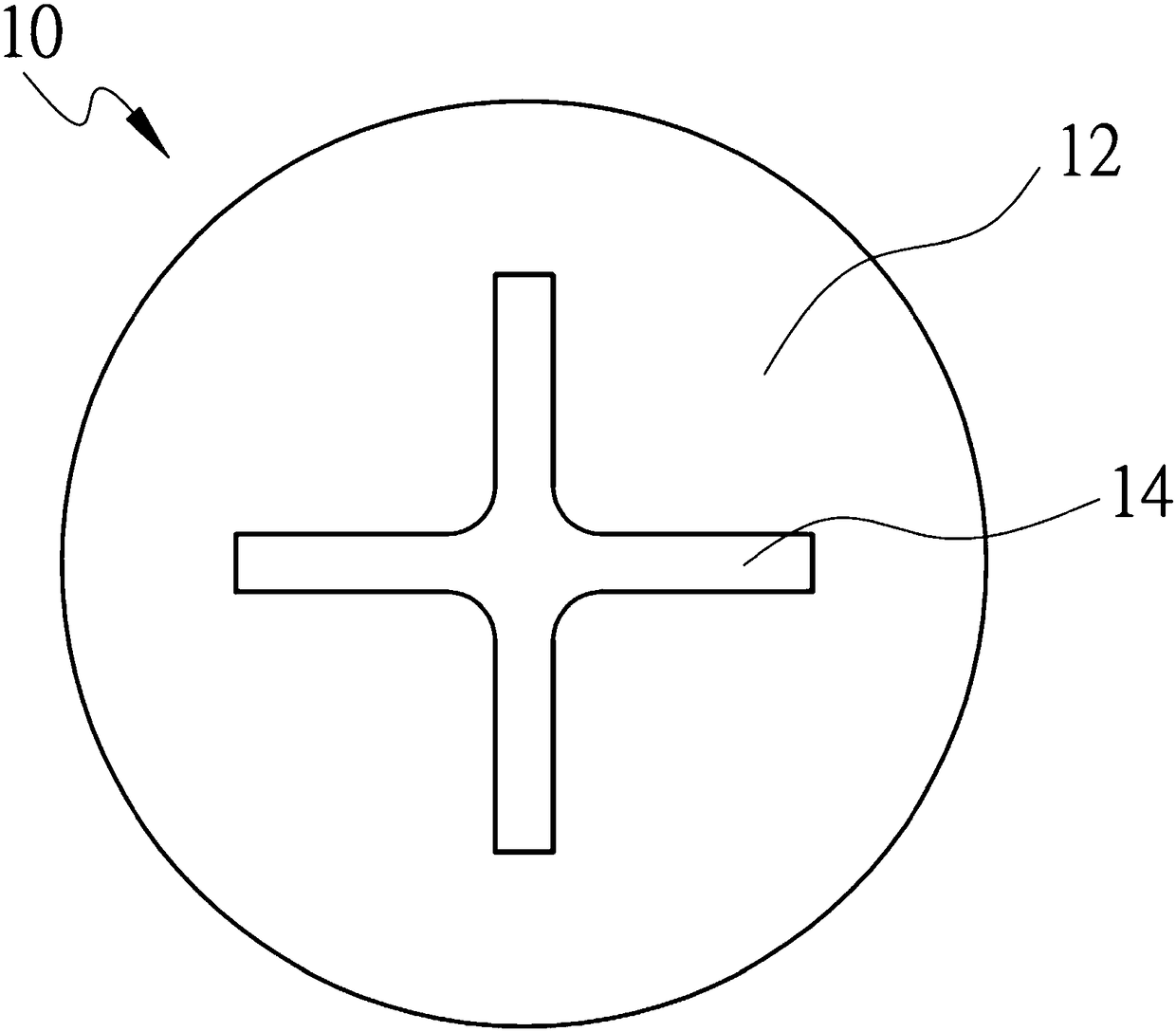

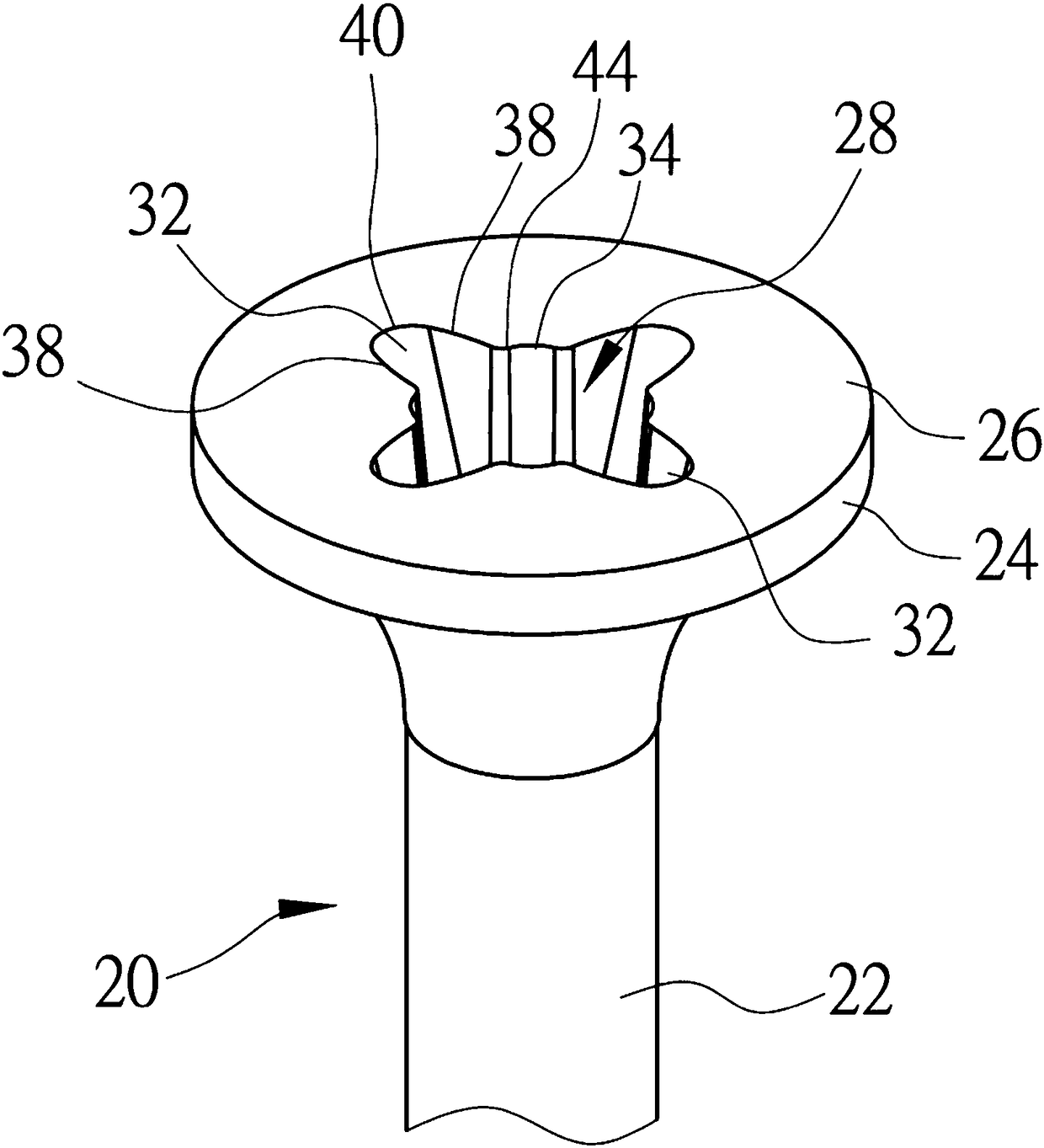

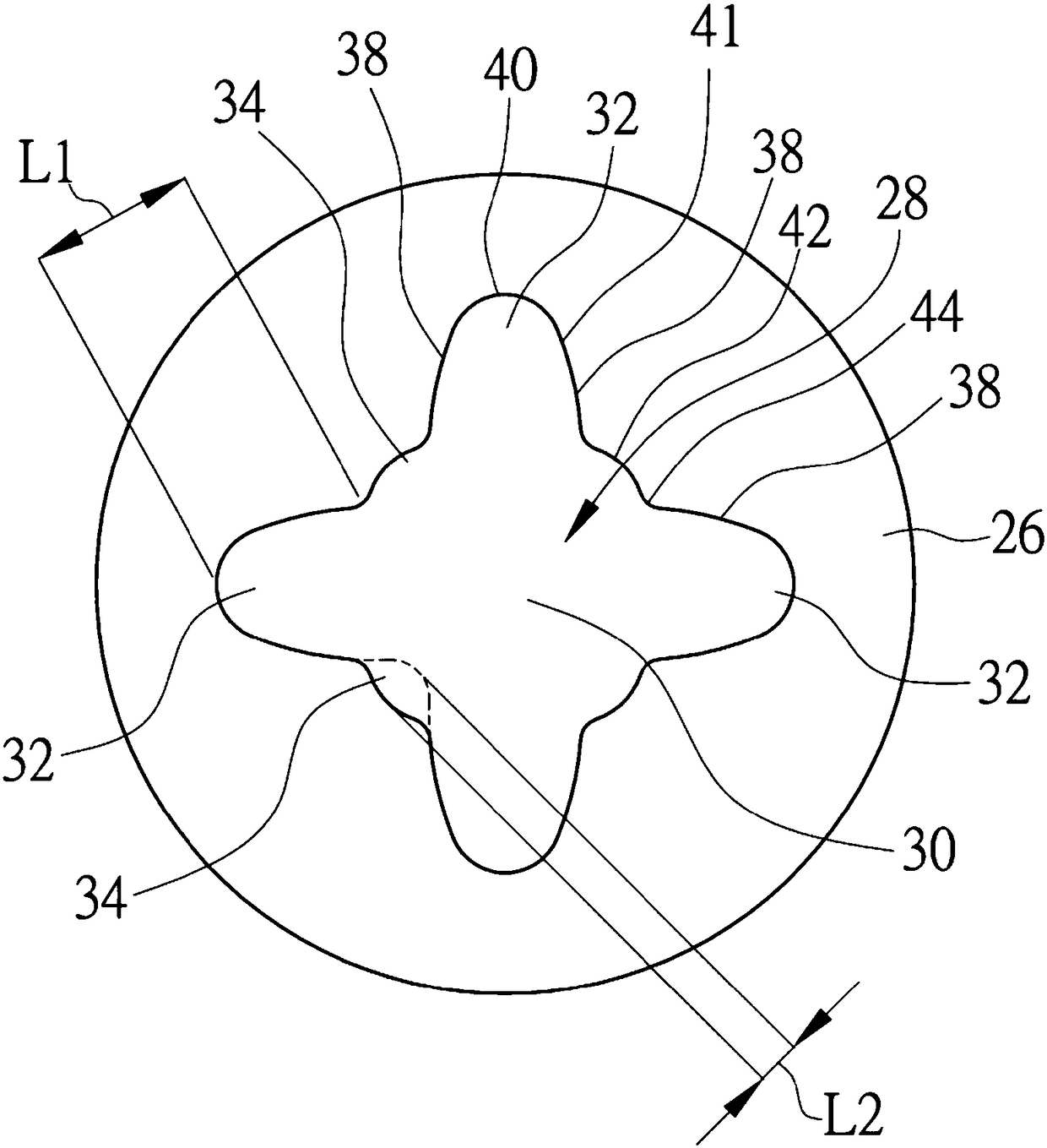

[0033] Figure 2 to Figure 4 A screw 20 according to an embodiment of the present invention is shown. The screw 20 includes a shank 22 and a head 24 formed on the upper end of the shank 22 . Threads (not shown) are provided on the rod body 22 , and a groove 28 is formed on the top surface 26 of the head 24 for providing a combined edge of a tool (such as a bit of a screwdriver) to be inserted to drive the screw 20 to rotate. The groove 28 includes a central region 30 , a plurality of peripheral regions 32 radially extending from the central region 30 , and a plurality of connecting regions 34 connected between the peripheral regions 32 . The central region 30 penetrates into the head 24 to a sufficient depth to provide proper engagement for bit insertion, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com