Tandem-type thermostat device of internal combustion engine

An internal combustion engine, tandem technology, used in mechanical equipment, engine components, machines/engines, etc., can solve problems such as increasing fuel consumption and environmental pollution, accelerating cold wear of internal combustion engines, and unstable working temperature, achieving small changes and water temperature. Fast, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

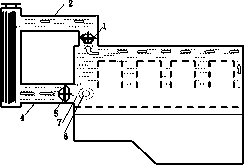

Embodiment 1

[0016] A temperature-saving device for a tandem internal combustion engine includes a thermostat 1 for an outlet pipe and a thermostat 5 for a return pipe. For most of the internal combustion engines where the original thermostat is set at the return pipe 4, the newly installed thermostat should be installed near the end of the internal combustion engine at the outlet pipe 2. In this type of internal combustion engine, the water outlet pipe thermostat 1 is newly installed thermostat 1. The water inlet 11 of the newly installed thermostat 1 is connected with the water outlet 8 of the internal combustion engine by a rubber bushing, and the water outlet 15 is connected with the water inlet 9 of the radiator 3 by the water outlet pipe 2 . On the water inlet 11 and the water outlet 15 of the newly installed thermostat 1, there is a bypass pipe 14 with an inner diameter greater than 3 mm, and the bypass pipe 14 is provided with a bypass valve switch 13 . When adding or replacing th...

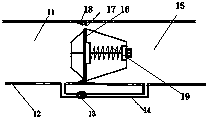

Embodiment 2

[0018] For the small number of internal combustion engines where the original thermostat is installed at the water outlet pipe 2, the newly installed economizer should be installed near the internal combustion engine end at the internal combustion engine return water pipe 4. In this type of internal combustion engine, the return water pipe thermostat 5 is newly installed thermostat 5. The newly installed section 5 water outlet 15 is connected with the water inlet 7 of the internal combustion engine by a rubber sleeve, and the water inlet 11 is connected with the water outlet 10 of the radiator 3 by the return pipe 4 .

Embodiment 3

[0020] According to the needs of the cooling system layout or the limitation of the installation location, the newly installed thermostat can be installed not only at the end near the internal combustion engine, but also at any position near the end of the radiator 3 or on the outlet pipe 2 and return pipe 4. Can be installed inside the internal combustion engine, radiator (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com